Don't Wait on TIME, Find Innovations Here First

TIME's Best Inventions of 2024 has dropped with many familiar industrial innovations. Exponential Industry revisits these developments and what's next to come.

Industrial technology development is high-stakes and being first isn't just about invention—it's about the long-term competitive advantage of nations. TIME Magazine recently unveiled its "The Best Inventions of 2024" issue, with a familiar sense of déjà vu for long-time Exponential Industry readers. Many of these breakthrough products have been quietly gestating in labs, startups, and industrial facilities for years, leaving telltale signs for those who knew where to look.

For seasoned technology venture capitalists and scouts, identifying tomorrow's money-making innovations is less about crystal balls and more about connecting subtle dots across the industrial landscape. It's about recognizing when technological leaps occur in how things are mined (horizontal drilling and fracking), refined (autonomous control), manufactured (megacasting), assembled (humanoids), or transported (autonomous forklifts) to name a few.

When I first started tracking many of the technologies featured in TIME's latest list, they were little more than promising funding announcements (3 identified this way), early-stage prototypes (5), or commercial agreements (2) scattered across thousands of sources. Their alignment with fundamental market needs and timing with supporting technological ecosystems separated them from countless other innovations.

TIME’s list of 200 groundbreaking inventions (including 14 industrial technology products within our coverage universe) including battery manufacture (2), additive manufacturing (1), humanoids (2), textiles (2), agriculture (1), energy (3), and transportation (3). TIME picked the best inventions based on several key factors including originality, efficacy, ambition, and impact.

Let’s look back at the first signals we picked up for each of the fourteen and where other competing technologies challenge the status quo.

Battery Technology

The transition to a sustainable future hinges critically on our ability to store clean energy effectively and affordably. Battery technology acts as the linchpin in this transformation, enabling everything from the widespread adoption of electric vehicles to the reliable storage of intermittent solar and wind power. As we race to decarbonize our economy, advanced batteries promise to solve one of renewable energy's biggest challenges: its variability. By allowing us to capture energy when the sun shines and wind blows, and use it when needed, batteries bridge the gap between clean energy generation and on-demand consumption.

TIME captured two battery production technologies:

AM Batteries’ pioneering lithium-ion dry coating method cuts the drying and solvent recovery steps, creating a more energy-efficient electrode manufacturing process eliminating the need for heat, dry time, or solvents.

Sakuu's Kavian platform for 3D printing electrodes stands out for its dry-process technology and ability to produce electro-chemistries that consume less energy, produce less waste, and produce more capable products.

AM Batteries first came onto our radar in October 2022 with an investment by Toyota subsequent Series B in December of 2023. Sakuu coverage was initiated in November 2022 following a mention in TCT Magazine and has appeared in four digests since then. An emerging competitor to lithium-ion is sodium-ion being scaled up by the likes of UNIGRID, Peak Energy, and Natron Energy (WSJ).

Additive Manufacturing & 3D Printing

Small-scale additive manufacturing has revolutionized the prototyping and repair landscape by transforming the traditional constraints of time, cost, and minimum order quantities. With desktop 3D printers, engineers and designers can rapidly iterate through design concepts in hours rather than weeks, testing form, fit, and function without the substantial investment traditionally required for tooling and molds. This agility extends beyond prototyping to the production of replacement parts, where small-batch additive manufacturing eliminates the need to maintain extensive spare parts inventories or wait for long lead deliveries. Whether printing a custom bracket for an aging machine or rapidly prototyping a new product feature, these compact systems bring industrial-grade manufacturing capabilities directly to the point of need, dramatically reducing development cycles and downtime while enabling unprecedented design freedom and customization.

TIME noted one product changing the game in 3D printing by dramatically improving print speeds:

Formlabs’ Form 4 creates stunning parts that always fit, rivaling injection molded parts.

We have covered the Form 4 and Form 4L from the very beginning of its launch back in April 2024. There have been thirteen mentions of Formlabs since the beginning of Exponential Industry and they are among the leaders in the Exponential Industry Index for the ‘Machinery : Additive Manufacturing : 3D Printer’ category. The past week, we covered how Brose leverages SLA and SLS using the Form 4 for a component in one of every three new automobiles.

“We were able to print them on Form 4 at a much cheaper cost than flying those parts over here and ordering minimum order quantity stock — which required us to order several millions of those parts. We had them rapidly available and didn’t have to wait for anything.”

Matthias Schulz, Manager, Seat Prototyping, Brose North America

Other competition includes HP which is also known for its Multi Jet Fusion (MJF) technology and fast print speed and Markforged’s industrial 3D printer which can print both metal filaments and composites with continuous fiber reinforcement.

