White-knuckle Microfactories

This week: Robocraftsman hit a bridge, autonomous mobile robots value, white bone programs, low-cost mini fabs, rare earths production, world’s largest 3D printing factory, and Amca

Shop Talk

Capturing this week's zeitgeist

How it Started vs How It's Going

We have a fully done one, that’s going to get shipped out next week...

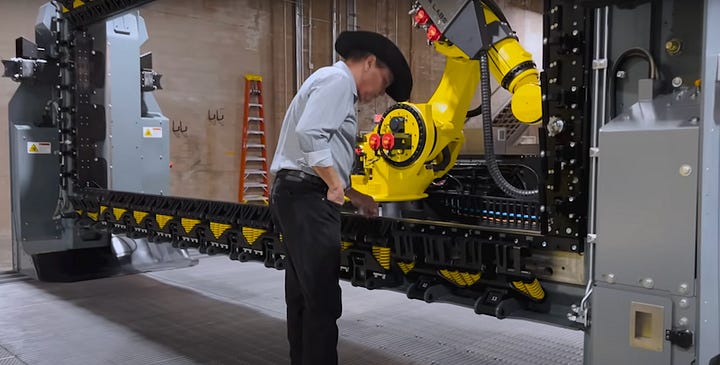

Manufacturing equipment delivery involves much more than just production—the entire journey from order to operation is critical for customer value. As highlighted in Novarc's approach with their Spool Welding Robot, while manufacturing lead times matter, the comprehensive process includes transport (see Machina Labs’ oopsie above), planning, installation, and training phases. The planning stage establishes project requirements and site preparation; installation requires technical expertise and testing; and operator training ensures the equipment delivers immediate value. Without this complete onboarding process, even perfectly manufactured equipment fails to provide return on investment. Manufacturers who recognize that delivery timelines, installation logistics, and proper training are as important as the equipment itself can ensure customers experience minimal downtime and maximum productivity from day one.

Don't miss out on hundreds of industrial innovations we couldn't fit in this week's digest. Unlock the complete collection by upgrading to paid — your competitive advantage is just one click away 👇

Assembly Line

This week's most influential Industry 4.0 media.

ANYbotics has 400 employees, and 200 of them are human.

ANYbotics clients’ think about how to run their large plants and installations optimally. They want to minimize downtime, which costs them hundreds of thousands per day. They also want to minimize surprises, so their employees, usually highly sought-after and skilled production engineers, inspect parts of the plant by performing inspection rounds multiple times a day. The plant owners use sensors and IoT as much as technology permits, but they still need humans for a majority of inspection tasks. In some environments, think high voltage, you need to shut down parts of the installation for humans to pass. Other environments are dangerous or at least uncomfortable for humans, imagine gas leaks or high temperatures. We complement human capabilities with robotic ones to ensure plant safety and highly reliable data collection.

Switzerland excels in robotics, and the Robotics Systems Lab at ETH Zurich is a talent factory for founders. What makes it successful in creating spin-offs?

A general advantage of Switzerland as a country in robotics is its broad mechanical engineering industry. We have two centuries of tradition in this field, many people who understand how to build things and are passionate about it, and an apprenticeship system that produces excellent mechatronics specialists. It helps that large companies such as Siemens and ABB have R&D centers in Switzerland. Both ETH Zurich and EPFL have outstanding professorships in Computer Science and AI, which is also crucial for robotics. Finally, a generation of Professors like Roland Siegwart and Rafaello D’Andrea have firmly anchored the spirit of entrepreneurship in students’ minds. Also, the pioneering drone startup Flyability in Lausanne has inspired many founders and served as an example of what is possible. For me, robotics is a perfect field because you can create many exciting new things. I wouldn’t want to spend my life trying to improve the efficiency of a combustion engine by another percent.

Read more at verve.vc

Head, Shoulders, Knees & Toes:

👋 Meet the robots that keep DHL running /AutomatedWarehouse/

🤖 Humanoid Robotics: Game Changer or Hype? /The Industrial AI Podcast/

🦾 The $40 Billion Startup Mystery Shaking Up Silicon Valley /WSJ/ but are they exaggerating work with BMW? /Fortune/

🦿Elon Musk says he plans to send his humanoid robots to Mars by 2026 /Global News/

🍲 MULTIVAC UK invited the BBC into their Innovation Centre in Swindon

🍖 Beef Is Expensive. Meatpackers Are Scraping Every Morsel From Bones by embracing “white bone” programs, aiming to pick every carcass clean as they move down processing lines. /WSJ/

🐟 Sonofai revolutionizes frozen tuna inspection with new device incorporating Fujitsu AI tech /Fujitsu/

Coming Soon: Low-Cost Mini Fabs

✍️ Author: Alan Patterson

Two companies are starting sales of entire chipmaking facilities that will cost as little as $30 million and occupy a space that is tiny compared to a typical multibillion-dollar chip fab. The mini fabs will make lagging-edge power semiconductors and flexible chips for retail labeling and consumer electronics. The facilities can be built in locations once thought impractical for chip production, the company CEOs told EE Times in interviews.

