No-Huddle Manufacturing Drive

This week: BMW i5 and i3 factory, Dassault Systèmes Virtual Twin, Induction Stove, GPT-5-driven autonomous lab, Waymo World Model, autonomous walking and logistics, alignment-free wireless power

Shop Talk

Capturing this week’s zeitgeist

The current divide in robotics highlights the gap in application specific performance over general purpose capability: while Foundation Models offer impressive general reasoning and cross-platform common sense, they often fail the rigorous 99.9%+ reliability and low-latency standards required for industrial assembly lines. In controlled factory environments, small-scale, in-domain training—where a robot learns a specific task from a few dozen perfect human demonstrations—consistently outperforms massive general-purpose brains that are prone to physical unpredictability.

My favorite example is Path Robotics, which recently surpassed $100M in total bookings, with their Obsidian™ AI model for welding. I remain cautiously optimistic on Figure, Tesla, UBTech, Boston Dynamics, Agility, Humanoid, Apptronik, and many others that their humanoids with general reasoning will be suitable to wide-scale deployment into industrial environments just as Open AI and Anthropic have unleashed AI within software development and laboratory processes.

Which begs the question: Which OEMs will be first movers to successfully redesign manufacturing processes from first principles to take advantage of physical AI?

New in 2026: We are gifting a 1-year paid subscription to the first person to identify the content link AND cultural reference to the title/subject line of this week’s digest. Comment on this post with your guess before next week’s digest is released to be eligible!

Assembly Line

This week’s Industry 5.0 breakthroughs and frontier technologies of the built world.

🏭🚗 Inside Advanced Germany’s Factory Producing the New BMW i5 Electric

🚙 Major milestone: First pre-series vehicles for new BMW i3 roll off the assembly line at BMW Group Plant Munich /BMW/

🛻 Slate trucks will roll off the line later this year. How is the Slate factory progressing? /YouTube/

🦾 How the World’s Industries Are Being Transformed by Dassault Systèmes and NVIDIA

At 3DEXPERIENCE WORLD 2026, Dassault Systèmes and NVIDIA announced a long-term strategic partnership to establish a shared industrial architecture for mission-critical AI. This collaboration unites Dassault Systèmes’ Virtual Twin technologies with NVIDIA’s AI and Omniverse platforms to create science-validated industry World Models that understand the real world.

Read more at Dassault and NVIDIA

🦾 Robotic Automation System Assembles Switches /ASSEMBLY/ producing 3,000 assemblies per day with a 94 percent efficiency rate.

🤖👃 Ainos and Mirle Automation Partner to Bring Scent Intelligence to Robots and Quadruped Robots /Nasdaq/

🔌 Impulse Labs: Engineering a Better Induction Stove

Founded by a team of experienced engineers and innovators, Impulse Labs set out to solve a core limitation of traditional induction cooking. While induction is efficient and precise, it is ultimately constrained by residential electrical infrastructure. The grid, not the stove, becomes the bottleneck.

Impulse Labs’ solution is deceptively simple and deeply technical: integrate a medium-sized battery directly into the appliance. Paired with custom-designed power electronics, this approach allows the stove to deliver dramatically higher peak power and finer control than conventional induction systems—without requiring upgrades to the home’s electrical service.

Additive Drives: Minority Investment Raised From Nordic Alpha Partners /Pulse 2.0/ developing electric motors designed to deliver a leading thrust-to-weight ratio, strong efficiency per euro invested, and operation without rare earth materials. The company positions this rare-earth-free approach as both a performance advantage and a supply-chain resilience benefit.

