Industrial LLMs: Copilots for Asset Performance

ChatGPT has been embedded into many popular asset performance management analytics platforms. Exponential Industry takes you through them.

We kicked off 2023 with a post about using ChatGPT to design a Automotive Final Assembly facility. A year later, large language models (LLMs) have exploded faster than any industrial product in history, with ChatGPT widely seen as the fastest-growing consumer internet app of all time.

It’s not much of a prediction to say 2024 will be the year of enterprise LLM and Generative AI-enabled apps. As a recent FT piece puts it,

One of the most striking findings from Microsoft’s early trials with generative AI has been how “viral” the technology is among workers, according to Jared Spataro, a vice-president at the software company. People take to the technology quickly when they see others around them using it, and once they have tried it out in their own jobs they don’t want to give it up, he says.

Exponential Industry recently completed a series of posts showcasing how the Exponential Industry GPT can assist in root cause identification, IT/OT convergence, and product development. However, there is still friction in bringing real-time context to the chatbot, so it would be best if the chatbot was fully integrated into the products.

This next series of post will take you through the LLMs capabilities released in manufacturing and heavy industry products. We will start with asset performance management platforms and then progress through factory automation systems, engineering and design tools, and lastly general purpose robotics.

The Opportunity of AI-assisted Asset Performance Management

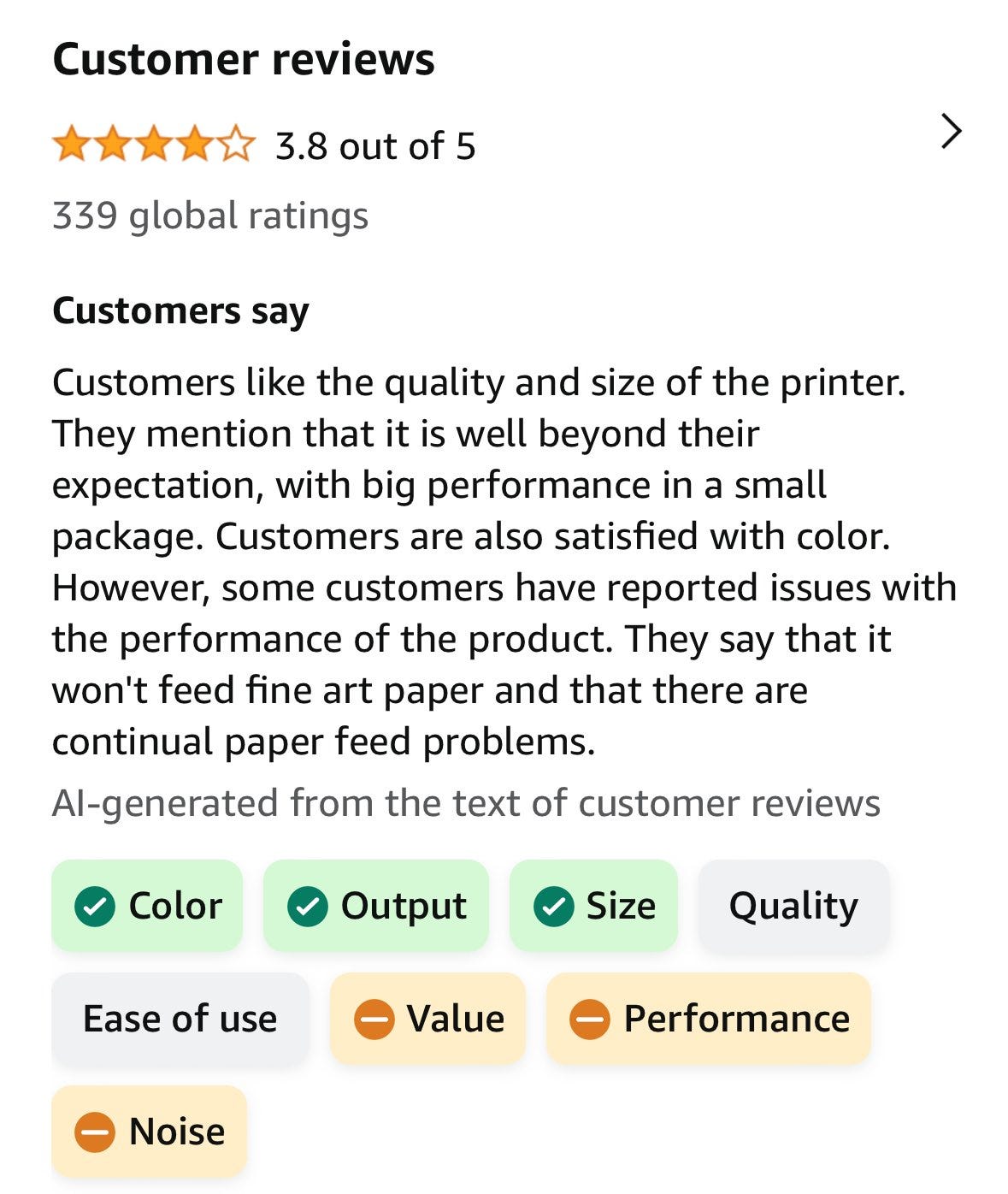

This past holiday season Amazon rolled out AI-generated review summaries. Gone are the days of scanning dozens of reviews to figure out if the product will perform as well as the pictures and specifications seem to indicate. The AI summaries made it incredibly easy to determine whether a product would meet my needs or if I should continue browsing for a substitute.

Now, imagine walking up to a machine that has a blinking red andon light. It requires immediate attention. It has been in operation for years with a variety of problems and now needs to be put back online as soon as possible since production is currently halted. Oh, and the expert that maintained the machine for the last two decades year just retired. Surely an up-to-date AI-generated summary of the machine’s health would be helpful.

The data corpus for critical machinery is usually robust to enable quick response to failures. There are operating parameters being continuously captured, maintenance records logged, and step-by-step troubleshooting procedures at a minimum. But, this operational data is multimodal (text, images, time series, etc.) and often incomplete across each system. Surprisingly, this is not all unlike customer reviews. If Amazon can generate a concise summary from harebrained reviews, our harebrained operational data should suffice.

