Inside the Best of Us Manufacturing

This week: industrial funding models (paid), K.I.S.S, America's Best, EV price wars, robotaxi value chains, titanium business model, native ERP AI Agents, quantum computing at scale.

Shop Talk

Capturing this week's zeitgeist

Manufacturing demands predictable outcomes, making the KISS principle essential for factory technology. The automation spectrum ranges from simple sensors to complex robotics, requiring solutions matched to specific problems rather than defaulting to sophisticated technology. While specialized machines costing hundreds of thousands excel at single high-volume tasks, emerging humanoid robots at lower price points could shift manufacturing toward smaller, more flexible production lines.

The KISS principle is best exemplified by the story of Johnson handing a team of design engineers a handful of tools, with the challenge that the jet aircraft they were designing must be repairable by an average mechanic in the field under combat conditions with only these tools. Hence, the "stupid" refers to the relationship between the way things break and the sophistication available to repair them.

If the average humanoid can repair another humanoid in the field, perhaps the future has arrived.

Assembly Line

This week's Industry 5.0 breakthroughs and frontier technologies of the built world.

⚙️🇺🇸 How SendCutSend Became America’s #1 Manufacturer

Read more on Twitter

🦾 A motion-first approach to smarter factory robots

Interesting Engineering (IE) spoke to Gokul N. A., the founder of CynLr, to understand how this approach differs from conventional robot vision and whether it can overcome the adaptation challenges that have limited industrial automation.

Even if the object is correctly identified, successful handling requires understanding not just “what the object is” but “how it can be physically handled.” The robot must determine where the object can be safely grasped, whether surfaces will slip or break under pressure, and how weight is distributed. None of this information can be reliably extracted from static images or color pattern analysis alone.

Read more at Interesting Engineering

RoboBallet: Planning for multirobot reaching with graph neural networks and reinforcement learning /Science Robotics/

🚙🇨🇳 Why China's electric car boom is losing money

Zoox plans for scalability with robotaxi serial production facility /The Robot Report/ and Robotaxi Value Chains: From Prediction to Reality /Evangelos Simoudis/

Polestar – the iPhone of EVs /FT/

Revolutionizing Automotive Materials: How WEAV3D is Transforming the Industry /YouTube/

DXC Advances AI Innovation in Automotive and Manufacturing through Startup Collaboration with with Acumino, CAMB.AI, and GreenMatterAI /PR Newswire/

🥛🇺🇸 Behind the Scenes at the Best Dairy Producer in the US

🧠⚗️ A new generative AI approach to predicting chemical reactions

Many attempts have been made to harness the power of new artificial intelligence and large language models (LLMs) to try to predict the outcomes of new chemical reactions. These have had limited success, in part because until now they have not been grounded in an understanding of fundamental physical principles, such as the laws of conservation of mass. Now, a team of researchers at MIT has come up with a way of incorporating these physical constraints on a reaction prediction model, and thus greatly improving the accuracy and reliability of its outputs.

Central to our understanding of chemical reactivity is the principle of mass conservation1, which is fundamental for ensuring physical consistency, balancing equations and guiding reaction design. However, data-driven computational models for tasks such as reaction product prediction rarely abide by this most basic constraint. Here we recast the problem of reaction prediction as a problem of electron redistribution using the modern deep generative framework of flow matching, explicitly conserving both mass and electrons through the bond-electron (BE) matrix representation. Our model, FlowER, overcomes limitations inherent in previous approaches by enforcing exact mass conservation, resolving hallucinatory failure modes, recovering mechanistic reaction sequences for unseen substrate scaffolds and generalizing effectively to out-of-domain reaction classes with extremely data-efficient fine-tuning. FlowER also enables downstream estimation of thermodynamic or kinetic feasibility and manifests a degree of chemical intuition in reaction prediction tasks. This inherently interpretable framework represents an important step in bridging the gap between predictive accuracy and mechanistic understanding in data-driven reaction outcome prediction.

