Raw Workflow to Finished Good

This week: Alaska fish processing, AI in AM into CAD, virtual prototyping of AI-as-a-Service, classification of manufacturing processes and finished components, green iron plant, rust-based batteries.

Shop Talk

Capturing this week's zeitgeist

Standing on the deck of a purse seiner in Petersburg, Alaska, watching a crew of five orchestrate the deployment of a 1,000-foot net with precision timing, I was struck by how this centuries-old practice operates at the intersection of tradition and today’s economics. These boats, $3 million vessels with $250,000 licenses, can haul 70,000+ pounds of salmon per load, earning crews 20-40 cents per pound when the market cooperates. Contrasted with smaller gillnets that can operate with crews of just one or two with an upfront cost of a few hundred thousand.

But Alaska's traditional fishing methods are just the beginning of a broader technological transformation reshaping the industry. Shinkei Systems has raised $22 million to deploy robotic processing units on commercial fishing vessels that use Japan's ike jime method, spiking fish brains to prevent stress hormone release and extend shelf life up to 3x while improving meat quality. Additionally, modern fish processing facilities increasingly rely on machine learning for quality grading, automation for packaging and food safety, and predictive analytics for inventory management. Meanwhile, companies like Mara Renewables are scaling algae-based omega-3 production as an alternative to expensive fish-derived nutrients, recently raising $12.5 million to expand into global markets.

Support the publication by becoming a paid subscriber and get industrial technology insights before it’s too late.

Assembly Line

This week's most influential Industry 4.0 media.

🖨️🧠 AI in AM: How AI will get the next 20 million users into CAD

✍️ Author: Laura Griffiths

Manufacturing plants are full of engineers who are full of ideas. But they’re not all equipped with the design skills to ‘triage’ what can or can’t be 3D printed and bring their ideas to life. For Backflip AI, that’s a huge opportunity. At Markforged, application engineers would often be sent to ‘walk the line’ at a company where, over time, they’d meet with thousands of engineers who knew exactly what they needed to make their lines run better – they just didn’t know how to make it.

That doesn’t mean Backflip is out to replace CAD. Instead, it wants to “turbocharge it” and act as a front end that allows users to quickly design their parts and flow through to their existing mainstream CAD software. It’s CAD agnostic and designed to work alongside major platforms like Siemens NX and Autodesk, having recently unveiled a plug-in that translates 3D scan data into fully featured parts.

Read more at TCT Magazine

Building CAD to USD Workflows with NVIDIA Omniverse /NVIDIA/

PartCrafter: Structured 3D Mesh Generation via Compositional Latent Diffusion Transformers /GitHub/

Manufacturing task-based optimization of multi-axis CNC machine tool architectures at the pre-design stage /The International Journal of Advanced Manufacturing Technology/

🛣️🧠 Virtual prototyping of AI-as-a-Service

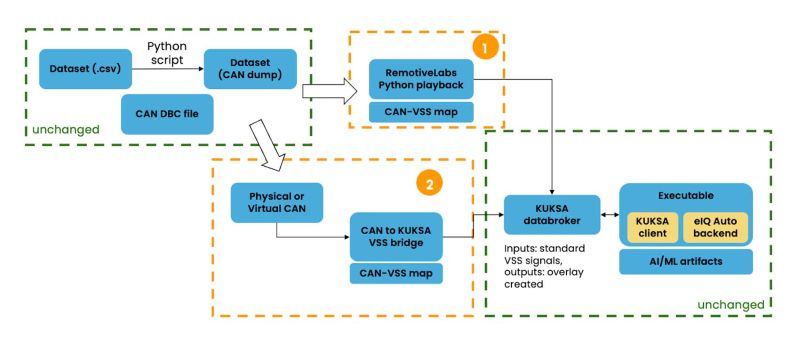

In this use case, Gergely Simon from NXP showcases a streamlined flow for developing and deploying an AI model for road surface classification. Starting with cloud-based prototyping and shared VSS data streams, the same setup is reused for physical deployment, without rework.

With this approach, NXP shows how modern automotive AI development can move faster and stay cleaner. Once the model is trained and validated, the exact same pipeline—CAN dump, DBC file, and VSS map—powers deployment on physical ECUs with no upstream rework.

