Speeding up Material Movement Across "Zero Distance"

This week: GE Appliances’ “zero distance” approach, OPPO’s flagship smartphone factory, evolution of AI in engineering, injection molding chat, Robots-to-Goods, New Glenn-2 launch, terraforming robots

Shop Talk

Capturing this week’s zeitgeist

It’s always great to see friends of the publication not just succeeding, but having fun doing it. A perfect example is Azumuta, the operator-centric software scale-up, which just raised €8 million in Series A funding to continue bridging the gap between ambition and technology on the factory floor. With a company name that literally translates from their local Ghent dialect to “that’s how it’s done,” they’re clearly enjoying the process of solving a major industrial challenge.

This is exactly how this publication attracts leading thinkers and surfaces bold ideas: we focus on the innovators, like Azumuta, who are building AI-rich software that operators actually want to use, proving that efficiency and empowering the workforce go hand-in-hand.

If you want to write something fun together respond to this email and we will figure out a format. Congrats Batist and team!

Assembly Line

This week’s Industry 5.0 breakthroughs and frontier technologies of the built world.

How GE Appliances is using new tech to fuel a ‘zero distance’ supply chain

✍️ Author: Philip Neuffer

Technology is at the heart of GE Appliances’ “zero distance” approach. Of the $3 billion it plans to spend in the U.S. over the next half-decade, a large portion will go toward installing new automation and capital equipment at its 11 manufacturing facilities and microfactories.

By leveraging automation technology, the company can now produce many products in less than two labor hours, which is a reduction of at least 50% compared to output 25 years ago, according to Good. By building a system with a real-time data stream, the company has been able to reduce downtime to less than 5% in most of its facilities, according to Good. Previously, that mark hovered between 15% and 20%. To accelerate the movement of goods, the company has automated many of its processes, including using autonomous vehicles to transport components within its plants. Additionally, the company is piloting an automated box truck that can deliver products from a manufacturing facility to a warehouse without human intervention, Good said.

Read more at Supply Chain Dive

GM wants parts makers to pull supply chains from China /Reuters/

Tesla Wants Its American Cars to Be Built Without Any Chinese Parts /WSJ/

How Smartphones Are Made in China

Ever wondered how your smartphone is actually made? Exclusive access to OPPO’s flagship factory in China to see the full process—from microscopic components to final assembly and testing.

Can anything halt the decline of German industry? /FT/

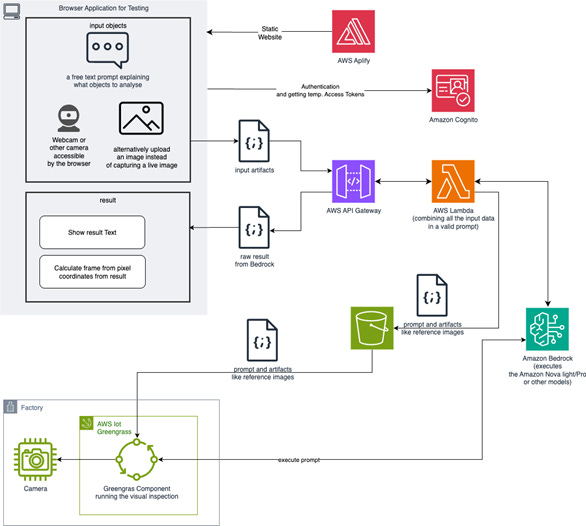

Implement Zero-Training Visual Defect Detection in Manufacturing with Amazon Nova Pro

The key advantage of using an LLM such as Amazon Nova Pro over a traditional ML model is that it does not require building training datasets, labelling, and training machine learning models to detect defects. Additionally, this approach is flexible: CV approaches either require vast data sets or retraining when there are small variations of the product or the surrounding setup, such as different camera models or lighting variances. The LLM-based approach copes with such changes without any modifications or requires a simple adaptation of the input prompt to the LLM. This makes the use of LLMs more viable for production uses, including products that have significant variations or frequent changes in the production set-up.

The LLM identifies missing components, surface defects, misalignments, scratches, and cracks without specialized training – a capability previously unattainable with a traditional ML model. As we demonstrate, it is even possible to classify different types of defects without any training data.

Read more at AWS Blogs

Unlocking Machine Intelligence: Industry.AI and Tresata to Deliver the World’s Largest AI-Ready Data for Industry and Machines /Tresata/

Egocentric-10K is state-of-the-art in hand visibility and active manipulation density compared to previous in-the-wild egocentric datasets /HuggingFace/

Manufacturing-driven AI: synthetic image generation for automated fiber orientation analysis in reinforced polymers /Advanced Manufacturing Technology/

MathWorks and the evolution of AI in engineering

Richard Rovner, Vice President of Marketing at MathWorks, explores the fascinating evolution of AI in engineering by tracing the technology’s journey from its early days in the 1980s, through transformative milestones like deep learning and code generation, all the way to today’s AI-driven design tools and copilots.

IM-Chat: A multi-agent LLM framework integrating tool-calling and diffusion modeling for knowledge transfer in injection molding industry

The injection molding industry faces critical challenges in preserving and transferring field knowledge, particularly as experienced workers retire and multilingual barriers hinder effective communication. This study introduces IM-Chat, a multi-agent framework based on large language models (LLMs), designed to facilitate knowledge transfer in injection molding. IM-Chat integrates both limited documented knowledge (e.g., troubleshooting tables, manuals) and extensive field data modeled through a data-driven process condition generator that infers optimal manufacturing settings from environmental inputs such as temperature and humidity, enabling robust and context-aware task resolution. By adopting a retrieval-augmented generation (RAG) strategy and tool-calling agents within a modular architecture, IM-Chat ensures adaptability without the need for fine-tuning. Overall, these findings demonstrate the viability of multi-agent LLM systems for industrial knowledge workflows and establish IM-Chat as a scalable and generalizable approach to AI-assisted decision support in manufacturing.

