Paint "The Part" Red

This week: SendCutSend machines "The Part", Tool and Die AI, Auto Shows off Paint Shop, Weather-aware Maintenance, AI agents in Factory Operations, Laser welding, Software-Defined Automation, new VC $

Shop Talk

Capturing this week’s zeitgeist

A customer of ours, Emanuel, began posting on X, challenging us to test our CNC capabilities with a crazy design. We didn’t think much of it until day four, when we realized the internet basically adopted this CNC part concept as its own. We had hundreds of people daring us to take on this challenge, how do we say no? Somehow it turned into us live streaming the whole process, which was a first for us, with 100,000 people watching for 14 straight hours.

Watch “Machining “The Part”: A Short Film“

... That’s a sign something bigger is happening. Turns out American manufacturing isn’t just alive and well, it’s entertaining when you let everyone peek behind the curtain.

... They want to see how things are built, they want to be part of the story, and we wanted to see how far modern CNC machinery could go. This was a fun project that turned into a full-blown engineering phenomenon, and it revealed just how big and engaged the online manufacturing community really is. Turns out, metal parts can have fans.

SendCutSend Founder and CEO Jim Belosic

The enthusiasm for manufacturing began emerging on X a little over a year ago in part due to the Reindustrialize movement (more on that below) and “The Gundo.“ The Part phenomenon could be the inflection point in making manufacturing cool throughout the USA. Jim and team have already been able seize the moment and through their exceptional service as they claim “48/50 LA Hard Tech companies use SendCutSend” /X/.

Exponential Industry hopes see manufacturing enthusiasm sprout throughout the rest of the world (Morocco, Malaysia, Indonesia, etc.) bringing prosperity and 4.8 jobs along with them /NAM/.

Also: Travel on a CNC Machine Tool Chip Conveyor /YouTube/

New in 2026: We are gifting a 1-year paid subscription to the first person to identify the content link AND cultural reference to the title/subject line of this week’s digest. Comment on this post with your guess before next week’s digest is released to be eligible! Last week’s answer.

Assembly Line

Reindustrialize Tool and Die with High-tech Hope

In this episode, Core Memory travels to the Motor City to see if a mix of old-school grit and new-school software can actually bring manufacturing back to the US. It’s a story about the intersection of “ruin prn” and high-tech hope, where founders are betting that the future of American industry isn’t in a clean Silicon Valley office, but in the grime of a revitalized factory floor.

Bringing back The Jobs Sent to China /YouTube/ running 16+ manufacturing processes, deliver 3,000+ part numbers every week, and prove that American manufacturing is not dead.

President Donald Trump visits a Ford factory in the Detroit area /YouTube/. The $160,000 Mechanic Job That Ford Can’t Fill /WSJ/. Ford & BYD in Talks for Hybrid-Vehicle Batteries /WSJ/

The UK is losing the industry that makes everything /Sky News on YouTube/ visiting chemical plants across the country.

Also: Detroit Auto Show kicked off January 14th going until January 25th

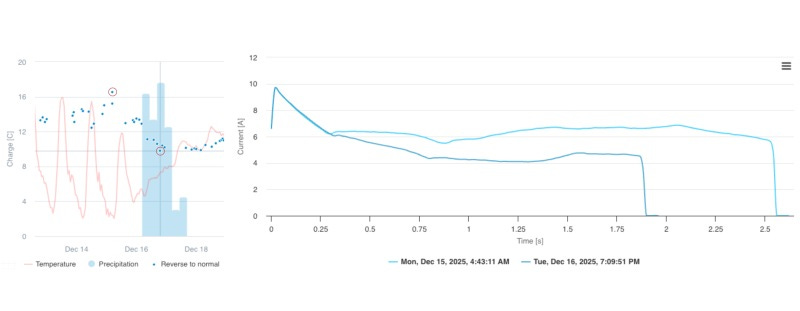

Weather-Aware Monitoring: Rethinking Point Machine Alerts

✍️ Authors: Nikhitha Rallabandi, Lukas Bernhard, Petra Pavlovic

Traditional Point Machine (PM) monitoring relies on fixed thresholds, such as maximum motor current, movement time, or vibration, to decide whether the machine is behaving normally or requires attention. This method assumes that the machine’s operating behavior remains stable over time. In reality, PMs are exposed to constantly changing outdoor conditions. PMs operate in some of the harshest and dirtiest environments in rail infrastructure. Interestingly, weather is one of the most significant external influences affecting their performance, reliability and overall lifetime. Because of this, the same machine may show very different electrical current profiles or movement durations under different weather conditions, even when nothing is mechanically wrong.

