Laser in on Real Time Quality

In this week's digest printers build the largest carbon composite rocket structures, autonomous forklifts, ramp-up of battery production, and biologically inspired machine vision.

Shop Talk

Capturing this week's zeitgeist

Hyundai’s controversial Alabama plant is now driving its US growth. This week’s digest has a new (and hopefully less controversial) format to continue to drive subscriber and engagement growth to rival Factorio: Space Age.

We are building global supply chains, and Factorio makes a game out of that kind of thinking.

Tobias Lütke, co-founder and CEO of Shopify

Assembly Line

This week's most influential Industry 4.0 media.

🚀 3D printing ‘World’s Largest’ carbon composite rocket on Rocket Lab’s 90-ton 3D printer

✍️ Author: Alex Tyrer-Jones

🔖 Topics: Automated fiber placement

🏭 Vertical: Aerospace

🏢 Organizations: Rocket Lab

Californian space launch company Rocket Lab is using a 90-ton 3D printer to build what are said to be the ‘largest carbon composite rocket structures in history.’ The company’s 3D printer, a custom-built automated fiber placement (AFP) machine, is reportedly the biggest system of its kind in the world. Made in the United States by Electroimpact, the robotic 3D printer is 39 ft (12 meters) tall, and can lay down 328 ft (100 meters) of continuous carbon fiber composite per minute.

Rocket Lab has implemented the large-scale AFP machine at its Space Structures Complex in Middle River, Maryland. It is designed to automate the production of all major composite structures for the company’s reusable Neutron launch vehicle. These include panels for the 91-foot (28-meter) interstage and fairing, the 22.9-foot (7-meter) diameter first stage, and the 16.4-foot (5-meter) diameter second stage tanks.

According to Rocket Lab, while it takes several weeks to build a stage 2 dome using conventional, manual methods, the AFP machine can produce one in just 24 hours. The company anticipates it will save over 150,000 hours when constructing rocket structures with AFP technology.

Read more at 3D Printing Industry

More news in space manufacturing:

Redwire Announces Spaceflight Mission with Bristol Myers Squibb to Study Small Molecule Drug Compounds, Launching Additional Biopharma Investigations to Study Bone Disease Treatments in Space

🖨️ You can start with nothing and get to scale - The Rise of New Manufacturers

More news in additive manufacturing:

BMW goes bionic: A closer look at BMW's 3D printed robot grippers

🚛 Cyngn completes first paid DriveMod forklift deployment

🔖 Topics: Autonomous Forklift

🏢 Organizations: Cyngyn

Cyngn announced that its autonomous DriveMod Forklift has completed its first paid autonomous deployment at a customer facility. The Menlo Park, Calif.-based company said this marked a milestone in the commercialization of the next vehicle in its Enterprise Autonomy Suite, or EAS, portfolio. DriveMod has built-in safety features including 360° high-definition perception and Cyngn’s Virtual Bumper technology. The system is designed to navigate dynamic environments while attaining high operational precision safely, said the company.

Last month, Cyngn announced that OEM partner Motrec had built its first 12,000-lb. DriveMod Tugger. Last week, the company said that a major automotive equipment manufacturer is among the customers using the DriveMod Tugger. Cyngn also last week secured its 21st patent for a system and methods of adaptive object-based decision making for autonomous driving.

Read more at Automated Warehouse

More news in warehouse automation:

