Real Place, Real Facts, and Holiday Spice

Genchi genbutsu (real place, real facts) demonstrated in remote inspection, real-time closed-loop optimization, and engineering design tools.

Shop Talk

Capturing this week's zeitgeist

“Holiday Shutdowns and Future Plans,” a poem by Exponential Industry’s GPT.

The factories pause, in this festive cheer,

Tools at rest, the machines quiet, clear.

Workers smile, as they leave the floor,

Dreams of family, feasts, and much more.Yet in this stillness, we plan ahead,

For a new year of progress, our goals widespread.

Innovation whispers, in the silent halls,

Awaiting our return, to answer its calls.We'll embrace lean principles, with vigor anew,

Optimizing workflows, enhancing what we do.

Automation's promise, in the coming days,

Will guide our efforts, in so many ways.As lights twinkle, and laughter fills the air,

We cherish these moments, with those who care.

But soon we'll return, with a vision so bright,

To industries thriving, in the new year's light."

In case you still need tips for holiday decorations, Desoutter has you covered!

Assembly Line

This week's most influential Industry 4.0 media.

Toyota Outlines Future Production Processes

✍️ Author: Austin Weber

🔖 Topics: Gigacasting

🏭 Vertical: Automotive

🏢 Organizations: Toyota, Honsha Associates

The new strategy is rooted in the basic principles of the Toyota Production System (TPS), which includes a willingness to do things “for the benefit of someone other than yourself” and a “human-centered” approach to manufacturing. “What caught my attention the most was seeing see the famous genchi genbutsu (real place, real facts) now being done via video,” notes Obara.

Toyota’s next-generation EVs will be built upon a new modular structure in which car bodies are divided into three sections: front, center and rear. Giga-casting is one of the new production technologies that will make these modular structures possible. Currently, the rear section of the Toyota bZ4X EV is made with 86 sheet metal parts and 33 press processes.

“Whereas a typical changeover might take 24 hours and require a large crane, giga-casting molds, which weigh more than 100 tons, leads to even greater time loss,” says Shingo. “Our new approach to giga casting divides molds into two types: general-purpose molds that remain mounted on the machinery and specialized molds whose shape differs by car model. During a replacement, only the compact specialized molds detach themselves automatically from the general-purpose molds.” With these just-in-time mold changes—replacing only what is needed, when it is needed, in the quantity needed—Toyota is aiming to bring lead times down to 20 minutes or less.

Read more at Assembly

Inside (ONE) Our Next Energy's New Michigan Factory!

ANYmal Closes the Remote Inspection Loop with Aker and Cognite

🔖 Topics: Visual Inspection

🏢 Organizations: ANYbotics, Aker BP, Cognite

Aker BP, Cognite, and ANYbotics partner in pioneering offshore remote inspections with ANYmal X on the Valhall platform in the North Sea. ANYmal X, the only Ex-certified legged robot, was tested for integrated robotic inspections in offshore Ex-rated zones, showcasing the benefits of Cognite’s real-time digital twins and comprehensive AI-powered data platform.

Read more at ANYbotics News

Metal steam turbine blade shows cutting-edge potential for critical, large 3D-printed parts

🔖 Topics: Additive Manufacturing, 3D Printing

🏢 Organizations: Oak Ridge National Laboratory, Siemens, Lincoln Electric

Researchers at the Department of Energy’s Oak Ridge National Laboratory became the first to 3D-print large rotating steam turbine blades for generating energy in power plants. Led by partner Siemens Technology the project demonstrates that wire arc additive manufacturing is viable for the scalable production of critical components exceeding 25 pounds.

While the wait for large castings and forgings has decreased to seven or eight months, ORNL was able to print the blade in 12 hours. Including machining, a blade can be finished in two weeks, Kulkarni said. Although wire arc is a prominent 3D-printing technology, it had not previously been used to make a rotating component of this scale.

Read more at Oak Ridge National Lab News

MIRAI the AI-enabled Vision System Changing the Game

🔖 Topics: Machine Vision

🏢 Organizations: Micropsi Industries

Closing the design-to-manufacturing gap for optical devices

🔖 Topics: Lithography

🏢 Organizations: MIT, The Chinese University of Hong Kong

We introduce neural lithography to address the ‘design-to-manufacturing’ gap in computational optics. Computational optics with large design degrees of freedom enable advanced functionalities and performance beyond traditional optics. However, the existing design approaches often overlook the numerical modeling of the manufacturing process, which can result in significant performance deviation between the design and the fabricated optics. To bridge this gap, we, for the first time, propose a fully differentiable design framework that integrates a pre-trained photolithography simulator into the model-based optical design loop.