🧠🦾🧫 Ginkgo Bioworks’ Autonomous Laboratory Driven by OpenAI’s GPT-5 Achieves 40% Improvement Over State-of-the-Art Scientific Benchmark

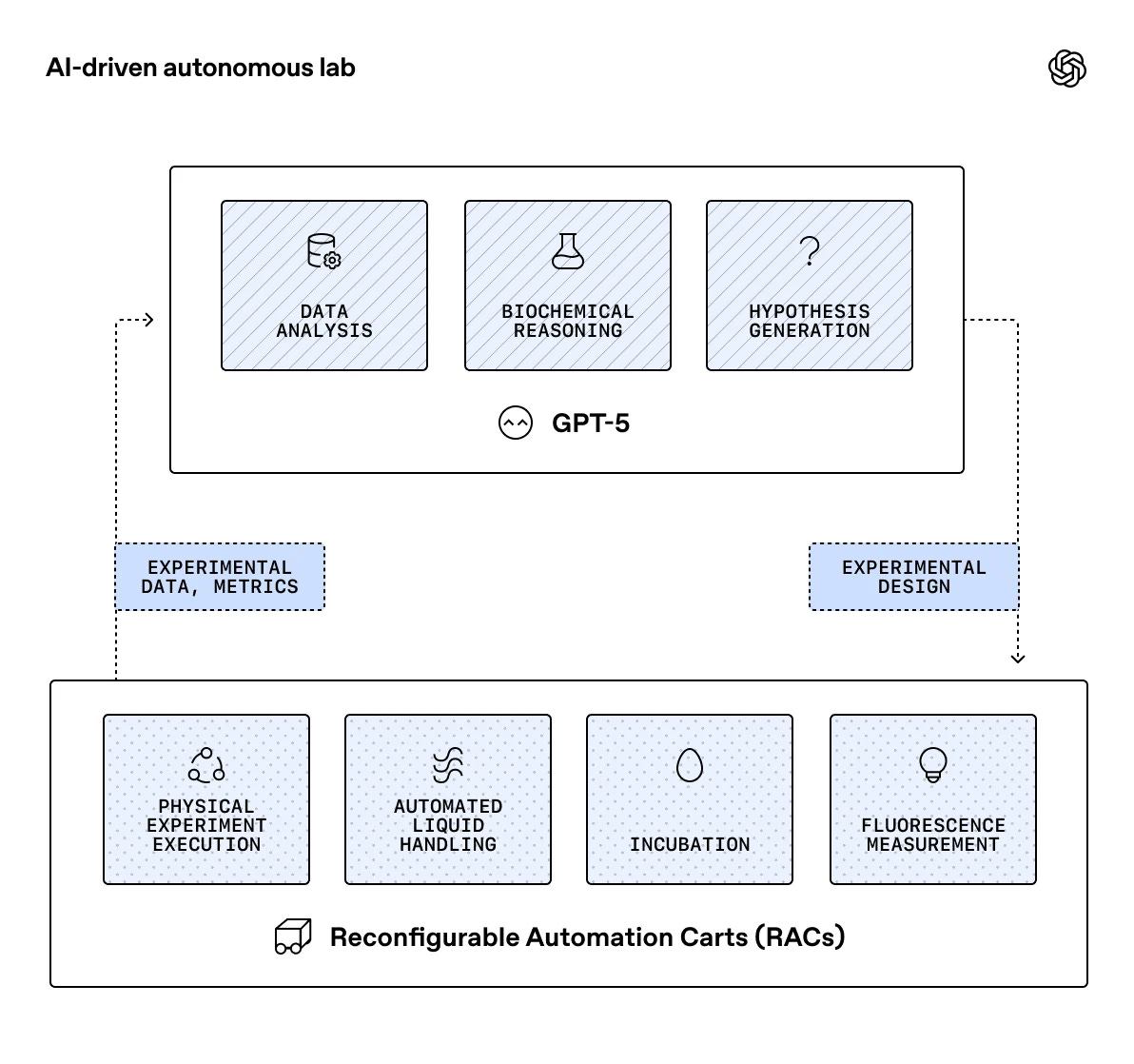

We used an autonomous lab, comprising a large language model (LLM) and a fully automated cloud laboratory, to optimize the cost efficiency of cell-free protein synthesis (CFPS). By conducting iterative optimization, the LLM-driven autonomous lab was able to achieve a 40% reduction in the specific cost ($/g protein) of CFPS relative to the state of the art (SOTA). This cost reduction was accompanied by a 27% increase in protein production titer (g/L). Iterative experimental design, experiment execution, data capture and analysis, data interpretation, and new hypothesis generation were all handled by the LLM-driven autonomous lab.