Read more at MIT News and Nature

An offline-to-online reinforcement learning framework with trajectory-guided exploration for industrial process control /Journal of Process Control/

A novel self-generating abrasive jet machining process /Journal of Manufacturing Processes/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🪨🇦🇺 A platform technology for low-carbon cement makes progress

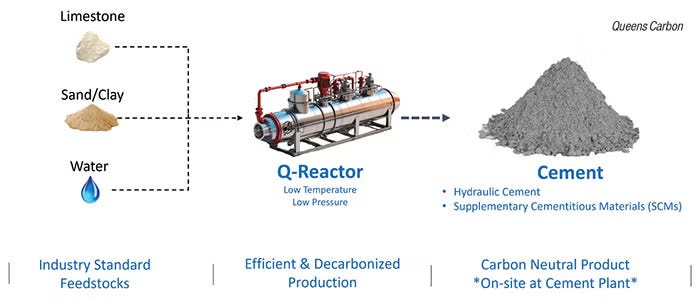

Two recent developments at Queens Carbon Inc., a spinoff company from Rutgers University, illustrate the potential for reducing the high carbon-dioxide emissions that result from cement and concrete production. Both are results of the company’s Q-System technology platform.

Read more at Chemical Engineering

Asahi Kasei electrolyzer system begins operations at Bondalti Chemicals chlor-alkali plant /Chemical Engineering/

🧠 Epicor Launches Industry’s First ERP AI Agent with Outcomes-Based Pricing to Accelerate Supplier Decisions

Epicor, a global leader of industry-specific enterprise software to promote business growth, today introduced Epicor Prism Business Communications, the industry’s first ERP AI agent with outcomes-based pricing. The solution automates RFQ workflows and accelerates supplier communications, helping supply chain businesses cut cycle time, reduce manual work, and make fast, confident purchasing decisions.

By streamlining manual workflows, improving quote accuracy, and accelerating purchasing decisions, Prism Business Communications delivers enhanced operational value. And, with an ERP industry-first in outcomes-based pricing for an AI agent, users only pay for RFQs that convert to purchase orders.

Read more at Business Wire

🪙🇺🇸 IperionX Accelerates U.S. Titanium Buildout

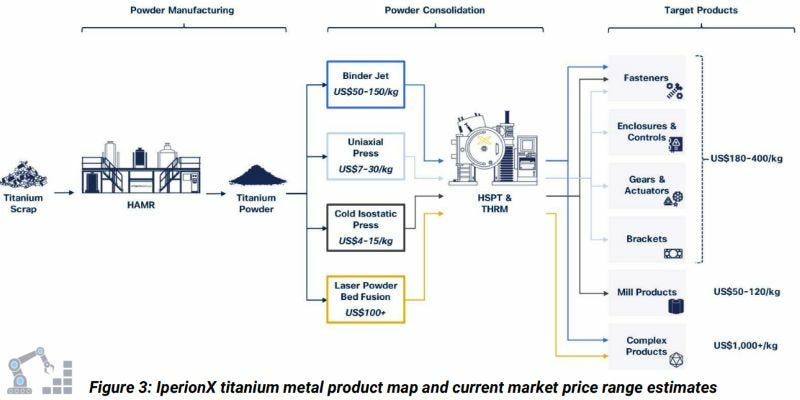

Anastasios (Taso) Arima, IperionX CEO said: “Our technology and process improvements at our Virginia Titanium Manufacturing Campus have lifted nameplate titanium powder capacity to 200 tpa - and laid the groundwork for a seven-fold scale-up in titanium production to 1,400 tpa in 2027. In parallel, we’re rapidly scaling our powder metallurgy, HSPT forging and additive systems to manufacture high-performance American-made titanium components. With a leading patented technology portfolio, we’re engineering a step-change reduction in the cost of manufacturing titanium components and building a fully integrated U.S.”

The seven-fold increase in titanium production capacity will target high-value, high ‘buy-to-fly’ ratio titanium components, in the form of near-net-shape and manufactured products, with a target market pricing range of $180/kg to $400/kg.