Read more at Neural Lithography

New Product Introduction

Highlighting new and innovative products and services

Canvass AI Unveils Real-Time Closed-Loop Optimization Using Prescriptive Analytics for Industrial Processes

🔖 Topics: Manufacturing Analytics, Autonomous Production

🏢 Organizations: Canvass AI

Canvass AI announced the availability of its real-time closed-loop optimization solution for process and sub-process level production.

The Canvass AI closed-loop optimization solution comprises of predefined data mapping, learning models, configuration files, AI workflows, and a setpoint optimizer. Using this framework engineers and operators can confidently apply virtual control to physical processes allowing them to constantly adapt to changing production conditions. Canvass AI’s solution overlays legacy OT investments such as APC and DCS to optimize process performance closer to the operating specification limits to maximize quality and output.

Read more at EIN Presswire

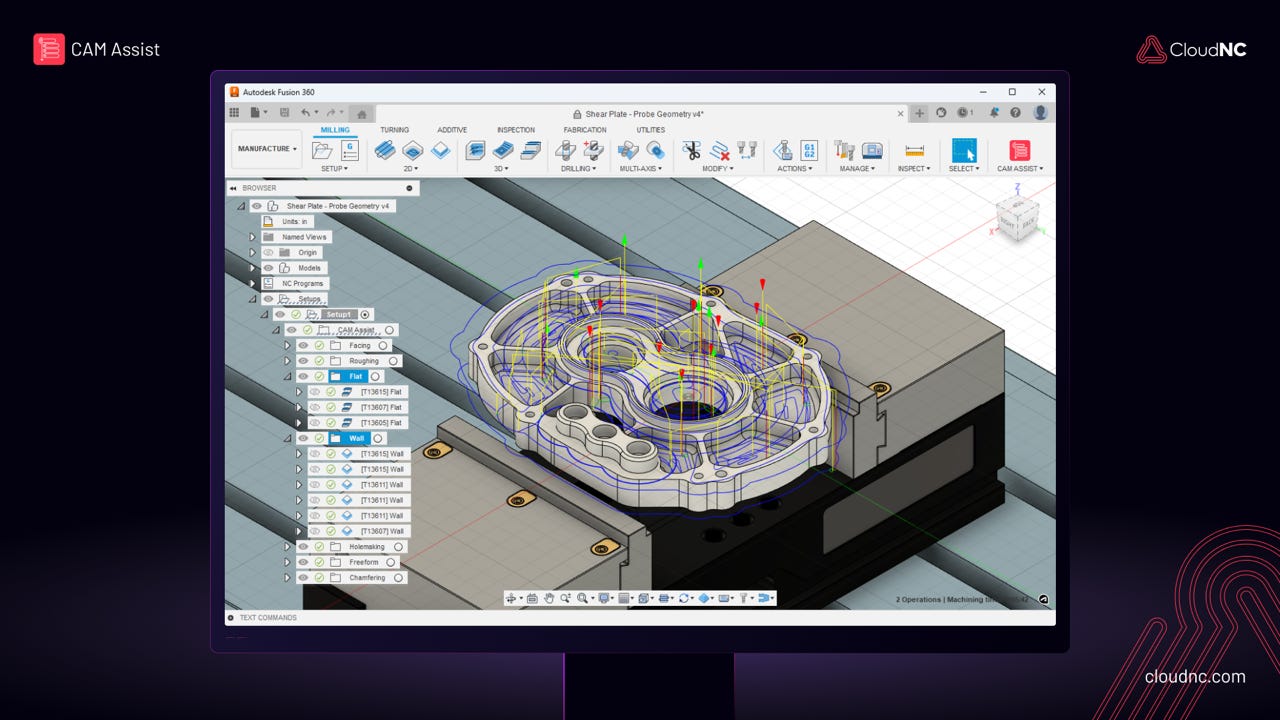

Pulling your punches: The greatest leap in CNC CAM programming since punch cards

🏢 Organizations: CloudNC

Theo Saville, CEO and Co-founder of CloudNC, has spent the past decade devising a better approach to Computer Numerical Control (CNC) programming. The result is CAM Assist, an AI-powered plug-in for Autodesk’s Fusion 360 software platform that has quickly garnered a reputation for being the biggest paradigm shift for the precision manufacturing sector in decades.

We knew we needed somewhere to test our solutions and we figured that no factory would allow us to use their production machines for experiments. Building our own factory gave us our own testing ground, as well as allowing us to measure the impact of our software on day-to-day operations.

Read more at The Manufacturer

Industrial Policy

How governments are shaping the future industrial landscape.

🇺🇸 Governor Hochul Announces $10 Billion Partnership for Development Center to NY CREATES’ Albany Nanotech Complex

Governor Kathy Hochul announced a $10 billion partnership with leaders from the semiconductor industry such as IBM, Micron, Applied Materials, Tokyo Electron. The partnership will fund the construction of a cutting-edge High NA Extreme Ultraviolet Lithography Center – the first and only publicly owned High NA EUV Center in North America – that will support the research and development of the world’s most complex and powerful semiconductors.