Read more at Journal of Manufacturing Systems

Integrating Agentic AI into Manufacturing Control Systems /Micro.ai/

If you found value in this issue, please forward it to a friend, share it on social media, or post it in your organization’s chat.

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

The Dawn of Robots-to-Goods: Locus Robotics Ships its First Array Units to DHL

This week marks one of the most exciting milestones in Locus Robotics’ history — their first Locus Array units arrived at a DHL facility in Columbus, OH. Sally Miller, Global Chief Information Officer at DHL, said, “At DHL Supply Chain, we don’t just test ideas — we scale innovation globally. Thousands of Locus Origin robots are already transforming our operations worldwide. Now, we’re proud to be the first to deploy Locus Array. This marks the next chapter in autonomous picking and replenishment, and together with Locus, we’re ready to make it a success story.”

This moment has been years in the making. It’s been a multi-year journey of reimagining what warehouse automation could be. Along the way, we became the leader in Person-to-Goods (P2G) solutions and are now defining an entirely new category of automation: Robots-to-Goods (R2G). R2G changes this equation. With Locus Array, robots autonomously pick, move, and replenish inventory to perform tasks that used to require multiple human touches. Locus Array represents the convergence of Agentic AI (digital reasoning and orchestration) and Physical AI (real-world perception and execution). Together, they create systems that sense, decide, and act as one to seamlessly connect digital intelligence with physical action.

Read more at Locus Robotics

Track how far along Tesla’s Optimus program is /Phil Trubey on X/

New Glenn Launches NASA’s ESCAPADE, Lands Fully Reusable Booster

The New Glenn orbital launch vehicle successfully completed its second mission, deploying NASA’s Escape and Plasma Acceleration and Dynamics Explorers (ESCAPADE) twin-spacecraft into the designated loiter orbit, and landing the fully reusable first stage on Jacklyn in the Atlantic Ocean. New Glenn’s seven BE-4 engines ignited on Thursday, November 13, 2025, at 3:55:01 PM EST / 20:55:01 UTC from Launch Complex 36 at Cape Canaveral Space Force Station.

The ESCAPADE spacecraft will begin their journey to Mars once the planets have returned to the ideal alignment in fall 2026. ESCAPADE will use two identical spacecraft to investigate how the solar wind interacts with Mars’ magnetic environment and how this interaction drives the planet’s atmospheric escape. In addition to deploying the NASA spacecraft, the Viasat HaloNet demonstration onboard New Glenn’s second stage successfully executed the first flight test of Viasat’s telemetry data relay service for NASA’s Communications Services Project.

Read more at Blue Origin

Business Transactions

This week’s top funding events, acquisitions, and partnerships across industrial value chains.

What Should PTC Build or Buy After ThingWorx and Kepware? /Beyond PLM/

🇺🇸 $60M Raise Accelerates Carbon in the Advanced Manufacturing Race

Carbon, Inc., a Silicon Valley–based additive manufacturing company enabling large-scale production across a wide range of industries, announced it has raised $60 million in new funding. The round was headlined by current investors Sequoia Capital, Silver Lake, adidas, Baillie Gifford, Madrone, and Northgate. With increasing production volumes, improved process efficiencies, an exciting roadmap of new products, and deepening customer and partner relationships, Carbon is approaching an important milestone: achieving cash-flow positive operations. This round is designed to scale capacity and cement Carbon’s footing as the additive manufacturing leader with a sustainable business model.

Read more at PR Newswire

Physics-Informed Hybrid Deep Learning-Driven Sintering Simulation for Next-Generation Metal Additive Manufacturing /Additive Manufacturing/

🇮🇸 Euler Closes €2 Million Seed Round to Scale AI Fault Detection in 3D Printing /3DPI/

🇺🇸 How one founder plans to save cities from flooding with terraforming robots

✍️ Author: Tim De Chant

Terranova is building robots that will inject a slurry of wood waste into the ground, slowly lifting the land to eliminate historical subsidence and, hopefully, prevent those parts of the city from flooding. Terranova says it can protect San Rafael and other cities like it for a fraction of the cost. In San Rafael’s case, the startup has quoted $92 million to lift 240 acres four feet.

The company recently raised $7 million in a seed round led by Congruent Ventures and Outlander with participation from GoAhead Ventures, Gothams, and Ponderosa, TechCrunch has exclusively learned. The oversubscribed round values the company at $25.1 million.

Read more at TechCrunch

🇨🇳 Partner Robotics raises Series A funding to deploy robots on construction sites worldwide /PR Newswire/

🇺🇸 Litmus Secures Additional Investment Led by Insight Partners to Accelerate Industrial AI

Litmus, the leading Industrial Edge Data Platform, announced additional strategic funding from Insight Partners and Munich Re Ventures via HSB Fund II. The capital infusion will advance Litmus’ mission to make industrial data instantly accessible, contextualized, and AI-ready across global manufacturing enterprises.

Litmus has become the data foundation for the world’s largest manufacturers, connecting machines, systems, and cloud environments through the broadest native OT connectivity in the industry—with over 250 out-of-the-box connectors. Its long-standing collaborations with Microsoft Azure, Google Cloud, AWS, and Dell Technologies expanded in 2025 with new partnerships with Oracle Cloud and Databricks, creating one of the most connected edge-to-cloud ecosystem in industrial data.

Read more at Litmus

Want more? Check out the bonus reads below 👇