From this understanding, our solution calculates how much of the PM’s behavior is influenced purely by weather, which allows us to establish weather-adjusted expectations rather than rigid thresholds. Instead of sending an alert to operators whenever a weather-driven change occurs, KONUX Switch compares measurements to what is appropriate for that specific environment. This allows the solution to set smarter thresholds that change depending on conditions which results in more precise alerts. Unnecessary alerts caused by weather are significantly reduced, deviations that cannot be explained by the environment become easier to detect. This leads to clearer, more reliable alerts and far fewer false positives.

Read more at KONUX

Amperon Secures Investment from Samsung Ventures to Advance Energy Forecasting Technology /PR Newswire/

OpsMate - “the cool vendor” ; but why?

A sit down with James Zhang, co-founder and CPO of OpsMate AI, to explore the game-changing role of AI agents in factory operations. They discuss why traditional human-centric manufacturing models are hitting their limits and how a hybrid workforce—combining humans, robots, and digital agents—can address the skilled labor shortage and boost productivity.

Laser Welding at the Edge of the World

Explore the adaptations, operational realities and vision behind the installation of Wattsan’s 4in1 system and laser marker, tackling Antarctic extremes at Bellinghausen Station.

How Surety Automation modernized underground systems with digital communications and edge intelligence /Opto22/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

Dürr installs its Paint Shop of the Future for CEER

Dürr is building an innovative and sustainable paint shop for CEER, the first Saudi automotive company and Saudi-born EV brand. The order was placed back in 2023, and the project is currently in the installation phase. AGVs will transport car bodies flexibly between stations based on demand in the modular system. The latest application technology paints the interiors and exteriors of electric vehicles in the same box. In addition, there will be boxes for fully automatic two-tone application without overspray. High-tech and sustainability go hand in hand. Dürr supplies the latest generation of ovens which, combined with electric exhaust air purification systems, save energy and reduces CO2 emissions. The new facility will be one of the most advanced painting factories in the automotive world.

Read more at Dürr

The EcoPaintJet overspray-free paint applicator, invented by plant-engineering firm Dürr, plus novel decor coat paint from PPG (the second color applied), represents the world’s first implementation of precision application of automotive coatings /R&D World/

Rheinmetall develops Innovative Electrode Technology

The technology group Rheinmetall has successfully completed a project to develop a new electrode technology for alkaline electrolysis. This technology is a key technology for the energy transition in the field of hydrogen production. Preparations for the pilot production in the coming year have already been initiated. The aim is to significantly increase the power density and efficiency of water electrolysis to produce green hydrogen based on noble metal-free catalysts in comparison to current systems.

Series production is now underway: pilot production is scheduled to start at the St. Leon-Rot site next year. The production line is designed for electrode dimensions of up to two metres and is therefore suitable for multi-megawatt electrolyser systems. In addition, the volume scaling required for a successful energy revolution was already considered when selecting the process and production technology.

Read more at DLR Institute of Engineering Thermodynamics

Eos Energy Announces Indensity™: A Breakthrough in Battery Energy Storage /Eos/

Introducing Adam: The World’s First AI Mechanical Engineer

It’s PLA Time at Rivian’s 3D Printing Lab That Pursues a Need for Speed /Car and Driver/

Inside Jabil’s Advanced Catheter Development Lab /R&D World/

Business Transactions

This week’s top funding events, acquisitions, and partnerships across industrial value chains.

Announcing Lux Ventures IX /Lux Capital/ a $1.5B commitment to investing in the people turning sci-fi into sci-fact.