The interface between OpenAI’s GPT-5 LLM and Ginkgo Bioworks’ cloud laboratory incorporated built-in validation checks via a Pydantic schema to ensure that AI-designed experiments were properly specified. Experimental designs were translated into programmatic specification of multi-instrument biological workflows by Ginkgo’s Catalyst software and executed on Ginkgo’s Reconfigurable Automation Cart (RAC) laboratory automation platform, with human intervention largely limited to reagent and consumables preparation, loading and unloading. By integrating LLMs with programmatic control of a cloud lab, we demonstrate that an LLM-driven autonomous lab can successfully perform a real-world scientific task, highlighting the potential of AI-driven autonomous labs for scientific advancement.

Read more at bioRxiv, discuss with Ginkgo on X

💰 Polaron completes $8M funding round for materials science intelligence /Tech.eu/

🛰️ Elon Musk sits down with Dwarkesh Patel to discuss the economics of orbital data centers, the difficulties of scaling power on Earth, what it would take to manufacture humanoids at high-volume in America, xAI’s business and alignment plans, DOGE, and much more. /YouTube/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🧠🚙 The Waymo World Model: A New Frontier For Autonomous Driving Simulation

The Waymo World Model is built upon Genie 3—Google DeepMind’s most advanced general-purpose world model that generates photorealistic and interactive 3D environments—and is adapted for the rigors of the driving domain. By leveraging Genie’s immense world knowledge, it can simulate exceedingly rare events—from a tornado to a casual encounter with an elephant—that are almost impossible to capture at scale in reality. The model’s architecture offers high controllability, allowing our engineers to modify simulations with simple language prompts, driving inputs, and scene layouts. Notably, the Waymo World Model generates high-fidelity, multi-sensor outputs that include both camera and lidar data.

Read more at Waymo

Accelerating our global growth: Waymo raises $16 billion investment round /Waymo/

🦾🥶🦿 World’s First: Unitree Humanoid Robot Autonomous Walking Challenge in −47.4°C Extreme Cold

−47.4°C, 130,000 steps, 89.75°E, 47.21°N… On the extremely cold snowfields of Altay, the birthplace of human skiing, Unitree’s humanoid robot G1 left behind a unique set of marks.

💰 LimX Dynamics picks up $200M for humanoid robot expansion /The Robot Report/

🆓 Seeed Studio Releases Their Own Affordable and Open Source Robotic Arm /hackster/ called the reBot Arm B601 /GitHub/

🧠🦿 UBTECH Autonomous Logistics Vehicle Chitu α Completes PVT at Foxconn

UBTECH subsidiary company UQI’s autonomous logistics vehicles Chitu α has officially rolled off the production line at Foxconn New Energy Vehicle R&D Centre and completed the Production Validation Test (PVT). This achievement marks the successful Closed-loop Validation (CLV) of Automotive-grade (AG) Manufacturing. In the automotive-grade smart manufacturing system of Foxconn, this production run encompassed a complete closed-loop process from vehicle assembly, testing, to final delivery, laying a solid foundation for the upcoming mass production and delivery of Chitu α. Furthermore, the collaboration between industrial humanoid robots Walker S2 and autonomous mobile robots defines a new paradigm for autonomous logistics.

💰 Nomagic secures an additional $10M to accelerate commercial growth and advance its technology roadmap /NoMagic/

Business Transactions

This week’s top funding events, acquisitions, and partnerships across industrial value chains.