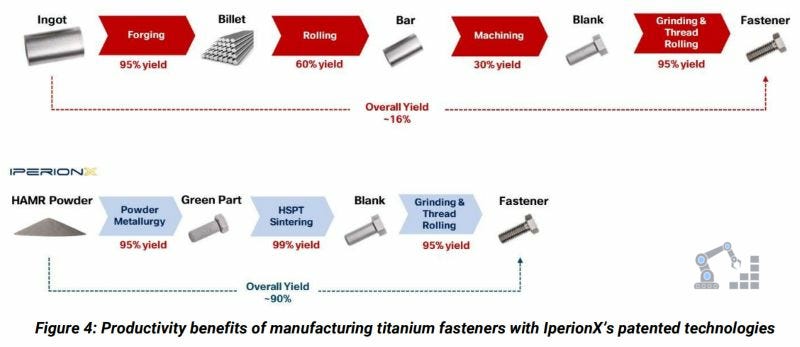

Fasteners — bolts, screws, nuts, washers, rivets — are ubiquitous across major U.S. markets in automotive, construction, aerospace, marine, and industrial machinery. Titanium fasteners represent a large addressable market for IperionX. Leveraging our integrated patented technologies and near-net-shape manufacturing, IperionX modeling indicates scope for product cost reductions of over 80%, and in some cases more than 90%, versus current market levels.

Read more at IperionX

💿🇰🇷 ASML and SK hynix assemble industry-first 'commercial' High-NA EUV system at fab in South Korea

SK hynix and ASML early on Wednesday announced that they had assembled the industry's first Twinscan NXE:5200B High-NA EUV lithography system at the company's fab M16 in Icheon, South Korea. The device will initially serve as a development vehicle for next-generation process technologies, but eventually it will be used for mass production of DRAM using leading-edge process technologies a few years down the line.

Read more at Tom's Hardware

Why memory chips are the new frontier of the AI revolution /FT/ and the hardware memory wall chokepoint /Rohan Paul on X/

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇺🇸 Honeywell Announces $600 Million Capital Raise for Quantinuum at $10B Pre-Money Equity Valuation to Advance Quantum Computing at Scale

Honeywell (NASDAQ: HON) announced an approximately $600 million equity capital raise for Quantinuum, developer of the world's highest-performing quantum computer, at a pre-money equity valuation of $10 billion. Quanta Computer, NVentures (NVIDIA's venture capital arm) and QED Investors have joined existing shareholders JPMorganChase, Mitsui, Amgen, Cambridge Quantum Holdings, Serendipity Capital and Honeywell — all of whom have reinvested in this round. The round also includes participation from new investors MESH and Korea Investment Partners.

This capital raise will support Quantinuum's advancement of quantum computing at scale, which includes continued progress toward the upcoming launch of Helios, the company's next generation quantum computing system that is expected to launch this year. It will also support Quantinuum's path to becoming the first to perform universal fault-tolerant computing.

Read more at PR Newswire

🇫🇮 IQM Quantum Computers Raises over $300 Million in Series B Funding Round Led by U.S. Investor Ten Eleven Ventures With Strong Support From Tesi /Business Wire/

🇬🇧 Phasecraft Raises $34 Million from Plural, Playground Global, and Novo Holdings to Bring Quantum Computing Closer to Solving Real-World Challenges /Business Wire/

🇺🇸🧠🚚 Augment Raises $85M Series A to Supercharge Augie, The AI Teammate for Logistics

Augment, the AI productivity platform for logistics, announced that it has raised $85 million in Series A funding, bringing its total capital raised to $110 million just five months after launching out of stealth. The round was led by Redpoint Ventures, with participation from 8VC, Shopify Ventures, Autotech Ventures, and other leading investors in logistics and AI.

This new capital will accelerate the development of Augie, Augment’s flagship AI teammate for logistics, and scale hiring across engineering and go-to-market functions. It will also power the rapid expansion of Augie into even more end-to-end logistics workflows for shippers, brokers, carriers, and distributors.

Read more at Business Wire

🇺🇸🧠📐 Leo AI has built an AI 'copilot' for mechanical engineers

Leo AI has created what it calls a large mechanical model, or "LMM," that's trained on engineering materials like sketches and peer-reviewed technical literature. Leo AI makes its money by offering a subscription model to clients, which includes Scania, HP, Siemens, and others.

Flint Capital led the $9.7 million seed round, which included participation from an A16z scout, Tech Aviv, Two Lanterns VC, and Google VP Yossi Matias, among others.

Read more at Business Insider

Want more? Check out the paid analysis and 100+ bonus reads below 👇