Spotting a Way to Manufacture Efficiently

This week: Shenzhen speed run (paid), humanoid hands, metals feedstock, laser DED process control, 3D print multiplexing nozzle tech, battery dendrites, quantum sensors, LeRobot plugins

Shop Talk

Capturing this week’s zeitgeist

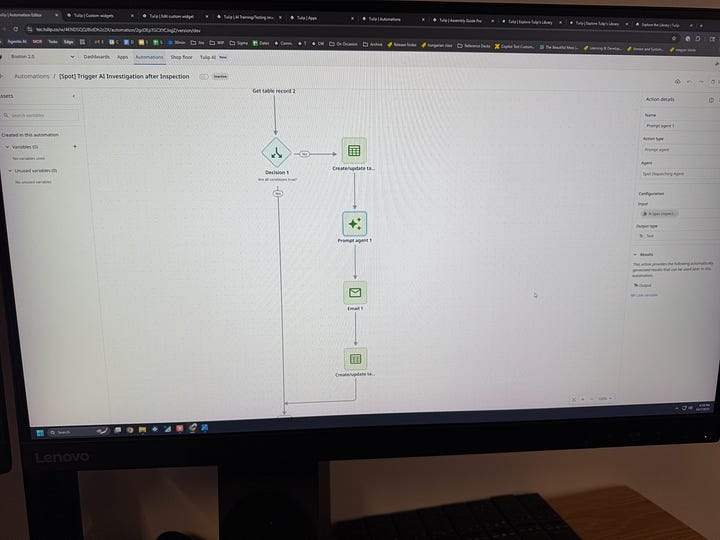

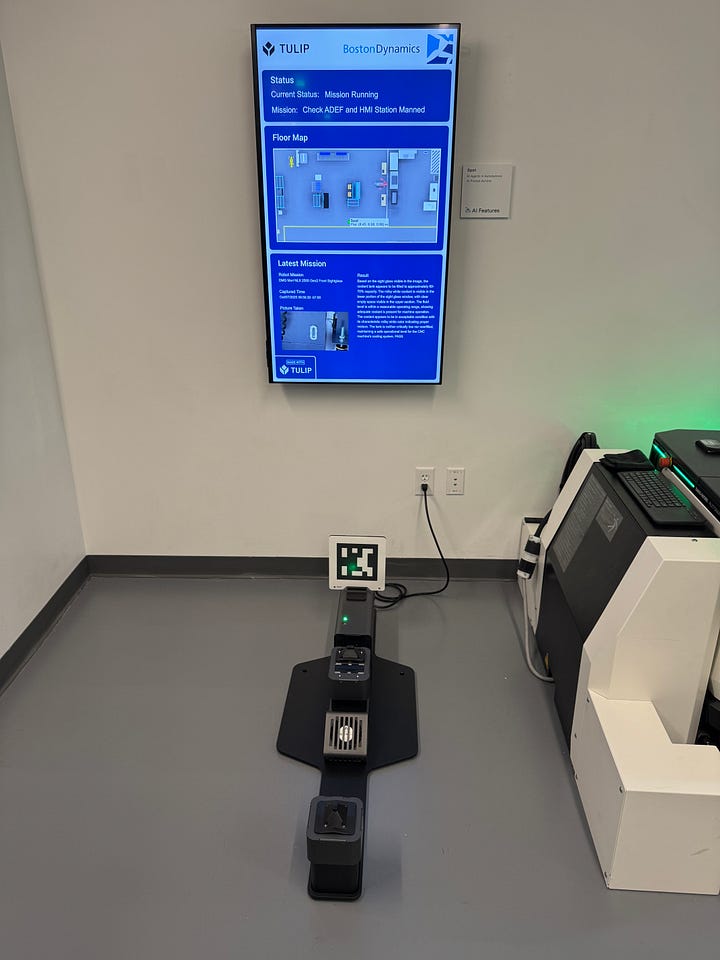

This past week at Tulip’s Operations Calling conference, I got a hands-on look at the future of industrial AI by tasking a Boston Dynamics Spot robot to autonomously assess the experience center and write a report on its findings. This demonstration of an AI agent workflow is a microcosm of a massive industry shift, underscored by companies like Energy Robotics raising $13.5M to scale the AI software brains for these autonomous inspections, and hardware innovators like LG Energy Solution providing the advanced batteries needed to power the next-generation SPOT2. It was a clear reminder that the entire ecosystem, from AI agent frameworks to the essential hardware, is rapidly advancing to make autonomous operations a present-day reality.

📅 Next up: Modern Machine Shop’s Top Shops Conference 2025, November 11-12, Charlotte, NC, USA is the event for CNC machining professionals to find data-driven, peer-reviewed best practices for machining technology, shopfloor practices, business strategies and human resources.

Assembly Line

This week’s Industry 5.0 breakthroughs and frontier technologies of the built world.

🏭🇺🇸 Sharpie Found a Way to Make Pens More Cheaply—By Manufacturing Them in the U.S.