Humanoid & Robotic Workforce

Humanoid robots represent a compelling solution to the ongoing labor challenges in manufacturing and logistics, particularly because they can seamlessly integrate into environments already optimized for human workers. Unlike specialized industrial robots that require significant facility modifications, humanoid robots can navigate existing workspaces, use standard tools, and adapt to multiple tasks—from picking and packing in warehouses to assembly line work in factories. Their anthropomorphic design allows them to reach into tight spaces, manipulate objects with human-like dexterity, and work alongside human colleagues without requiring extensive workplace redesign. While current limitations in AI, balance, and fine motor control mean they're not yet ready for widespread deployment, rapid advances in these technologies suggest that humanoid robots could become a vital part of the workforce, particularly for repetitive or physically demanding tasks that are increasingly difficult to staff in many markets. The key advantage lies not in replacing human workers, but in complementing them by handling tasks that are ergonomically challenging or better suited to tireless mechanical precision.

TIME mentioned two inventions in humanoids:

Figure’s Figure 02 claims to be the world’s first commercially viable autonomous humanoid robot.

Agility Robotics’ Digit is the first human-centric, multi-purpose robot made for logistics work.

We’ve dedicated a lot of space to humanoids over the last year since Agility Robotics reignited the humanoid form factor craze with $20 million in new investment in September of last year. Figure emerged on the scene with their announcement of a commercial agreement with BMW Manufacturing in January 2024. Don’t sleep on competition from Tesla, Boston Dynamics, and various Chinese companies tracked on our humanoid topic page.

Textiles & Circular Economy

The staggering scale of textile waste represents one of our most pressing yet underappreciated environmental challenges, with millions of tons of clothing and fabric materials entering landfills annually. However, breakthrough innovations in fiber recycling and synthetic biology are beginning to transform this linear system into a circular one. New processes can now break down discarded cotton garments at the molecular level and reconstitute them into fibers that match or exceed the quality of virgin cotton. Simultaneously, bio-engineered yarns and fabrics are emerging that are designed specifically for end-of-life recycling, while maintaining the performance and aesthetic qualities consumers demand. These innovations extend beyond just cotton – advanced polymer science is enabling the creation of fully recyclable synthetic fabrics that can be endlessly reprocessed without quality degradation. This technological convergence of bio-based materials, chemical recycling, and circular design principles promises to revolutionize the textile industry, turning today's waste into tomorrow's raw materials.

TIME mentioned two inventions in textiles:

Ambercycle’s cycora process creates regenerated polyester made from end-of-life textiles, offering the same versatility and strength as conventional materials, at a fraction of the environmental costs.

GALY’s Literally Cotton helps transition the world to cellular agriculture.

We picked up on Ambercycle back in June 2021 with their partnership with Avery Dennison to launch an intelligent digital care label solution and subsequent funding round in August of this year. GALY’s Series B was captured in September. Big changes continue to roll out within the textiles industry as fast fashion transitions into sustainable lightning-fast fashion.

Smart Agriculture

Precision and regenerative agriculture represent a transformative approach to feeding our growing global population while actively healing our planet's ecosystems. By combining advanced sensors, AI-driven analytics, and autonomous systems, precision agriculture enables farmers to apply water, fertilizers, and pesticides with unprecedented accuracy – reducing waste while maximizing yields. Meanwhile, regenerative practices such as no-till farming, cover cropping, and rotational grazing are proving that we can sequester carbon while building soil health and biodiversity. The integration of these approaches is creating a new agricultural paradigm where technology enables rather than fights natural processes. Early adopters are demonstrating that these methods can not only match or exceed conventional farming yields but also improve water retention, increase soil organic matter, and enhance crop resilience to climate extremes. This fusion of ancient wisdom with cutting-edge technology offers a viable path to not just sustainable but regenerative food production at scale.

TIME mentioned one invention in agriculture:

Guardian Agriculture’s SC1 aircraft is a fully-autonomous, eVTOL with precision spraying to reduce waste.

We picked up on Guardian Agriculture’s Series A in June of 2023. AI and electrification are transforming agriculture led by Monarch Tractor and long-time leader John Deere.