A machine failure root cause analysis can take hours that most operators cannot afford. Failure history sometimes repeats, but often only rhymes. Having a copilot recall a troubleshooting or repair procedure while you are performing an inspection whilst you have grease all over your hands and the expert is away will be huge help to faster resolution.

The Copilots for Asset Performance

Over the past year, a number of companies big and small have announced or already integrated copilot capability into their industrial analytics products. Below are some the ones Exponential Industry has captured to date (in no particular order).

Cognite

Tulip

Announcing Frontline Copilot™ – AI Tools in Tulip To Assist Your Team in Running Your Operations

Tulip’s Frontline Operations Platform is augmented with Frontline Copilot™ – a set of AI tools for answering questions, exploring data, and creating your own manufacturing assistant.

Frontline Copilot™ is a collection of AI features that help Tulip users do their jobs better, smarter, and faster. Frontline Copilot™ allows engineers and operators to interact with the Tulip platform in new ways, and will enable the rapid creation of custom analyses and dashboards, the power to chat with documents, and the ability to tap into advanced translation and classification capabilities natively within apps.

ABB

ABB and Microsoft collaborate to bring generative AI to industrial applications

ABB is working with Microsoft on the integration of generative AI capabilities into industrial digital solutions for safer, smarter and more sustainable operations

The collaboration aims to deploy Copilot capabilities to enable more intuitive user interaction with ABB Ability™ Genix Industrial Analytics and AI Suite and its applications, and further enhance the value of contextualized data for efficiency and sustainability gains

ABB is leveraging Microsoft Azure OpenAI Service to complement ABB Ability Genix

C3 AI

Operator Assistance with C3 Generative AI

Pilot C3 Generative AI to assist operators with equipment troubleshooting and maintenance

Allow operators to find answers to procedural “how-to questions” in documentation

Enable operators to quickly conduct root cause analysis across documentation and process data

C3 Generative AI for Manufacturing

Integrate disparate equipment manuals on a unified knowledge source

Fine tune results performance and add application users

Roll-out to an initial group of field engineers and customer service representatives

AVEVA

AVEVA World 2023 had a discussion on AVEVA knowledge linking (presentation slides) plans but no formal press release.

“ChatGPT brought large language models (LLM) and generative AI to the forefront of the news earlier this year. Integrating these technologies has the potential to transform industrial applications. AVEVA experts share how we are integrating these technologies into our visualization services via our Industrial AI Assistant. The session will include an introduction and overview of LLM and generative AI, and how they are being applied in business and industry. The heart of the session will be an architectural overview and demo of the unique ways we are infusing these technologies into our visualization tools. We are expecting these developments to transform the way our customers engage and interact with our software.”

