What’s Your Dream Factory?

This week: High-risk, high-reward manufacturing technology and Garage CNC, automated picking, 3D printing quality control, CATL Bedrock EV Chassis, and tasty mergers and unsolicited bids.

Shop Talk

Capturing this week's zeitgeist

Some people dream of sugar plums dancing, but manufacturing leaders dream of fully optimized production lines, zero-defect quality, and real-time visibility across their entire operation. The reality is that today's smart factories are getting closer to making these dreams come true. With advances in industrial IoT, machine learning, and digital twins, what once seemed like fantastical visions are becoming achievable goals. So, I've been dreaming too - about how to make Exponential Industry your go-to radar for spotting breakthrough industrial technologies and quantifying their bottom-line impact before anyone else.

Assembly Line

This week's most influential Industry 4.0 media.

🧵 High-Risk, High-Reward: Investing in Game-Changing Plastics Extrusion Technology

✍️ Author: Rehana Begg

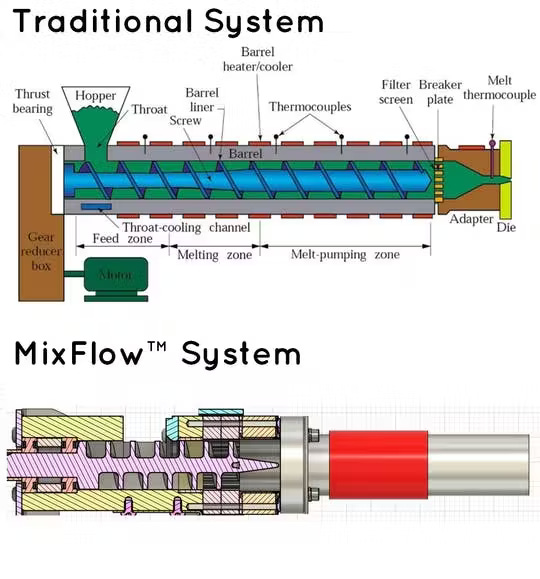

ReDeTec, a Toronto-based small business, has developed MixFlow, a filament extrusion system that promises a new way to melt plastics. Whereas traditional systems churn a screw through molten plastic, ReDeTec’s novel filament extrusion design separates the drive section and melt section with a thermal isolator, allowing independent control of temperature and pressure, explained Meij, CEO of BM3 Ventures Ltd., and an early-stage investor in the plastics extrusion system.

ReDeTec’s extrusion technology is game changing because it uses 50% less energy than competing systems and offers higher throughput and more automation, Meij said during a call to invite Machine Design to visit ReDeTec’s R&D facility in Toronto. “The solution has disruptive potential,” he touted.

Plastics extrusion is a high-efficiency, low-volume manufacturing process where raw plastic material is melted and shaped into a continuous profile by forcing it through an extrusion die. The process is widely used to produce continuous components or products, such as pipes, tubing, fencing, deck railings, window frames, plastic films, sheets, thermoplastic coatings and wire insulation. Injection molding, by contrast, forms a part by injecting molten material into a mold. The process can handle a broader range of materials required to produce discrete products, such as automotive parts or bottle caps, and is associated with greater precision, complexity and tolerances than plastic extrusion processes.

Read more at Machine Design

Small machine shop: Ending 2024 (Xometry Results : Growth : Syil X7)

📦 MHI's Automated Picking Solution Utilizing ΣSynX Fully Implemented at Kirin Group's Ebina Logistics Center, the First Such System in Japan

The automated picking solution utilizing ΣSynX, developed by Mitsubishi Heavy Industries, introduces automation and intelligence for the picking work that up to now has been performed manually by workers, who have also been responsible for considering how to improve efficiency in their picking operations. The system utilizes a proprietary optimization engine and integrated control system to efficiently coordinate multiple automated guided forklifts (AGFs), automated guided vehicles (AGVs), and palletizers in order to reduce the number of picking and transfer operations, optimize the picking process, and improve throughput (processing capacity).

MHI Group continues to collaborate with Kirin Group on joint demonstration projects for the automation of inbound and outbound processes at beverage warehouses using a new type of unmanned forklift equipped with ΣSynX, and automation solutions for the loading and unloading of trucks.

Read more at MHI News

🎁 Hoping the gifts arrived:

Ocado warehouse tech issues leave London customers with Christmas delivery shortages [RTIH] while American Airlines delays pile up after technical issue [WSJ]

Boston Dynamics discusses Stretch deployment at Otto Group [AutomatedWarehouse]

Ambi Robotics founder sees ‘huge opportunities’ in new markets [RoboticsAndAutomationNews.com]

📐 High-Precision Shaft Inspection with 3D Metrology

🖨️ The Future of Manufacturing Is on Display at Prof. Ping Guo’s Northwestern Lab

Northwestern University’s Ping Guo is at the forefront of advanced manufacturing research, exploring innovative technologies that are shaping the future of additive manufacturing (AM) and beyond.