Read more at Remotive Labs

🗜️🧠 AutoSplit: a two-stage AI architecture for enhanced classification of manufacturing processes with a focus on the identification of additive manufacturing components

✍️ Author: Mehdi Nazarian, Rafael Neves, Léon Klick, Robert Lau & Felix Weigand

In the product development phase of mechanical assemblies, engineers encounter an increasing variety of potential manufacturing routes for metal parts. Despite the advantages of additive manufacturing (AM), conventional methods often dominate due to a lack of interdisciplinary knowledge required for additive or hybrid manufacturing approaches. To streamline the development of hybrid manufactured components, this paper presents a novel two-stage methodology for automating part classification in manufacturing processes. A two-stage classification approach was selected to filter standard parts (e.g., screws, nuts, bolts), enabling a pre-filtering step that improves classification performance and reduces overfitting by minimizing the number of ST-components with similar features. The approach is trained on a comprehensive dataset of 20,000 CAD files sourced from GrabCAD, Fusion360, and TraceParts, evenly distributed across four categories. This methodology provides guidance for selecting appropriate manufacturing routes for both redesigns and new designs.

Read more at The International Journal of Advanced Manufacturing Technology

CNC Milling vs. 3D Printing: What’s Best for Precision Microfabrication? /BMF/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🛩️ From Lab to Launchpad: What We Really Did in Dubai

✍️ Author: Didier Papadopoulos

Building on a steady progression of testing at our Marina, CA, facility and at Edwards Air Force Base, our UAE test flights marked a phase of in-market validation that expanded the environmental envelope of our aircraft. Conducting flights in ambient temperature nearing 110°F provided critical data on thermal management system performance for every part of the aircraft, including battery packs, actuators, and electric motors. Sustained operation in a challenging set of environmental conditions (temperature, humidity, sand, dust, etc.) directly informs our operational models and showcases system reliability across diverse climates.

Read more at Joby Aviation

Boeing kicks off 777-8 Freighter Production /YouTube/ with the first drill into the 108-foot wing spar

MGI Engineering is set to use Argive’s 3D printed microturbines /TCT/ designed to reduce the number of parts the A300 turbine needs by a factor of four, providing a lighter, more efficient, compact power system for unmanned platforms and mobile operations.

🏭 Calix executes $44.9m ARENA grant for ZESTY Green Iron Demonstration Plant

Calix announced that it has executed final agreements on the award of a AUD$44.9 million grant from the Australian Renewable Energy Agency (ARENA) to build a Zero Emissions Steel Technology (ZESTY) Green Iron Demonstration Plant. The Demonstration Plant will have a targeted capacity to produce 30,000 tonnes per annum of hydrogen direct reduced iron (H2-DRI) or hot briquetted iron (HBI).

The Demonstration Plant is designed to enable toll processing of iron ores from a range of producers both within Australia and internationally. Targeted project outcomes aim to assist in progressing the viability of Australian iron ore in a low emissions steel value chain, support the development of a green iron industry in Australia, and support global deployment of the technology.

The Demonstration Plant’s toll processing of multiple ore types and grades is also designed to facilitate testing of the H2-DRI / HBI product by multiple steelmakers using different steelmaking routes. This aims to demonstrate ZESTY’s potential to provide flexible decarbonisation pathways, including substituting a portion of the iron ore charge to a blast furnace in the near term, and longer-term low emissions steel production via an Electric Smelting Furnace (“ESF”) / Electric Arc Furnace (“EAF”) route.

Read more at Calix

🔋 Rust-based battery connects to an electricity grid for the first time

An iron-air battery that stores and releases energy through a reversible rusting process has become the first of its kind to connect with a public electricity grid. On 30 July, the Dutch start-up Ore Energy announced its batteries had connected to the grid at Delft University of Technology in the Netherlands.

Many grid-connected batteries are now lithium iron phosphate ones manufactured in China. But they typically hold power for just 4 to 6 hours and are prohibitively expensive, says Marie. In contrast, the iron-air batteries developed by Ore Energy can store power for 100 hours or longer and are made from cheap and widely available materials.

Read more at New Scientist and Tech EU

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

MI2 Launches Dual-Track Innovation Search to Spotlight Problems and Solutions in Kentucky Manufacturing /InnoEngine/ Applications close September 4.

