Hole-in-One Robots in Teaching and Metalforming

Trustworthy generative AI teaches robots 60 difficult, dexterous skills and metalforming. Digital twins can mimic the operations down to every tool, robot arm, and even the pace of human operators.

Shop Talk

Capturing this week's zeitgeist

“Manufacturing tolerances weren’t nearly as tight for golf balls [as they are today],” Parente said. “So [Spalding] had a robot down in Palm Desert — in the Palm Springs area — an old Iron Byron, and they told me they’d take 500 golf balls or 750 golf balls, at 110 mph, and they’d go out and take the balls that were plus or minus 30 yards greater right and left and discard them.

In celebration of Fanuc’s one-millionth robot and how far golf-ball manufacturing standards have come let’s celebrate with a robot hitting a hole-in-one!

Assembly Line

This week's most influential Industry 4.0 media.

Toyota Research Institute Unveils Breakthrough in Teaching Robots New Behaviors

📅 Date: September 19, 2023

🔖 Topics: Industrial Robot, Generative AI, Diffusion Policy

🏢 Organizations: Toyota

The Toyota Research Institute (TRI) announced a breakthrough generative AI approach based on Diffusion Policy to quickly and confidently teach robots new, dexterous skills. This advancement significantly improves robot utility and is a step towards building “Large Behavior Models (LBMs)” for robots, analogous to the Large Language Models (LLMs) that have recently revolutionized conversational AI.

TRI has already taught robots more than 60 difficult, dexterous skills using the new approach, including pouring liquids, using tools, and manipulating deformable objects. These achievements were realized without writing a single line of new code; the only change was supplying the robot with new data. Building on this success, TRI has set an ambitious target of teaching hundreds of new skills by the end of the year and 1,000 by the end of 2024.

Read more at Toyota Press

The treacherous path to trustworthy Generative AI for Industry

📅 Date: September 18, 2023

✍️ Author: Geir Engdahl

🔖 Topics: Generative AI, Large Language Model

🏢 Organizations: Cognite

Despite the awesome first impact ChatGPT showed and the already significant efficiency gain programming copilots are delivering to developers as users, making LLMs serve non-developers – the vast majority of the workforce, that is – by having LLMs translate from natural language prompts to API or database queries, expecting readily usable analytics outputs, is not quite so straightforward. Three primary challenges are:

Inconsistency of prompts to completions (no deterministic reproducibility between LLM inputs and outputs)

Nearly impossible to audit or explain LLM answers (once trained, LLMs are black boxes)

Coverage gap on niche domain areas that typically matter most to enterprise users (LLMs are trained on large corpora of internet data, heavily biased towards more generalist topics)

Read more at Cognite Blog

ROBOFORMING: The Future of Metalworking?

🏢 Organizations: Machina Labs

It Takes Two: Why Digital Twins Need Both Humans and Machines

📅 Date: September 19, 2023

✍️ Author: Ronni Shendar

🔖 Topics: Digital Twin, Facility Design

🏢 Organizations: Western Digital

When Western Digital expanded its hard drive manufacturing site in Thailand, the first time the assembly lines were turned on wasn’t on the factory floor; it was on a laptop 8,000 miles away. Before any physical machinery found its place within the newly constructed walls, teams of engineers meticulously crafted its virtual counterpart. This digital twin could mimic the operations down to every tool, robot arm, and even the pace of human operators, flawlessly simulating the assembly of the company’s most advanced enterprise hard drives. Engineers could quickly test different layouts and operation scenarios without touching the production line.

For most projects, Sanguanpong could go into the factory and measure parameters like cycle times, yield, output, or level of automation. Here, she needed to extrapolate data from experts about machines and processes that had yet to materialize. “Because there is no physical operation in the building, we the advanced analytics team needed to validate our findings with the subject matter experts, making sure our simulation model fit the expected action,” she said. Data needed to constantly flow in and out of the model, relying not only on algorithms but on the capacities of human communication and imagination.

Read more at Western Digital Blog

Your supplier’s supplier is not your supplier – Graph learning for transparency in deep-tier supply networks

📅 Date: September 19, 2023

✍️ Author: Qi Xiu

🔖 Topics: Graph Neural Network, Supply Chain Optimization

🏢 Organizations: Hitachi

Early graph neural networks have been applied to supply network data, but these are not as accurate as they could be because they focus only on supplier-buyer relationships and assume each company only produces one type of product. As a result, most companies with various types of products still lack visibility into risks involving deep-tier suppliers.

In this blog, we propose a graph representation learning method that models supply networks as heterogeneous graphs. The benefit of this model is that it can depict multiple relationships between companies and products, thus exposing the deep-tier supplier risk of companies with multiple products.

For companies within increasingly complicated supply networks, risk exposure extends far beyond direct suppliers. However, most companies lack risk transparency into their deep-tier supply networks because the supplier of their supplier is not their deep-tier supplier.