“We can look at building a new line out in as little as 12 to 14 months versus the typical three to five years,” noted Pragmatic CEO David Moore. “Because we’re using fewer steps and more cost-effective materials, we’re able to get to a more optimized cost overall for the product.”

Across the Atlantic in the U.S., Nanotronics has demonstrated that its “Cubefabs” can make devices that outperform some state-of-the-art power semiconductors. “We’re achieving higher kilovolts while maintaining the thermal properties,” Nanotronics CEO Matthew Putman told EE Times. “We’re now making these chips and collaborating with semiconductor companies to scale their production.”

Read more at EE Times

Apple, Nvidia Score Relief From US Tariffs With Exemptions /Bloomberg/ but not the machines used to make semiconductors /White House/

Apple Supplier Luxshare to Maintain Vietnam Production Hub to Support U.S. Market /WSJ/

Apple, Michigan State University to jointly open manufacturing academy /Manufacturing Dive/

CTL-YOLO: A Surface Defect Detection Algorithm for Lightweight Hot-Rolled Strip Steel Under Complex Backgrounds

Currently, in the domain of surface defect detection on hot-rolled strip steel, detecting small-target defects under complex background conditions and effectively balancing computational efficiency with detection accuracy presents a significant challenge. This study proposes CTL-YOLO based on YOLO11, aimed at efficiently and accurately detecting blemishes on the surface of hot-rolled strip steel in industrial applications. Firstly, the CGRCCFPN feature integration network is proposed to achieve multi-scale global feature fusion while preserving detailed information. Secondly, the TVADH Detection Head is proposed to identify defects under complex textured backgrounds. Finally, the LAMP algorithm is used to further compress the network. The proposed algorithm demonstrates excellent performance on the public dataset NEU-DET, achieving a mAP50 of 77.6%, representing a 3.2 percentage point enhancement compared to the baseline algorithm. The GFLOPs is reduced to 2.0, a 68.3% decrease compared to the baseline, and the Params are reduced to 0.40, showing an 84.5% reduction. Additionally, it exhibits strong generalization capabilities on the public dataset GC10-DET. The algorithm can effectively improve detection accuracy while maintaining a lightweight design.

Read more at machines

Optimization of process parameters in metal injection molding for turbine blade using response surface methodology /The International Journal of Advanced Manufacturing Technology/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

Solvay advances European rare earths production through capacity expansion

Solvay has officially inaugurated its rare earths production line for permanent magnets at the La Rochelle facility, marking a significant milestone in the Group’s commitment to meeting Europe’s strategic goals. This expansion enables Solvay to start delivering rare earth materials for permanent magnets, reinforcing its position as a global leader in the rare earths market.

The investment in France enhances an established facility, the biggest plant outside China capable of separating all rare earth materials. With its historical and pioneering process leadership, Solvay is committed to leveraging its expertise and scale to support green technologies and contribute to Europe's autonomy in rare earths production, aligning with the Clean Industrial Deal.

Read more at Solvay

Extracting hydrogen and critical metals from nuisance seaweed /c&en/

China’s Rare Earths Riposte /The Wire China/

Haddy Launches the World’s Largest 3D Printing Factory

Haddy, the pioneering company redefining large-scale digital manufacturing, officially opens the doors to its new microfactory – which becomes the largest and most powerful 3D printing facility in the world. With this launch and in light of recent trade and tariff developments, the facility becomes a symbol of the next era of American manufacturing.

The AI-powered factory has 16 times the production capacity of its nearest 3D printing competitor and shows the future of manufacturing that is fast, scalable, and radically adaptive. Designed to prove that the U.S. can lead again in how things are made, the facility combines robotics, AI-driven production, and fully recyclable materials to deliver industrial-grade products faster, cleaner, and closer to where they’re needed.

Read more at Business Wire

HP showcases additive manufacturing updates at RAPID + TCT 2025 /Engineering.com/

Development of an Open-Source 3D-Printed Material Synthesis Robot FLUID: Hardware and Software Blueprints for Accessible Automation in Materials Science /ACS Applied Engineering Materials/

First Supercritical CO2 Circuit Breaker Debuts

✍️ Author: Emily Waltz

Researchers this month will begin testing a high-voltage circuit breaker that can quench an arc and clear a fault with supercritical carbon dioxide fluid. The first-of-its-kind device could replace conventional high-voltage breakers, which use the potent greenhouse gas sulfur hexafluoride, or SF6. Such equipment is scattered widely throughout power grids as a way to stop the flow of electrical current in an emergency.