Newell Brands successfully reshored the manufacturing of its Sharpie markers to a factory in Tennessee, demonstrating that technology can make U.S. production cheaper and more efficient than overseas outsourcing. The transition was enabled by a nearly $2 billion investment focused on automating the production process with advanced robotics for tasks like assembly, packing, and quality control, which increased production speeds by three to four times. Rather than replacing its workforce, the company retrained existing employees for higher-skilled roles such as automation engineering, resulting in a 50% increase in average wages while maintaining the same employee count. This strategic use of technology and workforce development has allowed Newell to lower production costs, avoid price increases, reduce shipping times, and improve product quality, proving that domestic manufacturing for high-volume, low-cost goods can be highly competitive.

Read more at WSJ

🫲🦾 What’s in a humanoid hand? | Boston Dynamics

Read more on Interesting Engineering and discuss with Boston Dynamics on X

Commentary: The Misguided Quest for a Human-Like Robot Hand /Caixin/

Enhancing gripping stability for delicate object handling: frictional insights into textured soft pads /The International Journal of Advanced Manufacturing Technology/

♻️ Tariffs Are Making Copper Harder to Get. Recycling It Could be a Quick Fix.

Copper is an essential commodity facing critical demand due to its fundamental role in fueling electrical equipment, from electric vehicles to the data centers that power artificial intelligence. The AI boom, in particular, is creating a massive need for the metal, with projections indicating that new data centers alone will require an average of 400,000 metric tons of copper annually over the next decade. Beyond its economic importance, copper is also a national security priority, as it is a critical component in defense systems like missiles, making a stable supply vital. To help meet this surging demand and increase supply chain independence, recycling offers a much faster solution than opening new mines. Companies like the German-based Aurubis are stepping in to fill this need, having recently launched one of the largest and most advanced multimetal recycling plants in the U.S. to reclaim copper from various waste sources.

T-Line Compact, the Revolution in ingots production /Tera Automation/

US government to take 10% stake in Canada’s Trilogy Metals /FT/

The Welding World Model

Find links to the topics mentioned at Industrial AI Podcast

3️⃣🖨️ Northwestern researchers advance digital twin framework for laser DED process control

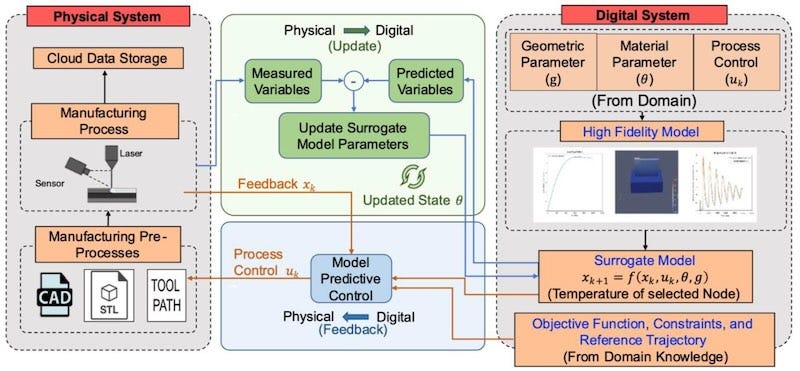

Researchers at Northwestern University and Case Western Reserve University have unveiled a digital twin framework designed to optimize laser-directed energy deposition (DED) using machine learning and Bayesian optimization. The system integrates a Bayesian Long Short-Term Memory (LSTM) neural network for predictive thermal modeling with a new algorithm for process optimization, establishing one of the most complete digital twin implementations for metal additive manufacturing to date.

It builds toward real-time adaptive control in DED, an additive process known for its potential in functionally graded materials and repair applications, yet often limited by thermal instability and part-to-part variability.

Read more at 3DPI and Journal of Manufacturing Systems

‘Next-gen 3D printing’ enables printing with two different materials at once — faster, lighter, and more precise multiplexing nozzle tech demoed by U.S. gov’t scientists /Tom’s Hardware/

Printable aluminum alloy sets strength records, may enable lighter aircraft parts /MIT News/

🔋 We’ve Been Using Lithium-Ion Batteries for Decades. Now We Know More About How They Work

A typical lithium-ion battery works via a chemical mechanism called intercalation. Essentially, during battery discharge, lithium ions dissolved in an electrolyte solution insert themselves inside of a solid electrode. When the ions “de-intercalate” and return to the electrolyte, the battery charges.

The rate of intercalation governs everything from a battery’s net power to its charging speed—the reason the researchers found it imperative to better understand the underlying mechanisms, the paper explained.

Previously, scientists believed that lithium intercalation in a battery electrode was driven by a model describing how quickly lithium ions could diffuse between the electrolyte and the electrode. However, actual experiments hadn’t quite matched what that model predicted, suggesting to researchers that there may be another option.