Vecna Robotics introduces CaseFlow automated case picking system

Vention’s Modular Conveyor Systems Built to Fit Any Production Line

The Power of Automation

🔋 Mastering Ramp-up of Battery Production

🔖 Topics: Manufacturing Line Commissioning

🏭 Vertical: Electrical Equipment

🏢 Organizations: RWTH Aachen University

The ramp-up phase of a gigafactory for the production of battery cells, modules and packs for electric mobility and other applications is crucial for its subsequent success. In the jointly published white paper “Mastering Ramp-up of Battery Production”, the Fraunhofer FFB and the Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University provide information on strategies and resources for an efficient and successful start-up of a gigafactory. The following figures illustrate the importance of this: according to the publication, scrap rates of 15 to 30 per cent in the first few years are common in battery cell production. Even after five years, however, scrap rates are still high at around ten per cent. Each percentage point costs around 30.000 € per day and around ten million euros per year. A rejection rate of 30 per cent at full capacity utilisation therefore means costs of around 900.000 € per day. It is a threat to the entire European electric mobility industry if local battery cell manufacturers are unable to increase their production capacities due to problems with factory ramp-up. The white paper therefore begins by outlining the organisational and technical hurdles associated with ramping up a gigafactory, and then offers insights into how these hurdles can be overcome and how the ramp-up process can be effectively managed.

Read more at Fraunhofer FFB

More news in battery manufacturing:

Festo Develops New Solutions for Automating EV Battery Manufacturing

Honeywell Revolutionizes Large-Scale Battery Manufacturing With Automation Software

Integrating SiMa.ai’s machine learning system on chip (MLSoC) technology with TRUMPF’s laser application expertise is expected to result in AI-optimized sensor technology that can monitor the quality of the laser welding process in real time and evaluate more than 3,000 images per second.

Mercedes-Benz opens own recycling factory to close the battery loop

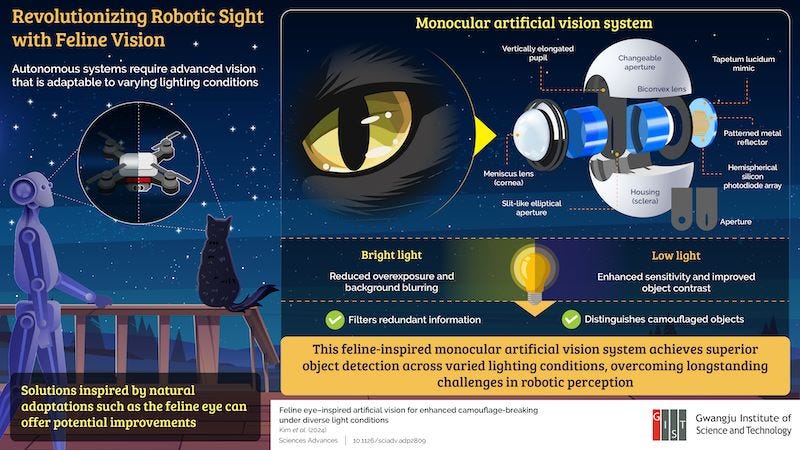

📷 Feline eye–inspired artificial vision for enhanced camouflage breaking under diverse light conditions

✍️ Authors: Min Su Kim, Min Seok Kim, Mincheol Lee

🏢 Organizations: Seoul National University, Gwangju Institute of Science and Technology

Biologically inspired artificial vision research has led to innovative robotic vision systems with low optical aberration, wide field of view, and compact form factor. However, challenges persist in object detection and recognition against complex backgrounds and varied lighting. Inspired by the feline eye, which features a vertically elongated pupil and tapetum lucidum, this study introduces an artificial vision system designed for superior object detection and recognition in a monocular framework. Using a slit-like elliptical aperture and a patterned metal reflector beneath a hemispherical silicon photodiode array, the system reduces excessive light and enhances photosensitivity. This design achieves clear focus under bright light and enhanced sensitivity in dim conditions. Theoretical and experimental analyses demonstrate the system’s ability to filter redundant information and detect camouflaged objects in diverse lighting, representing a substantial advancement in monocular camera technology and the potential of biomimicry in optical innovations.

