Technology Capabilities Matter to Manufacture Mastery

A review of Manufacturing Mastery, building a flight path to business longevity through technology capability adoption.

In the dynamic world of manufacturing, the pursuit of longevity can feel much like embarking on an interminable transcontinental flight. Just as the sun never truly sets, the wheels of progress continue to turn, driven by both innovation and steadfast management. "Manufacturing Mastery: The Path to Building Successful and Enduring Manufacturing Businesses" by Rebecca Morgan serves as a guide to illuminating the importance of robust business operating systems in achieving lasting success. This book review explores how technology can assist in developing and executing business strategies. So, fasten your seatbelts and prepare for takeoff as we navigate the vast skies of business acumen and technological prowess that propel the manufacturing industry forward.

In most large companies, the “general” in general manager is emphasized. At Apple, there are no general managers in any intention of the phrase. Leaders invest most of their time in learning and owning, very little in delegating. They must have expertise in their areas of responsibility, which explains the attention to learning. Few mid-size manufacturers rely on leaders actually learning and gaining new expertise; even fewer larger ones do. If the executive team of an organization believes it has all the expertise it will ever need, endurance is not within the realm of possibility.

Ignite a learning revolution in your organization by sharing Exponential Industry – where technology leadership and expertise build manufacturing endurance.

Betting on Vertical Takeoff over Gradual Ascent

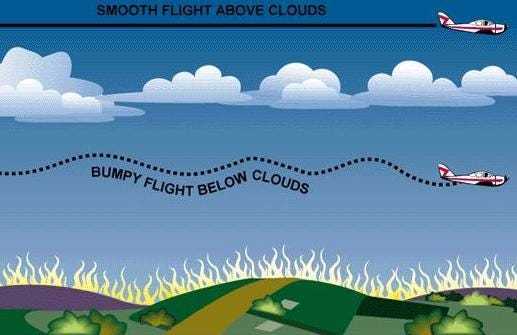

Continuous improvement can be likened to the gradual ascent of an aircraft toward its cruising altitude. It's a tried and true approach, methodically climbing higher through incremental progress and well-established protocols. This steady rise allows for assessing risks and fine-tuning strategies along the way, ensuring a stable flight path toward success.

However, we must remain aware that in today's competitive landscape, there are companies aiming for a more audacious approach, akin to vertical takeoff. These ambitious enterprises embrace disruptive technological innovation, seeking to skyrocket past their competitors boldly and daringly.

Manufacturing Mastery aptly underscores this shift in the industry, stating

"Continuous Improvement (CI), a concept considered the gold standard for advancing value a decade ago, can now be outpaced by advances in design and technology. The breakthroughs enabled by those developments can create step-function increases or entire revolutions in delivered value. No manufacturer can afford to ignore those factors."

This powerful insight serves as a reminder that the manufacturing landscape is changing rapidly, and businesses must adapt and evolve to stay ahead, lest they risk being left behind by the breathtaking vertical climb of their more audacious competitors.

Manufacturing Mastery then presents a valuable method for tracking developing technologies, emphasizing the importance of staying aware of and monitoring emerging innovations that can add value to or disrupt your industry, without being overwhelmed by the multitude of options. Here at Exponential Industry, we aid in this endeavor by providing a weekly digest and blog posts that serve as a curated source of validated technologies. By offering well-researched and first-hand experience with emerging technologies, Exponential Industry helps feed these cutting-edge advancements into your monitoring methods, streamlining your ability to identify and capitalize on valuable opportunities in a rapidly changing world.

Flying Through Turbulence

The world of technology can sometimes feel like flying through turbulent skies, surrounding us with unpredictability while shaking the foundation of our decisions. In the next passage, Rebecca constructs an analogy on how to think about technical debt, guiding us through its implications and impact on a company's flexibility and future.