Read more at Gizmodo and Science

Quantum Sensors Sidestep the Heisenberg Uncertainty Principle /IEEE Spectrum/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🦾🤖🦿 Figure AI designs Figure 03 humanoid for AI, home use, and scaling

Figure AI’s third-generation humanoid, Figure 03, represents a comprehensive redesign engineered for advanced AI integration, home and industrial applications, and mass production. A key focus is its enhanced sensory suite, which is purpose-built for its “Helix” physical AI model. This includes a new vision system with double the frame rate and a 60% wider field of view than its predecessor, along with redesigned hands featuring embedded palm cameras and highly sensitive tactile sensors capable of detecting forces as small as three grams. Designed for household environments, Figure 03 is 9% lighter than Figure 02, incorporates soft, washable textiles for safety, and supports 2 kW wireless inductive charging for autonomous operation. These features, combined with actuators that are twice as fast, also make it highly capable for industrial tasks requiring faster pick-and-place speeds. Critically, the launch is supported by a new manufacturing strategy that shifts to high-volume processes like die-casting and includes the creation of “BotQ,” a dedicated facility capable of producing up to 12,000 robots per year.

Read more at The Robot Report and discuss with CEO Brett Adcock on X

ResMimic: From General Motion Tracking to Humanoid Whole-Body Loco-Manipulation via Residual Learning /GitHub and arXiv/

🦾 New plugin system to support third-party hardware with LeRobot

This tutorial will explain how to integrate your own robot design into the LeRobot ecosystem and have it access all of our tools (data collection, control pipelines, policy training and inference). To that end, we provide the Robot base class in the LeRobot which specifies a standard interface for physical robot integration.

You can easily extend lerobot with your own custom hardware—be it a camera, robot, or teleoperation device—by creating a separate, installable Python package. If you follow a few simple conventions, the lerobot command-line tools (like lerobot-teleop and lerobot-record) will automatically discover and integrate your creations without requiring any changes to the lerobot source code.

Read on HuggingFace and discuss on X

Business Transactions

This week’s top funding events, acquisitions, and partnerships across industrial value chains.

🇨🇳 China’s Unitree heats up humanoid robot race as IPO valuation reportedly hits $7 billion

Unitree Robotics, a leading Chinese humanoid robot company, is planning an initial public offering that could value the company at as much as $7 billion (50 billion yuan). The company is actively preparing for its listing and expects to submit the required application documents in the fourth quarter of this year. While the amount Unitree aims to raise has not been disclosed, the company has stated it has been profitable since 2020, with revenues now exceeding $140.35 million (1 billion yuan). This potential IPO is significant as it could make Unitree one of the first publicly traded companies specializing in humanoid robots and would represent one of the largest Chinese tech listings in recent times.

Read more on CNBC

You Can Now Buy a Unitree Humanoid Robot at Walmart /TechNode/

🇨🇭 SoftBank to buy ABB’s robot business for $5.4 billion in push to merge AI and robotics

SoftBank Group has agreed to buy the robotics business of Swiss engineering group ABB in a $5.4 billion deal, as the Japanese investor forges ahead with a strategy to fuse robotics and artificial intelligence. The acquisition, announced on Wednesday, is the latest by founder and CEO Masayoshi Son to establish Softbank as a core player in the development of artificial intelligence.

SoftBank pushed into humanoid robotics a decade ago with its Pepper robot but later scaled back its ambitions. Its recent investments in the sector include Berkshire Grey and AutoStore, and it also led a $40 billion funding round in ChatGPT-maker OpenAI and in March bought chip design company Ampere for $6.5 billion.

Read more at Reuters and discuss on X

Beyond the headlines: Inside China’s multi-billion dollar industrial robotic arms market /Robotics & Automation News/

Softbank acquires ABB’s robotics business for $5.38B /TechNode/

🇺🇸🔋 Base Power Raises $1 Billion Series C to Build the Future of American Power

Base Power announced it has raised $1 billion in Series C financing, led by Addition. All other major investors are re-investing, including Trust Ventures, Valor Equity Partners, Thrive Capital, Lightspeed, Andreessen Horowitz, Altimeter, StepStone, Elad Gil, 137 Ventures, Terrain, and Waybury. New major investors include Ribbit, CapitalG, Spark, BOND, Lowercarbon, Avenir, Glade Brook, Positive Sum, and 1789.

In less than two years, Base has deployed more than 100 MWh of residential battery capacity. That pace makes it one of the fastest-scaling distributed energy platforms in the U.S., driven by organic growth, partnerships with leading homebuilders like Lennar and with forward-thinking utilities. The company has also rapidly expanded operations, now serving homeowners across the Dallas–Fort Worth metroplex, Greater Houston, and the Austin region, with plans to expand nationally in the near future. To meet current and future demand, Base is building its first energy storage and power electronics factory at the site of the former Austin American-Statesman printing press in the heart of downtown Austin.

Read more at Business Wire and discuss with CEO Zach Dell on X

Why we invested in Base Power, creating the distributed future of energy /SamsungNext/

Why AI’s Future Depends on the Supply Chain: Inside the Energy, Construction, and Logistics Constraints of the Data Center Boom /Logistics Viewpoint/

Want more? Check out the paid analysis and 100+ bonus reads below 👇