If successful, the invention, developed by researchers at the Georgia Institute of Technology, could have a big impact on greenhouse gas emissions. Hundreds of thousands of circuit breakers dot power grids globally, and nearly all of the high voltage ones are insulated with SF6.

Read more at IEEE Spectrum

World’s first highly flexible and ultra-sensitive ammonia sensor technology /Tech Explorist/

Smart Ball technology detects the smallest leaks in underground pipelines /Smart Water/

FaradaIC Sensors raises €4.5M for electrochemical gas detection tech /Tech EU/

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇺🇸 Base Power Raises $200M Series B to Reinforce the Texas Power Grid, Accelerate National Expansion, and Build American Manufacturing Capabilities

Base Power announced it has raised $200 million in Series B funding, co-led by Addition, Andreessen Horowitz, Lightspeed Venture Partners and Valor Equity Partners with participation from existing investors Thrive Capital, Altimeter, Terrain, Trust and others.

With the new funding, Base Power will continue its rapid growth, bringing affordable and reliable energy to more homes across Texas while preparing for national expansion with its battery-powered home energy service. This investment will go toward building the first Base factory in Texas to meet growing demand while ensuring greater resilience, cost efficiency, and control as the company scales.

Read more at Business Wire

🇺🇸 Rescale Secures $115 Million to Accelerate Innovation with AI-Driven Digital Engineering

Rescale, the digital engineering platform built for the future of innovation and scientific discovery, announced a $115 million Series D with participation from Applied Ventures, Atika Capital, Foxconn, Hanwha Asset Management Deeptech Venture Fund, Hitachi Ventures, NEC Orchestrating Future Fund, NVIDIA, Prosperity7, SineWave Ventures, Translink Capital, University of Michigan, and Y Combinator bringing total funding raised to over $260 million.

Rescale's new funding will expedite growth of its comprehensive digital engineering platform for advanced computing, intelligent data, and applied AI. To support the increasing demand for its platform, Rescale is accelerating the delivery of its roadmap including:

Expanding the range of new workflows and computing technologies available to its customers; growing its market-leading library of over 1,250 applications and global network of more than 500 cloud datacenters with its technology partners such as AMD, Amazon Web Services, Arm, Intel, Microsoft Azure, NVIDIA, and Oracle Cloud Infrastructure.

Establishing unified data fabric and digital thread capability for all modeling and simulation workflows, along with AI-native search, tagging, and automation; while expanding on robust enterprise security and compliance offerings, including additional authorizations for government and defense customers.

Empowering industrial enterprises for the next era of AI-powered engineering, enabling organizations to democratize and automate the use of industry-leading AI Physics tools and libraries, resulting in over 1000x speed improvements in design validation.

Read more at PR Newswire

🇺🇸 Amca, a legacy aerospace business built for the future, launches with $76M to acquire specialized suppliers and develop new products

The Advanced Manufacturing Company of America (Amca), headquartered in El Segundo, CA, has launched with $76.5 million in initial funding and a vision to renew the entrepreneurial spirit and engineering legacy of the aerospace and defense industry's golden age. Backed by Caffeinated Capital, Founders Fund, Lux Capital, Andreessen Horowitz, and others, Amca has acquired its first supplier—Electro-Mech Components, Inc. in South El Monte, CA—and counts Boeing among its customers for its line of human-machine interface products.

Amca's founders are Jai Malik, a serial investor and entrepreneur focused on aerospace and defense, and Eli Giovanetti, who was previously a senior production and engineering leader at SpaceX. Amca is focused on designing and manufacturing the products that sit between standardized parts and full systems—products like sensors, power units, and flight-control computers that are highly critical to system function and performance.

Read more at PR Newswire

🇺🇸 Optilogic Closes $40M Series B to Accelerate Development of Breakthrough Optimization and Decision-Making Platform

Supply chain design software innovator Optilogic closed its $40 million Series B round, led by NewRoad Capital Partners, an operator-led investment firm focused on high-growth supply chain and logistics, retail, and marketing technology companies, and joined by MK Capital and Moore Strategic Ventures. The funding will empower Optilogic to intensify development of its industry-first optimization and decision-making platform which will transform how global businesses reimagine supply chains. The supply chain design leader will also bring on additional vertical industry and supply chain experts to optimize customer success.

Read more at PR Newswire