Energy

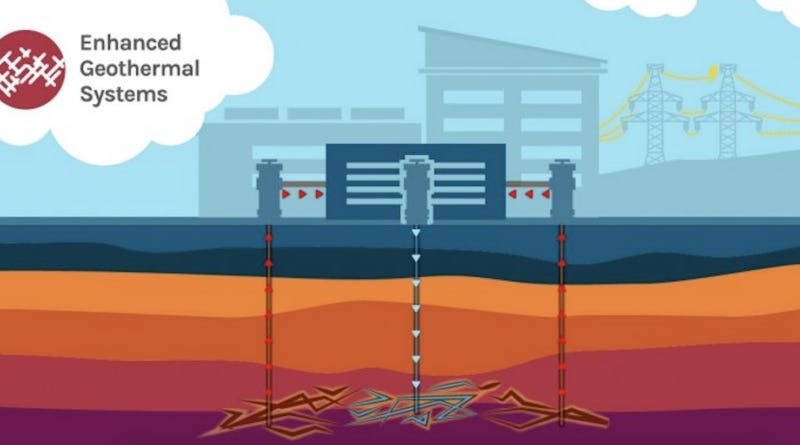

Beyond traditional renewables wind and solar, a new wave of innovative energy technologies is reshaping our approach to power generation and storage. Deep geothermal systems are unlocking the Earth's virtually limitless heat reserves through advanced drilling techniques and closed-loop systems, offering baseload power generation independent of weather conditions. Gravity-based energy storage solutions are elegantly simple yet powerful, using surplus energy to lift heavy weights that can later generate electricity through controlled descent – providing a cost-effective, long-duration storage alternative to batteries. Meanwhile, organic waste conversion technologies are transforming what was once considered trash into valuable energy resources, using advanced biochemical processes to convert food waste, agricultural byproducts, and other organic materials into biogas, sustainable fuels, and high-value chemicals. These diverse approaches share a common thread: they tap into previously overlooked or underutilized resources, offering new pathways to energy independence while simultaneously addressing waste management challenges and reducing carbon emissions.

TIME mentioned three inventions in energy:

Fervo Energy’s FervoFlex system uses horizontal drilling technology adapted from the oil and gas industry at scale to deliver commercially viable 24/7 geothermal energy.

Energy Vault’s EVx Gravity Energy Storage System introduces a highly scalable and modular architecture that can scale to multi-GW-hour storage capacity.

Arbor’s Power Station leverages recent advancements in oxycombustion and supercritical turbomachinery in a system that not only generates clean, reliable baseload power but also removes carbon dioxide.

Fervo Energy has been mentioned three times over the past 18 months, while Energy Vault and Arbor are new to our coverage. I’m a bit surprised that LuxWall’s LuxWall Enthermal™ high-performance glass technology which is designed to reduce energy consumption with high R-value energy-efficient vacuum insulating windows nor Reflect Orbital’s sunlight-reflecting satellite constellation was not picked up by TIME.

Transportation

The transportation sector is undergoing a revolution that's making travel safer, cleaner, and more efficient across all modes. Advanced AI-powered inspection systems are transforming vehicle maintenance, using computer vision and sensor arrays to detect potential failures before they occur, dramatically reducing downtime and improving safety. In aviation, hydrogen fuel cell systems are emerging as a viable path to zero-emission flight, particularly for regional aircraft, offering greater range than battery-electric alternatives while producing only water vapor as exhaust. Meanwhile, innovative de-icing technologies are eliminating the need for environmentally harmful chemicals through solutions like pulse-electromagnetic systems and superhydrophobic surfaces that prevent ice formation altogether. These developments represent not just incremental improvements but fundamental shifts in how we approach transportation maintenance and operations, promising reduced environmental impact while improving reliability and safety across the entire transportation network.

TIME mentioned three inventions in transportation:

UVeye’s Automatic Vehicle Inspection products produce high-resolution imagery in seconds and then process the images with machine learning algorithms to expose mechanical and safety issues within a detailed report.

ZeroAvia’s ZA600 contains a state-of-the-art fuel cell and electric motor technology combine to create an unparalleled aircraft engine with improved operating economics and zero-emissions within 10-20 seat aircraft.

De-Ice’s heating strips avoids chemical spray methods to eliminate weather-related departure delays and carbon emissions.

UVeye has been tracked since their joint presentation with RoboTire in December of 2021. ZeroAvia first showed up in Exponential Industry with their Series C funding round following prototype testing. De-Ice is new to our coverage. Other notable transportation inventions include the Boring Company’s fast-to-dig, and low-cost transportation, utility, and freight tunnels such as the Las Vegas loop launched this year.

Recalibrating Our Innovation Compass Beyond the Headlines

When publications like TIME release their innovation lists, they provide more than just a spotlight on breakthrough technologies—they offer a valuable calibration opportunity. By analyzing which innovations make these curated lists, we can retroactively trace their development paths, refining our early-warning systems and assessment criteria.

As we look ahead, the challenge isn't information scarcity but signal isolation. The pace of innovation across industrial sectors continues to accelerate, making it increasingly crucial to filter out the noise and focus on technologies with genuine transformative potential. That’s why I started Exponential Industry, and I plan on continuing to share with you the signals that I uncover.