At the heart of many 3D printing challenges is quality control, a domain where Guo’s team has developed game-changing solutions. Leveraging photometric stereo and deep learning algorithms, the lab has created a metrology system capable of detecting surfaces defects additively manufactured parts. This system uses multi-modal imaging and computer vision to provide real-time 3D geometry and surface texture analysis, all within a scalable framework.

Another groundbreaking area of research in Guo’s lab is the production of high-quality metal powders for AM. By employing ultrasonic vibration machining, the team has demonstrated a novel method for generating uniform, micron-sized powders with tight dimensional tolerances. This solid-state process avoids the traditional atomization methods that require high energy inputs and often result in material waste.

Read more at 3DPrint.com

🔎 Talk later, heading to print club:

Keep rolling: Inside DB ESG's additive manufacturing lab [TCT]

How to build (and rebuild) with glass [MIT News]

A closer look at Mechnano's carbon nanotube technology [TCT]

The unique challenges for quality assurance in additive manufacturing [TCT]

The Future of Financing CapEx Equipment

SemiKong: Curating, Training, and Evaluating A Semiconductor Industry-Specific Large Language Model

✍️ Authors: Christopher Nguyen, William Nguyen, Atsushi Suzuki

🏢 Organizations: Aitomatic, FPT Software, Tokyo Electron

Large Language Models (LLMs) have demonstrated the potential to address some issues within the semiconductor industry. However, they are often general-purpose models that lack the specialized knowledge needed to tackle the unique challenges of this sector, such as the intricate physics and chemistry of semiconductor devices and processes. SemiKong, the first industry-specific LLM for the semiconductor domain, provides a foundation that can be used to develop tailored proprietary models. With SemiKong 1.0, we aim to develop a foundational model capable of understanding etching problems at an expert level. Our key contributions include (a) curating a comprehensive corpus of semiconductor-related texts, (b) creating a foundational model with in-depth semiconductor knowledge, and (c) introducing a framework for integrating expert knowledge, thereby advancing the evaluation process of domain-specific AI models. Through fine-tuning a pre-trained LLM using our curated dataset, we have shown that SemiKong outperforms larger, general-purpose LLMs in various semiconductor manufacturing and design tasks. Our extensive experiments underscore the importance of developing domain-specific LLMs as a foundation for company- or tool-specific proprietary models, paving the way for further research and applications in the semiconductor domain.

Read more at arXiv

🈸 Large language models are still getting better:

DeepSeek-V3 Technical Report [deepseek-ai]

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🚙 CATL Launches the Bedrock Chassis That Withstands 120 km/h Impact Without Catching Fire or Exploding

CATL officially launched the CATL Bedrock Chassis, the world’s first ultra-safe skateboard chassis. With its outstanding performance of withstanding 120 km/h frontal impact without catching fire or exploding, CATL’s Bedrock Chassis sets a new standard for intelligent chassis safety, providing comprehensive protection across all scenarios and speed ranges.

With the battery-centered design, CATL’s Bedrock Chassis utilizes Cell-to-Chassis integration technology, which directly integrates the battery cells into the chassis, allowing for a shared structural design between them. And based on the decoupling of the chassis from the upper body, the Bedrock Chassis is capable of absorbing 85% of the vehicle’s collision energy (compared to around 60% absorbed by traditional chassis).

Read more at PR Newswire

🔋 Make batteries go round:

CATL plans Hong Kong listing [SCMP]

Boosting yield with conveyors [ASSEMBLY]

LGES Announces Availability of Advanced Battery Management System Solutions for Automotive [LGES]

New Electrochemical Impedance Spectroscopy System Monitors EV Batteries [ASSEMBLY]

Olympian Motors and NVIDIA Pioneer the First AI-Powered EV Platforms [Olympian Motors]

💧 The world’s first industrial-scale plant for green steel promises a cleaner future

✍️ Author: Douglas Main

A handful of groups and companies are now making serious progress toward low- or zero-emission steel. Among them, the Swedish company Stegra stands out. (Originally named H2 Green Steel, the company renamed itself Stegra—which means “to elevate” in Swedish—in September.) Stegra says it is on track to begin production in 2026, initially producing 2.5 million metric tons per year and eventually making 4.5 million metric tons.

This process of using hydrogen to make iron—and subsequently steel—has already been used at pilot plants by Midrex, an American company from which Stegra is purchasing the equipment. But Stegra will have to show that it will work in a far larger plant. Stegra’s process is very similar to the standard direct reduction technique, except that since it uses only hydrogen, it needs a higher temperature. It’s not the only possible way to make steel with a negligible carbon footprint, but it’s the only method on the verge of being used at an industrial scale.