Read more at Science Advances

More news in machine vision:

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

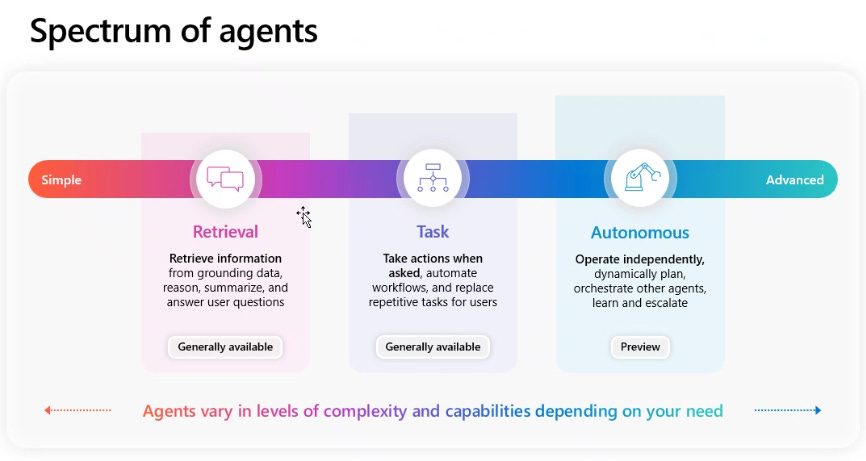

🧠 New autonomous agents scale your team like never before

🏢 Organizations: Microsoft

We’re introducing ten new autonomous agents in Dynamics 365 to build capacity for every sales, service, finance and supply chain team.

New autonomous agents enable customers to move from legacy lines of business applications to AI-first business process. AI is today’s ROI and tomorrow’s competitive edge. These new agents are designed to help every sales, service, finance and supply chain team drive business value — and are just the start. We will create many more agents in the coming year that will give customers the competitive advantage they need to future-proof their organization.

Read more at Microsoft Blogs

More news in generative AI:

🦾 PickNik Robotics’s Movelt Pro 6 Platform Brings Flexibility to Robotics

✍️ Author: Stephanie Leonida

🔖 Topics: Industrial Robot

🏢 Organizations: PickNik Robotics

PickNik Robotics (PR) unveiled its MoveIt Pro Release 6, the latest version of its flexible, open development platform for robotic applications spanning multiple industries. The hardware-agnostic, AI-driven system now has a true-to-life simulation engine for digital twins or virtual representations of physical assets and processes.

The Digital Twin technology employed by the Movlet Pro platform employs robot runtime algorithms in a true-to-life physics simulator. Users benefit from many reference applications, including bin-picking, welding/cutting, door opening (for facility access), preassembly and assembly, mobile manipulation, and more. Customers can also integrate the Movelt Pro Platform into fleet management platforms to provide a holistic view of operations.

Read more at Control Automation

🦾 Universal Robots unveils its AI Accelerator, enabling a new wave of AI-powered cobot innovations

🏢 Organizations: Universal Robots, NVIDIA, ORBBEC

Universal Robots, the Danish collaborative robot (cobot) company, presented for the first time the UR AI Accelerator – a ready-to-use hardware and software toolkit created to further enable the development of AI-powered cobot applications.

The toolkit brings AI acceleration to Universal Robots’ (UR) next-generation software platform PolyScope X and is powered by NVIDIA Isaac™ accelerated libraries and AI models, running on the NVIDIA Jetson AGX Orin™ system-on-module. Specifically, NVIDIA Isaac Manipulator gives developers the ability to bring accelerated performance and state-of-the-art AI technologies to their robotics solutions. The toolkit also includes the high-quality, newly developed Orbbec Gemini 335Lg 3D camera.

Read more at PRNewswire

More news in cobots:

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🚛 Outrider Closes $62 Million Series D Financing to Drive Growth of Yard Automation

🔖 Topics: Funding Event

🏢 Organizations: Outrider, Koch, New Enterprise Associates

Outrider, the leader in autonomous yard operations for logistics hubs, has raised $62 million in an oversubscribed Series D financing round. The round was led by Koch Disruptive Technologies (KDT) and New Enterprise Associates (NEA), with additional investments from 8VC, ARK Invest, B37 Ventures, FM Capital, Interwoven Ventures, NVentures (NVIDIA’s venture capital arm), and Prologis Ventures. This funding will drive the commercial scaling of Outrider’s autonomous yard operations as a service with Fortune 500 customers in 2025 and solidify its position at the forefront of logistics automation.