The Georgia Cleantech Innovation Hub is creating a broad set of partnerships and programs for founders developing solutions in renewable energy, food and land use, sustainable transportation, waste reduction, the built environment and other cleantech areas. /COX Cleantech Accelerator/

🇨🇦🦾🍄🟫 4AG Robotics Raises $40 Million Series B to Accelerate Global Adoption of Autonomous Mushroom Harvesting

4AG Robotics, the global pioneer in fully autonomous mushroom harvesting, announced the close of its $40 million CAD Series B financing, led by Astanor and Cibus Capital, with support from new investor Voyager Capital and existing investors InBC, Emmertech, BDC Industrial Innovation Fund, Jim Richardson Family Office, Stray Dog Capital and Seraph Group. This round follows a $17.5 million round in 2023, bringing total capital raised to $57.5 million in the past two years.

4AG's system uses AI-powered computer vision, precision suction grippers, and advanced motion control to autonomously harvest, trim, and pack mushrooms 24/7—without manual labor. Designed to retrofit into existing Dutch-rack infrastructure, the robots enable consistent quality, reduced labour costs, and real-time operational data for growers.

Read more at PR Newswire

🇰🇷 Doosan Robotics Accelerates Push to Become an AI Robot Solutions Leader with ONExia Stake /PR Newswire/

🇨🇦🦾📸 Apera AI Secures Series A Financing and Welcomes Four New Executives to Fuel Rapid Expansion

Apera AI, the leader in 4D Vision for industrial robotic automation, announced the closing of an over-subscribed Series A financing round. The round includes a significant new investment from BDC's investment arm, BDC Capital, Canada's most active venture capital investor, alongside increased participation from existing investors Lobby Capital, Flying Fish Ventures, and J-Ventures. The capital will accelerate Apera AI's rapid growth, enabling further investment in people, processes, and product innovation in 4D Vision technology for AI-powered robotic automation.

Apera AI's patented 4D Vision platform combines cutting-edge 3D vision with AI—the "fourth dimension"—to give industrial robots human-like vision and advanced artificial intelligence. This enables high-speed, precise performance in applications such as bin picking, de-racking, and complex assembly. Unlike traditional 3D vision systems that often falter in real-world manufacturing, Apera AI's 4D Vision is powered by AI and enables robots to adapt to shifting bins, changing lighting conditions, worn grippers, and complex part geometry—unlocking robot speed, accuracy, and reliability in the most demanding industrial settings.

Read more at PR Newswire

🇺🇸 Matrice.ai Accelerates Mission to Industrialize Real-Time Vision AI with Strategic Funding Led by Voltage Park /Business Wire/

🇺🇸⚗️ Solidec Raises Oversubscribed $2M Pre-Seed Round to Reinvent Chemical Manufacturing

Solidec, a pioneer in clean chemical manufacturing, announced it has raised $2+ million in pre-seed funding led by New Climate Ventures (NCV), with participation from Plug and Play Ventures, Ecosphere Ventures, Collaborative Fund, Safar Partners, Echo River Capital, and Semilla Climate Capital, among others.

Solidec's breakthrough approach to chemical manufacturing replaces centralized infrastructure with modular, efficient on-site production using only air, water, and electricity. Solidec's platform is powered by modular reactors capable of producing many widely used chemicals, including hydrogen peroxide, formic acid, acetic acid, and ethylene without any post-processing steps required. Solidec is initially focused on the production of hydrogen peroxide, a critical chemical used across industries from semiconductor fabrication and critical metal mining to wastewater treatment.

Read more at PR Newswire

🇺🇸 Napino Tech Ventures and Teksun Launch Rapidise with $4M Seed Funding to Accelerate AIoT Product Innovation and Electronics Manufacturing /PR Newswire/

🤝 Tesla-Samsung $16.5 billion supply deal may spur chipmaker's US contract business

✍️ Author: Heekyong Yang and Hyunjoo Jin

Tesla has signed a $16.5 billion deal to source chips from Samsung Electronics, a move that could bolster the South Korean tech giant's unprofitable contract business but is unlikely to help Tesla sell more EVs or roll out robotaxis more quickly.

Tesla CEO Elon Musk said that Samsung's new chip factory in Taylor, Texas would make Tesla's next-generation AI6 chip. This could re-energize Samsung's project, which has faced long delays because the company had trouble retaining and attracting major clients.

Read more at Reuters

Energy Capital Partners and KKR Announce Development of Hyperscale Data Center Campus in Texas /Business Wire/

KKR Forms A$500 Million Strategic Partnership with CleanPeak Energy to Launch New Distributed Energy Platform /Business Wire/

Want more? Check out the paid analysis delivered weekly below 👇