Read more at New York State Governor

🇬🇧 Manufacturers Urge Government to Appoint Minister

Members of Made in Group, which includes Made in the Midlands and Made in Yorkshire, say that Britain can further advance its position as the eighth largest industrial nation globally but the sector needs more effective support from the Government to do so. An open letter detailing the actions needed to help boost Britain’s manufacturing capacity was delivered to the pigeonhole of every MP.

Read more at The Manufacturer

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains

Armada Raises More Than $55M to Bridge the Digital Divide

🔖 Topics: Funding Event

🏢 Organizations: Armada, Founders Fund, Lux Capital, Shield Capital

Armada, an edge computing pioneer redefining the future of connectivity, compute and AI, today exited stealth. The company marks this milestone with a significant capital raise exceeding $55M, led by Founders Fund, Lux Capital, Shield Capital and 8090 Industries.

Armada provides a full-stack infrastructure solution, deployable on both on-premise and cloud infrastructures, to deliver optimal edge computing and cutting edge satellite internet connectivity to the world’s most remote regions. This empowers companies to harness the power of generative AI and predictive models where they are most needed, enabling a range of industries — from utilities and infrastructure to military and mining — to dramatically enhance their real-time processing, analysis and decision-making capabilities, right where their data resides.

Read more at Business Wire

Verve Motion Raises $20 Million in Series B Financing

🏢 Organizations: Verve Motion, Safar Partners, Harvard University

Pioneering the future of industrial safety, Verve Motion, a Harvard University spinout, today announced it has reached a significant milestone by securing $20 million in Series B funding. The Series B funding round, which will play a pivotal role in supporting the company’s goals of market expansion and scaling manufacturing to meet demand. This achievement marks a crucial step in the company’s rapid expansion and the widespread adoption of its innovative industrial-use connected wearable technology, SafeLift™ exosuit.

Read more at PR Newswire

Spore.Bio raises €8M for real-time pathogen detection in FMCG factories

🏢 Organizations: Spore.Bio, LocalGlobe

Spore.Bio announced that it has raised €8 million in Pre-Seed funding led by LocalGlobe to solve the critical health and safety challenges threatening the global fast-moving consumer goods (FMCG) market. The funding will be used to accelerate the development and deployment of Spore.Bio’s AI-powered technology and grow its team.

Spore.Bio has built the world’s first device for detecting pathogens immediately, directly on the factory floor. It uses advanced machine learning models to train its system to identify the concentration of bacteria in food, drink, pharmaceuticals and cosmetic products before alerting quality managers to the potential risks. Previously, quality sampling would typically take between five and 20 days, with products having to be sent off-site to external labs, at great time and financial expense.

Read more at Tech EU

AllSpice.io achieves $10m in venture funding for modernizing electronics design collaboration

🏢 Organizations: AllSpice

AllSpice.io, the hardware development platform that empowers engineers to modernize their collaboration and workflows, has raised an additional $6 million in venture capital. Investors participating in the recent round included Root Ventures, Flybridge Capital Partners, Benchstrength, Bowery Capital, and a group of angel investors. The funding is being leveraged to develop new features for its growing enterprise customer base and expand complex implementations, integrations, and additional ECAD format support.

Founded and built by engineers, AllSpice.io empowers fellow engineers to modernize their workflows - all through the power of Git. With automation, cross-team collaboration, and version control, engineers can develop hardware more efficiently.

Read more at PR Newswire

TeamViewer to drive smart factory innovation with strategic investments in manufacturing analytics and IoT

🔖 Topics: Partnership

🏢 Organizations: TeamViewer, Sight Machine, Cybus

TeamViewer, a leading global provider of remote connectivity and workplace digitalization solutions, today announced strategic investments in two pioneering companies for smart factory solutions: Sight Machine and Cybus.

Read more at PR Newswire

Audi drives the future of manufacturing

🏢 Organizations: Cisco, Audi, Volkswagen

Thousands of assets in the Böllinger Höfe plant operate under the aegis of Audi’s Edge Cloud 4 Production (EC4P), with critical networking and security support from Cisco. “Audi and Cisco shared the vision of getting rid of the compute hardware from the shop floor and virtualizing it,” Loeser concluded. “That’s one of the big reasons why we are actually deploying this today.

Read more at Cisco Newsroom

Mitsubishi Electric and TXOne Networks to Cooperate in Mutual Expansion of OT Security Businesses

🏢 Organizations: Mitsubishi Electric, TXOne Networks

Mitsubishi Electric Corporation and TXOne Networks Inc. announced that they have signed a long-term cooperation agreement covering technology development and marketing, aiming at expanding the operational-technology (OT) security businesses of both companies.

Read more at TXOne News