With over $250 million in equity capital raised to date, Outrider is working closely with customers to launch and scale autonomous yard operations as a service across industries such as package shipping, retail and eCommerce, consumer packaged goods, and automotive. Since 2019, Outrider’s customers, representing over 20 percent of all yard trucks in operation in North America, have been actively involved in product testing and pilot deployments, highlighting their commitment to reinventing yard operations.

Read more at PRNewswire-PRWeb

🚜 Carbon Robotics Raises $70 Million Series D Investment Round

🏢 Organizations: Carbon Robotics, BOND

Carbon Robotics, a leader in AI-powered farming, announced that it has raised $70 million in Series D financing. The financing was led by new investor BOND with participation from existing investors NVentures (NVIDIA’s venture capital arm), Anthos Capital, Fuse Venture Capital, Ignition Partners, Revolution, Sozo Ventures, and Voyager Capital. This round brings total company funding to $157 million. As part of the financing, Mood Rowghani, general partner at BOND, will join Carbon Robotics’ Board of Directors.

This new funding round will help scale Carbon Robotics’ LaserWeeder™ business, introduce new software and hardware products, and expand state-of-the-art manufacturing capabilities in Eastern Washington. It will also support the company’s growth in new markets and continue its geographic expansion into Eastern and Southern Europe, as well as the Asia-Pacific region.

Read more at Business Wire

📦 Nimble Closes $106 Million Series C Funding Round, Scales Fully Autonomous Fulfillment with FedEx

🏢 Organizations: Nimble, FedEx

Nimble, a pioneering AI robotics and autonomous e-commerce fulfillment technology company, announced the successful closure of a $106 million Series C funding round elevating the company to a $1 billion valuation.

The funding round was led by FedEx and co-led by existing shareholder Cedar Pine LLC. As part of their strategic alliance, FedEx has entered into a commercial agreement to scale its FedEx Fulfillment service using Nimble’s technology and fully autonomous 3PL model. The investment underscores FedEx’s confidence in Nimble’s groundbreaking technology and its commercial potential.

The new capital will be strategically deployed to scale robot manufacturing and system deployments while enabling further investments in R&D towards Nimble’s mission of inventing autonomous logistics.

Read more at Business Wire

📈 TwinThread & Timeseer.AI Form a Strategic Alliance to Deliver an AI-Powered Autonomous Solution for Industrial Companies

🔖 Topics: Partnership

🏢 Organizations: TwinThread, Timeseer AI

TwinThread and Timeseer.AI announce their strategic alliance that brings together two industry-leading platforms into an integrated solution that leverages AI and digital twins. Through this alliance, both companies aim to tackle two of the most pressing issues for industrial manufacturers: consistently extracting quality data from their operations and optimizing their manufacturing processes. Industrial manufacturers can, therefore, use this advanced technology to enhance operational efficiency and reach new heights in productivity.

Read more at TwinThread Press

🧑🏭 Epicor Acquires Acadia Software to Empower Frontline Workers

🔖 Topics: Acquisition

🏢 Organizations: Epicor, Acadia Software

Epicor, a global leader of industry-specific enterprise software to promote business growth, today announced it has acquired Acadia Software, a leader in Connected Worker solutions that provides real-time, actionable insights and step-by-step guidance directly to frontline workers in manufacturing and other supply chain industries. Financial terms were not disclosed.

By integrating Acadia’s capabilities, Epicor customers can empower their frontline teams to execute tasks with precision, providing them with real-time data, digital work instructions, and task management tools that contribute to continuous improvement across their organizations.

Read more at Business Wire

Battery scrap rates and production ramp up challenge is the single biggest bottleneck in the European battery industry. No Western company has managed to do it successfully yet. Asian players are good at it only because they started much earlier and managed to learn by trial when stakes were lower.