Retrocausual

Leverage LeanGPT™ foundation models, shop-floor analytics, and secure knowledge base training to generate valuable documentation, analyses and ideas through a conversational interface.

Sight Machine

Sight Machine Factory CoPilot Democratizes Industrial Data With Generative AI

Using a natural language user interface similar to ChatGPT, Factory CoPilot offers an intuitive, “ask the expert” experience for all manufacturing stakeholders, regardless of data proficiency. In response to a single question, Factory CoPilot can automatically summarize all relevant data and information about production in real-time (e.g., for daily meetings) and generate user-friendly reports, emails, charts and other content (in any language) about the performance of any machine, line or plant across the manufacturing enterprise, based on contextualized data in the Sight Machine platform.

SymphonyAI

Plant Performance Copilot enables users, including plant managers, maintenance, and reliability engineers, to quickly uncover and implement recommended actions to enhance plant performance by using natural language in a chat format rather than querying databases, interpreting dashboards, or accessing knowledge repositories. It interacts across all relevant data sources for critical asset processes, delivering targeted user assistance, recommends actions, and forecasts plant performance through contextual, proactive insights and automated workflows. Leveraging natural language, it accelerates root cause analysis from generated anomalies, including quantified KPI impact of underperforming assets and processes, along with recommended remediations.

Digital Manufacturing Copilot streamlines and strengthens manufacturing operations by seamlessly tying workflow, production, and asset data together to unveil invaluable production process optimization and bottleneck prevention insights. Generative AI adds a more intuitive ability to run what-if scenarios for production scheduling, boost throughput, and improve overall equipment effectiveness (OEE) metrics.

Connected Worker Copilot can quickly and comprehensively scan machine manuals, procedures, knowledge bases, and other sources of data to provide instant, contextual recommendations and information to users in natural language, enabling them to instantly identify and resolve problems without having to conduct time-consuming research or consult more experienced colleagues. Integrated with SymphonyAI Connected Worker, the copilot streamlines inspections, reduces rework, and minimizes resource waste for frontline workers. Natural language access to troubleshooting guides, maintenance manuals, and procedure documentation fosters smooth operations with clear insights into workflow metrics and assists new employees with a simple screen tap.

Vanti

Vanti Introduces Manufacturing COPILOT, where Manufacturing Data Meets Generative AI

Improve insights into your manufacturing processes with Vanti, an AI-powered data wizard, that understands and responds to natural language questions.

Andonix

Meet Andi: The AI Powered Chatbot Revolutionizing Factories

Andonix proudly introduces Andi, the AI-powered manufacturing chatbot designed to bring AI augmentation to factory workers. Andi is an advanced natural language processing solution driven by AI technology, enabling factory workers to engage in human-like conversations and request expert help and support from the chatbot. Andi can assist with tasks such as automatically monitoring machine and process performance, solving problems, and generating action plans, checklists, and work instructions.

Augmentir

Augie is unique among other smart manufacturing assistants. It leverages proprietary fit-for-purpose, pre-trained LLMs and generative AI, coupled with robust security and permissions.

Augie Industrial Assistant 2.0

Enhancements include support for dozens of new content types, addition of patented-pending prompt-enrichment, and superior prioritization, resulting in increased accuracy and actionability.Augie Content Assistant

Automatically convert existing digital content (Word Excel, PDF, etc) into native Augmentir Work instructions, SOPs, OPLs, CILs, Checklists, etc., accelerating deployment. Generate training, checklists, and quizzes from a wide range of source types including images, manuals, free-form tests, etc., to streamline worker training and onboarding.Augie Data Assistant

Augie provides insights from any source of operational data, including standard datasets such as Skills, Standard Work, Safety, and Work Execution, as well as customer-specific datasets generated through Augmentir’s report configurator. Augie eliminates the need for “report writing” and through its conversational interface answers questions, performs math, and generates graphical reports, increasing responsiveness.Augie Extensibility Assistant

Augie increases the productivity of developers building new functions and supporting existing user-defined functions within Augmentir’s extensibility framework. Augmentir’s unique Platform-as-a-Service offering empowers customers and partners to create unique solutions that solve critical business challenges—a capability that no other platform on the market offers.Augie Industrial GenAI-as-a-Service

As an industry first, Augie exposes its GenAI capabilities as APIs within Augmentir’s extensibility framework. This allows companies and partners to create innovative, customized GenAI solutions tailored to business, or industry-specific needs and use cases. Commonly used APIs include: translateText enabling on-the-fly translation of dynamic content, and imageQA, enabling direct comparison or summarization of images, supporting critical applications in Quality, Safety, and Operations.