Stegra’s business model is made possible in part by the unique economic conditions within the European Union. In December 2022, the European Parliament approved a tariff on imported carbon-intensive products such as steel, known as the Carbon Border Adjustment Mechanism (CBAM). As of 2024, this law requires those who import iron, steel, and other commodities to report the materials’ associated carbon emissions. Starting in 2026, companies will have to begin paying fees designed to be proportional to the materials’ carbon footprint. Some companies are already betting that it will be enough to make Stegra’s 30% premium worthwhile.

Read more at MIT Technology Review

Eni fires up €100mn supercomputer in race to find oil and gas reservoirs

✍️ Author: Malcolm Moore

Built at a cost of more than €100mn, Eni’s new machine, HPC6, will be switched on in the small Italian town of Ferrera Erbognone, population 1,140. It contains almost 14,000 AMD graphics processing units: high-powered chips used to perform complex calculations and run artificial intelligence processes.

“We have used the supercomputer in all of our latest discoveries,” Lorenzo Fiorillo, the head of Eni’s research and digital department, added, saying that extreme computing power helped Eni navigate the so-called pre-salt layer, a series of geological formations beneath thick layers of salt on both sides of the south Atlantic. “Our algorithms can create clear images of where the oil is and how big it is,” he said.

Read more at Financial Times

🛢️ Still running on petroleum and coal:

Gas pipeline defect detection based on improved deep learning approach [Expert Systems with Applications]

Inside an American Rare-Earth Boomtown [IEEE]

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

PFN Raises Total of 19 Billion Yen in Latest Round

🔖 Topics: Funding Event

Preferred Networks, Inc. (PFN) announced that it has raised a total of 19 billion yen in the first close of the latest equity financing round led by SBI Group combined with debt financing from financial institutions. PFN intends to use the new capital for talent acquisition efforts as well as for development, production and sales of the low-power AI processors in its MN-Core™ series, especially MN-Core L1000, the generative AI inference processor currently under development. The new capital will also be used for enhancing its Japan-made generative AI foundation model PLaMo™, development of solutions and products in a range of domains powered by these technologies, and the large-scale computing infrastructure that supports them.

Read more at PFN News

Xerox to Acquire Lexmark

Xerox Holdings Corporation (NASDAQ: XRX) announced it has agreed to acquire Lexmark International, Inc., from Ninestar Corporation, PAG Asia Capital, and Shanghai Shouda Investment Centre in a deal valued at $1.5 billion, inclusive of assumed liabilities. This acquisition will strengthen the Xerox core print portfolio and build a broader global print and managed print services business better suited to meet the evolving needs of clients in the hybrid workplace.

Read more at Xerox News

Honda, Nissan aim to merge by 2026 in historic pivot

Honda and Nissan are in talks to merge by 2026, a historic pivot for Japan’s auto industry that underlines the threat Chinese EV makers now pose to the world’s long-dominant legacy car makers. The tie-up would create the world’s third-largest automotive group by vehicle sales after Toyota and Volkswagen, though some cast doubt.

Taiwan’s Foxconn, seeking to expand its nascent EV contract manufacturing business, approached Nissan about a bid but the Japanese company rejected it, sources have told Reuters. Foxconn decided to pause the approach after it sent a delegation to meet with Renault in France.

Read more at Reuters

Japan's Nidec takes aim at Makino Milling with $1.6 bln unsolicited bid

Japanese manufacturing giant Nidec plans to launch a 257 billion yen ($1.6 billion) bid for Makino Milling Machine, a surprise unsolicited takeover offer in a country better known for agreed deals. Nidec said Makino’s board had not agreed to the 11,000 yen per share offer, a 42% premium to Thursday’s closing share price, as it had not proposed the bid before announcing it. The world’s top manufacturer of precision motors said it plans to clear regulatory processes by early April and launch the tender offer on April 4, even without Makino’s consent.

A reform push by the Tokyo exchange has also sparked a slew of share buybacks, unwindings of cross-shareholdings and management buyouts. Nidec last year acquired Takisawa Machine Tool after making a 16.6 billion yen unsolicited takeover offer. Nagamori told the Nikkei newspaper this month that Nidec was on the hunt for a purchase as big as 1 trillion yen and was eyeing three potential targets in Europe and the United States.

Read more at Reuters

German eVTOL maker Lilium finds investor in miraculous Christmas deal

Last month, the German flying taxi unicorn Lilium was said to be under a major financial crisis. Its main subsidiaries were reported to have filed for bankruptcy. In a recent move, the company laid off 1000 employees and ceased operations. Now, the company has signed an asset purchase agreement with Mobile Uplift Corporation GmbH, a company set up by an experienced consortium of investors from Europe and North America. Mobile Uplift Corporation GmbH intends to acquire the operating assets of the subsidiaries – Lilium GmbH and Lilium eAircraft GmbH. Lilium expects that the Agreement positions its subsidiaries to obtain sufficient funding to restart their business operations.

Read more at TFN