Why Are We Here? Why Did We Raise $15B? /a16z/ including American Dynamism ($1.176B), Apps ($1.7B), Bio + Health ($700M), Infrastructure ($1.7B), Growth ($6.75B), and other venture strategies ($3B)

Cerebras in Discussions to Raise Funds at $22 Billion Valuation /Bloomberg/

Rio Tinto and Glencore in Talks to Form World’s Biggest Miner /Bloomberg/

Tulip Secures $120M Series D to Give Frontline Workers AI Superpowers

Tulip, the leading frontline operations platform, announced that Mitsubishi Electric Corporation (TOKYO: 6503) has invested in and signed a strategic alliance agreement with the company, cementing a strategic commitment to overhaul digital transformation (DX) in manufacturing.

Read more at Business Wire

Where are the $100b companies in Boston? /Adapting/

Mytra Raises $120M Series C to Scale Operating System for Supply Chain

Mytra, the company building the operating system for supply chains, announced its closure of a $120M Series C round led by Avenir Growth. New investors Kivu Ventures, Liquid 2, D. E. Shaw, and Offline Ventures joined the round, alongside existing investors Eclipse, Greenoaks, Abstract Ventures, and Promus Ventures. The company’s strategic investors include Lineage and RyderVentures, the corporate venture capital arm of Ryder System, Inc.

Approximately 80% of industrial facilities have zero automation because of cost, complexity, and limited flexibility once installed. Mytra abstracts material flow into software-defined primitives — move, store, pick, route — that standardize operations and make every cubic foot of space addressable. Mytra’s early deployments have demonstrated 32% reductions in material handling labor and 34% improvements in storage density.

Read more at Business Wire

Flexxbotics Releases Free Download of Software-Defined Automation for Manufacturing Autonomy /Flexxbotics/ using parallelized data pipelines, Flexxbotics delivers bi-directional read/write data flows in real-time for heterogeneous plant assets with both open and proprietary industrial protocols – making multiple machines, PLCs, robots, test & inspection equipment, and IT systems operate with closed-loop control for greater autonomy.

Tive Secures $20 Million in Funding Led by Lightsmith Group /Tive/ for monitoring the real-time location and condition of shipments.

Logistics Software Market Projected to Exceed $35.8 Billion by 2033 /Sobel/

JetZero Raises $175 Million in Series B Financing to Transform Aircraft Innovation

JetZero, the U.S.-based start-up airplane maker designing the world’s first commercial all-wing airplane, announces it has raised approximately $175 million in its Series B financing, led by B Capital, a global multi-stage investment firm. United Airlines Ventures, Northrop Grumman, 3M Ventures and RTX Ventures, the corporate venture capital arm of RTX, among others, also participated in the round. To date, JetZero has raised and secured commitments of more than $1.0 billion, including government grants, incentives and commercial commitments.

The new capital will accelerate the development of JetZero’s full-size Demonstrator, a prototype designed to achieve at least 30% improved aerodynamics compared to traditional tube and wing aircraft. The Demonstrator is on track for its first flight in 2027.

Read more at PR Newswire

Inside the race to build the next generation of jet engines /FT/

Wing and Walmart expand drone delivery to 150 new stores coast to coast /Wing/

How Qatar Airways Tried to Outsmart Airbus - But FAILED Miserably /YouTube/

LIV4 raises €500k to Modernize Industrial Quality Management

LIV4 recently secured €500,000 in Pre-Seed funding led by a group of industrial-focused business angels, including executives from Blulink and Ognibene Power, with support from Intesa Sanpaolo and Banca d’Imola. The company will utilize the capital to expand its technical and product teams, enhance platform features, and accelerate market validation within the Italian industrial sector. At its core, LIV4 provides a proprietary generative AI platform designed to modernize quality management by automating the retrieval and analysis of enterprise data through natural language. The technology streamlines the creation of complex, regulation-compliant technical documentation and automates manual tasks like process traceability and validation, effectively turning quality management into a strategic, data-driven asset for sectors such as food and beverage and heavy manufacturing.

Read more at tech.eu

Lytra completes pre-seed financing for AI-driven manufacturing solution /tech.eu/

Looking for additional content? Paid subscribers get over 100 more stories delivered each week!