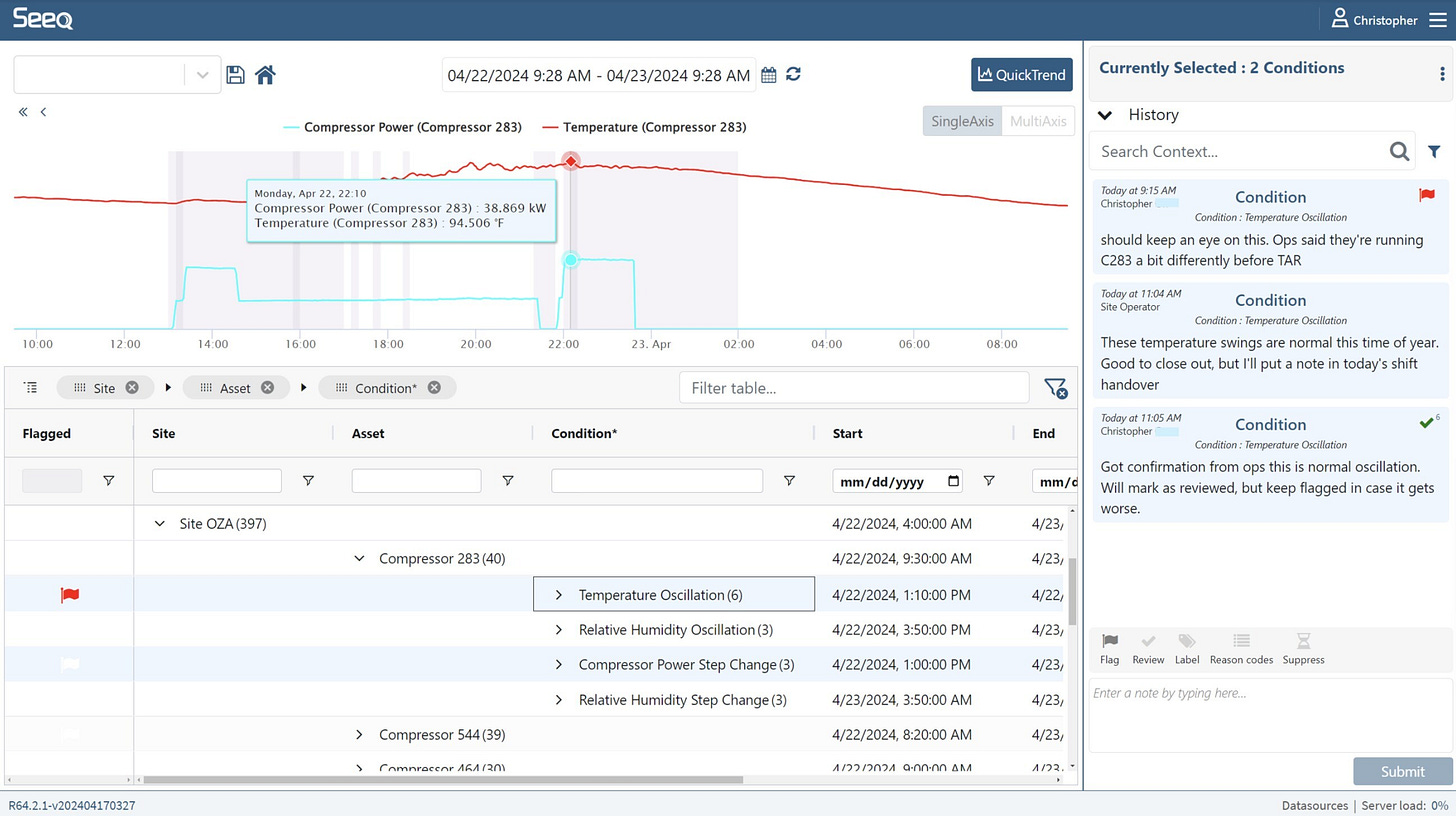

Seeq

Seeq Announces Generative AI Capabilities with Seeq AI Assistant

The Seeq AI Assistant provides real-time assistance to users across the enterprise, empowering them to accelerate mastery of the Seeq platform, build advanced analytics, machine learning, and AI skills and knowledge, and accelerate insights to improve decision making in pursuit of operational excellence and sustainability.

