Moore’s Law is Dead, Long Live Moore’s Law

The automotive industry has an exponentially growing demand for chips, while chip makers struggle with exponential process data growth

Gordon Moore’s 1965 forecast that the number of components on an integrated circuit would double every year until it reached an astonishing 65,000 by 1975 is the greatest technological prediction of the last half-century. When it proved correct in 1975, he revised what has become known as Moore’s Law to a doubling of transistors on a chip every two years.

Moore’s Law is the best-known industrial exponential phenomenon, and part of the inspiration for this publication. Upon hearing about the continued chip shortage disrupting automotive vehicle production, I decided to investigate. Two additional exponential phenomenon in the world of semiconductors were uncovered.

First, the automotive industry demand for chips is increasing at an exponential rate. Grand View Research forecasts a compound annual growth rate of 10.7% over the next 10 years ending 2025. This seems reasonable as chips are used in dozens of car subsystems from the powertrain and safety to infotainment accounting for over 30% of the cost of a vehicle. Semiconductor Engineering has an excellent piece on “Improving Automotive Electronic Hardware With SAE J3168”. This is quite timely as Tesla was asked to recall 158,000 vehicles for touchscreen failures as the 8GB eMMC NAND flash memory component wears out after it has been overwritten too many times.

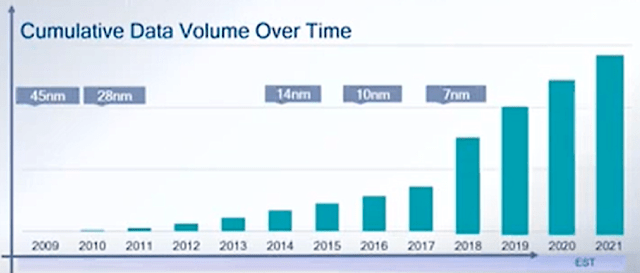

Additionally, the growth of semiconductor fabrication data has eclipsed engineers’ ability to analyze it. The collection of data within manufacturing environments has exploded but there is a critical shortage of engineers and scientists to makes sense of it well-enough to drive improvements back into the process. Partly, this is due to current machine learning and artificial intelligence algorithms inability to easily to encode physical, chemical, and biological constraints rendering state of the art algorithms useless to manufacturing engineers. This often leaves manufacturers with only one choice: store the data for a some future date in hopes the tools mature to make the data usable for future insights. But, this data storage and pipelining comes at considerable organizational burden and cost, just like having many external warehouses for housing spare inventory. As the Industry 4.0 data burden grows exponentially, we must figure out how store, analyze, and discard it more effectively or organizations will be overwhelmed very soon.

Video of the Week

Boston Dynamics viral video of its robots dancing to “Do You Love Me” has surely reached you by now. IEEE Spectrum’s Evan Ackerman discusses where Atlas got its moves from with Aaron Saunders, Boston Dynamics’ VP of Engineering.

How it Started vs How it’s Going

Credit: High Country News

Explore the history of U.S. railroads with FreightWaves. Nowadays, the U.S. struggles to get new rail projects started on both the East and West coasts. Asia continues to push the boundaries of rail technology with peak speeds of 620 km/h.

The Week in News

Designing the modern digital function

Date: January 8, 2021

To make digital industrial transformation a reality, a company needs both a nerve center and a dedicated digital function. Creating an operational structure is key, and this article suggests how leaders can make it happen.

Read more at Deloitte

Can a cobot offer the flexibility of a human on the shop floor?

Date: January 11, 2021

Since the Great Recession more than a decade ago, metal fabricators aren’t necessarily employing people unless they are absolutely needed. Manufacturing companies are lean, which helps to keep fixed costs down and the business more manageable when business slows.

It’s also a gamble. Unless shop floor personnel are cross-trained, the absence of a machine operator can sabotage productivity goals for the day. While more automated bending systems are being sold to North American fabricators, many shops still require an operator to sit in front of the press brake to get parts formed.

Read more at The Fabricator

Missing Chips Snarl Car Production at Factories Worldwide

Date: January 11, 2021

Semiconductor shortages may persist throughout the first half as chipmakers adjust their operations, researcher IHS Market predicted on Dec. 23. Automakers will start to see component supply gradually ease in the next two to three months, China Passenger Car Association, which groups the country’s largest carmakers, said Monday.

Chipmakers favor consumer-electronics customers because their orders are larger than those of automakers – the annual smartphone market alone is more than 1 billion devices, compared with fewer than 100 million cars. Automaking is also a lower-margin business, leaving manufacturers unwilling to bid up chip prices as they avoid risking their profitability.

Read more at Bloomberg

On Factory Floors, a Chime and Flashing Light to Maintain Distance

Date: January 12, 2021

Businesses like Henkel, a big German chemical company, are trying wearable sensors to prevent virus outbreaks among workers.

Read more at New York Times

Get ready for metamorphic manufacturing

Date: January 14, 2021

A new wrinkle in blacksmithing is hailed as the third wave of the industry’s digitization.

Metamorphic manufacturing, also known as robotic blacksmithing, is poised to bring about faster time to market, less material waste, more available materials, less energy used and more control.

Read more at SME

Surge Demand

Although NASA gives up on taking Mars’ temperature perhaps electron-beam 3D metal printing systems can help humanity overcome space exploration obstacles. Back on Earth, the robots continue to advance with an AI-powered vision system that improves pipe welding automation which doesn’t require constant operator supervision.