📑🌍 2025 Partech Africa Tech VC Report: African Tech Funding Rebounds to US$4.1B /Partech/

🌍 Dangote, China’s XCMG Seal Strategic Partnership On Infrastructure, Mining, Green Equipment /Independent Online/

🇺🇸🧠🏗️ Bedrock Robotics Raises $270 Million in Series B Funding to Accelerate the Future of Autonomous Construction

Bedrock Robotics, a leader in autonomous construction technology, announced it has raised $270 million in Series B funding co-led by CapitalG and the Valor Atreides AI Fund, with participation from Xora, 8VC, Eclipse, Emergence Capital, Perry Creek Capital, NVentures (NVIDIA’s venture capital arm), Tishman Speyer, Massachusetts Institute of Technology, Georgian, Incharge Capital, C4 Ventures, and others. This round brings Bedrock’s total funding to over $350 million. The funding will accelerate Bedrock’s mission to transform how general contractors build, from deploying individual autonomous machines to orchestrating fully connected fleets that reshape productivity and safety.

The industry needs nearly 800,000 workers over the next two years to keep up with demand, with retirements further widening the labor gap. Project backlogs climbed to more than eight months as of December 2025. Against this backdrop, contractors are exploring Bedrock’s autonomy systems across a range of applications spanning port infrastructure, industrial facilities, data centers, and large-scale earthmoving operations across multiple states. On a manufacturing campus in central Texas, Champion Site Prep is currently using the Bedrock Operator to explore how autonomous systems could complement the crews they have today.

Read more at PR Newswire

🇺🇸🖨️⚙️ VulcanForms Raises $220 Million in New Financing to Scale Its Leading U.S. Integrated Digital Metal Manufacturing Platform

VulcanForms, the company building the first fully integrated digital metal manufacturing platform in the United States, announced the close of an oversubscribed $220 million financing round led by Eclipse and 1789 Capital, with participation from Washington Harbour, Fontinalis, IEQ Capital, and others. The financing reflects growing demand for secure domestic production of next-generation metal products and reinforces VulcanForms’ role in strengthening critical American advanced manufacturing capability.

The capital supports the expansion of VulcanForms’ fully integrated manufacturing facilities. These facilities combine advanced metal additive manufacturing technologies, precision machining, automation, inspection, and proprietary AI-enabled software into a single end-to-end workflow. By compressing this supply chain into one integrated production system, VulcanForms reduces complexity, minimizes waste, lowers total system cost, and delivers finished, high-performance products at production scale with consistent quality and fully integrated, secure supply chains. The investment also enables continued execution of the company’s technology roadmap and R&D programs that strengthen the platform, advance the company’s materials portfolio, and support future capacity expansion.

Read more at PR Newswire

🇺🇸 Uptool Launches from Stealth with AI Platform to Accelerate U.S. Manufacturing /PR Newswire/ with its first product designed to eliminate a critical bottleneck for U.S. small and midsize (SMB) manufacturers, helping them quote 10 times faster and win more business.

🇺🇸🦾🧠 Machina Labs Raises $124 Million to Scale Manufacturing Infrastructure for Defense and Advanced Mobility

Machina Labs, a leader in advanced manufacturing and robotics, announced it has closed a Series C financing totaling $124 million and the development of its first large-scale Intelligent Factory. Woven Capital, Toyota’s growth-stage venture arm, Lockheed Martin Ventures, Balerion Space Ventures, and Strategic Development Fund (SDF) invested in the round.

A significant portion of the capital will be used to launch Machina Labs’ first large-scale Intelligent Factory in the U.S., a 200,000-square-foot, production-ready facility that will house up to 50 RoboCraftsman™ cells and produce thousands of complex structural assemblies annually for defense and aerospace customers.

Read more at Business Wire

🇫🇮🛜⚡ Willo secures €2.9M to commercialise alignment-free wireless power

Willo has raised a €2.9 million Pre-Seed round to accelerate the development of its wireless power system. While most wireless power systems depend on alignment or directionality, Willo has designed a system that keeps devices charging over the air even as they move and rotate. Willo’s ambition is to create a world without cables — across consumer devices, industrial systems, manufacturing, drones, and virtually any electrically powered hardware.

The company’s core technology builds on more than a decade of wireless power research led by Ha-Van. After earning his PhD in South Korea, he returned as a postdoctoral researcher focused on wireless power transfer.

Read more at Tech.eu

Looking for additional content? Paid subscribers get more stories delivered each week as part of Overcapacity!