“With the Seeq AI Assistant, we expect to decrease our process experts’ learning curve for advanced analytics and machine learning by 50% or possibly more,” said Brian Scallan, Director of Continuous Improvement at Ascend Performance Materials. “For our extensive user base, this translates into immediate enhancements in process quality and yields, significantly elevating efficiency and value across the organization.”

Seeq Announces Industrial Enterprise Monitoring Capabilities with Seeq Vantage at Conneqt 2024

The Seeq Industrial Enterprise Monitoring Suite provides a comprehensive, automated view into operational performance—past and present. This broader view enables better decision making and continuous improvement across today's complex, industrial ecosystems. The Seeq Industrial Enterprise Monitoring Suite leverages the combined power of the Seeq Industrial Analytics and AI Suite and the context that only teams of experts can provide—all at the scale needed to drive truly impactful results across the operational footprint.

Rockwell Automation

Fiix by Rockwell Automation Announces Industry-Leading GenAI Prescriptive Work Orders

Fiix Asset Risk Predictor's powerful AI can be set up in as little as two weeks and starts predicting asset failures days in advance. With the addition of Fiix Prescriptive Maintenance, it now features GenAI capabilities that transform failure predictions into detailed, actionable work orders for maintenance teams.

Work orders are generated using asset data, completed work orders and trusted maintenance sources. Teams can then review and edit work orders, and instantly push them to any computerized maintenance management system (CMMS) or enterprise asset management (EAM) tool. All data is kept completely private and protected by the highest security standards.

InOrbit

InOrbit Unveils RobOps Copilot for AI-Powered Robot Optimization at Automate 2024

As robotics adoption rapidly accelerates and enters new industries, from supply chain to healthcare, end users must grapple with the complexity of running hundreds of robots across multiple locations, collectively generating vast amounts of data. Now, with RobOps Copilot, actionable insights are available to anyone regardless of technical expertise. Leveraging the latest large language models (LLMs), RobOps Copilot enables users to ask questions in their preferred language, get detailed explanations, refine their analysis, and arrive at key optimization decisions, seamlessly transitioning between their favorite messaging platform for casual queries and a fully integrated experience with chat-driven dashboard explorations.

oee.ai

Generative AI-powered Root-Cause Problem-Solving in Manufacturing

Knowledge collection occurs over an extended period, especially when dealing with a complex loss reason catalog. Capturing multiple instances of each loss reason—potentially from different operators—ensures comprehensive coverage. A detailed catalog enables operators to document more precise troubleshooting advice, which results in even more specific and actionable insights later.

The data is processed through our generative AI module, which transforms it into clear and concise guidance for equipment operators. The AI generates simple, easy-to-understand instructions, often in bullet points or short sentences, with no restriction on the output language. Whether your equipment is operated in the US, Poland, Italy, or Germany, oee.ai provides unified root-cause problem-solving knowledge in any language, for any location.

remberg

How does the remberg AI Copilot work?

Import Master Data: You can import all equipment and asset master data from existing systems, such as (heritage) ERPs, either via our REST API or CSV batch migration

Import Documentation & Files: You then import all relevant files and documentation and associate those with each asset through a bulk upload or REST API

Ask the remberg AI Copilot: Once the data and documentation are in place, you can start interacting with the Copilot asking questions e.g. to significantly reduce the time required to resolve technical issues.

Attention Is All You Need

Several platforms are well positioned for integrating ChatGPT-like functionality but have yet to make any announcements. Ones with notable silence on ChatGPT/LLM capabilities include:

Augury’s Production Health solution “helps you continuously improve your machine performance and processes- transforming the way you work and enabling innovation throughout your organization.”

PTC’s ThingWorx offers workforce efficiency and asset optimization.

GE’s Proficy Historian “collects industrial operations time-series and A&E data at very high speed, stores it efficiently and securely in the cloud or on-prem, distributes it, and allows for fast retrieval and analysis —driving greater business value.”

For LLMs in industrial automation systems read more below!

SEP 25, 2024 Update:

Added Seeq Industrial Enterprise Monitoring Suite updates.

Added Augie by Augmentir updates.

MAY 12, 2024 Update:

Added Fiix by Rockwell Automation's GenAI Prescriptive Work Orders and InOrbit RobOps Copilot™