Technology often creates lingering costs and limitations, just as other major infrastructure, investments in your business do. Estimating the “costs to undo” makes sense. The concepts of technical debt and technical capital have parallels in our physical worlds. They are akin to the limiting underbelly of traditional manufacturing investments and the empowering equipment we leverage daily. To understand technical debt, think of the locations of monuments in your operations that constrain flexibility. Then, like older equipment, add in the high potential that the technology will not be supported in the future. The “costs to fix” - ones that arise when shortcuts are taken to meet a deadline knowing full well that resources will be required later to overcome or fix those tactics - are also part of technical debt.

Leading manufacturers are using open-source software and data and simulating digital twins in the metaverse to reduce the amount of technical debt incurred.

Utilizing open-source software reduces the risk of technology obsolescence and enhances a system's sustainability by leveraging the power of collaborative development, interoperability, and adherence to open standards. With a community of developers constantly working on improvements and updates, open-source software remains up-to-date and adaptable. Its flexibility enables seamless integration with other systems and technologies, and the avoidance of vendor lock-in ensures that organizations can freely choose and switch between solutions that best suit their needs, promoting adaptable and sustainable systems over time.

Digital twins improve the likelihood of finding high-quality designs and reduce lifecycle costs for complex systems. By creating accurate virtual representations of physical assets, processes, or systems, engineers and designers can analyze multiple design iterations without physical prototypes, identify potential issues early, and make informed decisions based on real-time data. This collaborative approach in a shared metaverse promotes the efficient exchange of ideas, refinement of designs, and increased chances of discovering viable solutions for managing complex systems.

The collaboration enabled by these technologies resembles the seamless coordination between pilots and air traffic control, working together to navigate the skies and avoid turbulence, ensuring that the organization's design decisions and financial strategies are aligned, and being unafraid to chart new courses above the clouds.

Soaring to Cost-efficient Heights

Once the initial turbulence subsides and the technology is successfully integrated, companies can soar to greater heights by capturing new value opportunities and pursuing innovative business models. Rebecca discusses a changing focus needed amongst financial stakeholders to create the most impact on your business.

Most budgeting processes in manufacturing organizations insist on cost reduction from operations. Understanding total cost of ownership (TCO) and better yet, supply chain total costs (SCTC), would be far more effective in moving your organization toward the mission and vision about which you care deeply. Insisting purchasing negotiate lower prices with suppliers may seem obvious, but it is often a damning expectation. It makes more sense to work with suppliers to reduce TCO and SCTC. Reducing time and variability can have a much greater positive impact than price reductions.

Any technology capability requires a robust connection to business value to gain adoption. When insights are shared throughout the organization, new ways of doing business emerge and these capabilities can compound for the next 100 years.

With the shared insights of commercialization and finance, operations can proactively develop profitable products that the market will buy, ensure reliable delivery of value promised, and serve and retain customers. By becoming engulfed in furthering enterprise capabilities, it can propose potential capabilities to commercialization and finance. Not simply new machines. New capabilities can create amazing value. Consider how Rolls-Royce uses data from its jet engines to advise customers on fuel efficiency, improved maintenance, and better flight plans.

Endless Flight

Just like in flight, the one constant is that technological progress is inevitable. Enduring businesses must recognize this reality and embrace a mindset of constant adaptation in order to not just survive but thrive. By staying attuned to emerging technologies and continuously reevaluating their strategies, organizations can successfully navigate the winds of change and ensure their ongoing success. In this journey, adaptability and resilience are the wings that enable businesses to soar above the competition and (autonomously) chart a course toward a prosperous and sustainable future.

The changes impacting manufacturing are coming at us from all directions, more quickly than ever before. Sensors have been around for what feels like forever, but now they massively impact our options and the value we can provide.

Overall, Manufacturing Mastery is an enjoyable read with only a sprinkle of commentary on manufacturing technology. The business lessons are timeless, but the details on how to endure through the adoption of technology remain cloudy, and that’s where Exponential Industry comes in to help.

🤖 ChatGPT was used in the preparation of this post, see how.