Read more at Industrial AI Blog

It’s arrived: Commoditization for industrial process control

📅 Date: September 19, 2023

✍️ Author: Josh Swanson

🔖 Topics: Edge Computing, Industrial Control System

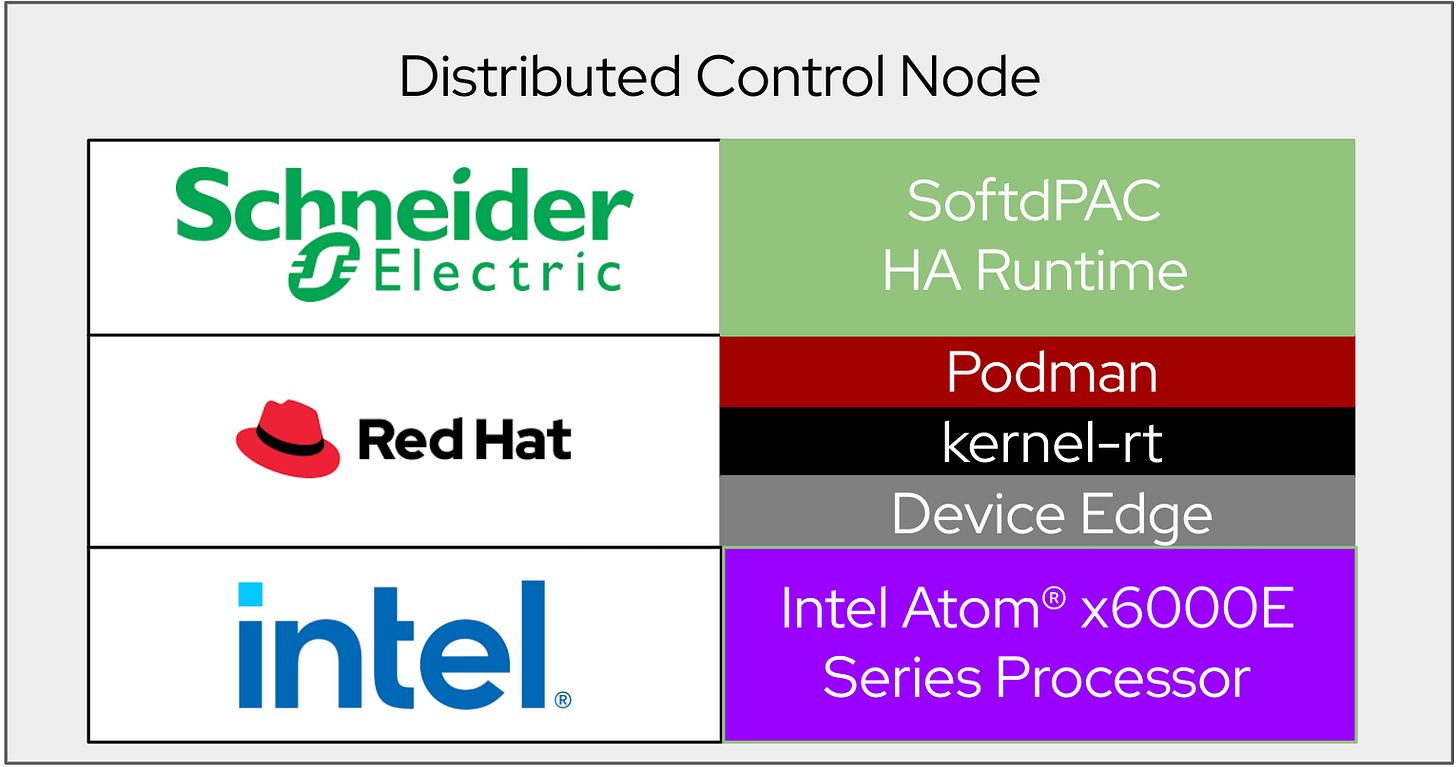

🏢 Organizations: Red Hat, Intel, Schneider Electric

With the advent of industrial process-control commoditization, technological advancements have expanded the boundaries of modern manufacturing–right to the computing edge. Traditionally, administrators had to walk out to a control system–USB stick in hand–and apply an update manually. Today, thanks to the combined work of Intel Corporation, Schneider Electric, and Red Hat, manufacturers can enjoy an edge-ready, software-defined, industrial control system that relieves the burden of manual effort and runs on commodity hardware and a commodity operating system and uses commodity automation techniques.

Read more at Red Hat

AI camera steers ships away from collisions in fog and darkness

📅 Date: September 23, 2023

✍️ Author: Keigo Yoshida

🏭 Vertical: Ship and Boat

Japanese trading company Marubeni is partnering with Israeli startup Orca AI to equip ships with artificial intelligence cameras that aid visibility in fog or darkness to reduce collisions. Orca AI’s camera system, dubbed SeaPod, has accumulated over 20 million nautical miles worth of marine visual data – equivalent to 4,200 transpacific trips between Japan and Los Angeles. The AI analyzes the big data from the footage, as well as from other parameters such as weather-related delays, to improve situational awareness of potential collisions.

Read more at Nikkei Asia

Industrial Policy

How governments are shaping the future industrial landscape.

🇮🇳 India plans over $2 billion in incentives for new manufacturing sectors

📅 Date: August 20, 2023

✍️ Authors: Shivangi Acharya, Sarita Chaganti Singh

India plans to offer incentives of up to 180 billion rupees ($2.2 billion) to spur local manufacturing in six new sectors including chemicals, shipping containers and vaccine inputs, two government officials said. The proposal is part of the country’s 1.97-trillion rupee production-linked incentive scheme (PLI), launched in 2020. It currently targets 14 sectors ranging from electronic products to drones but has succeeded only in a handful of them.

Read more at Reuters

🇺🇸 Arizona governor says state in talks with TSMC on advanced packaging

📅 Date: August 19, 2023

✍️ Author: Sarah Wu

Arizona is in talks with Taiwanese chipmaker TSMC on advanced packaging, Governor Katie Hobbs said on Tuesday, as the U.S. state seeks to attract more investment and address challenges that TSMC’s massive project has encountered there. TSMC is investing $40 billion to build two chip fabrication facilities, or fabs, in Arizona, supporting Washington’s plans to boost U.S. chipmaking capacity.

Read more at Reuters

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains

Dragos Raises an Additional $74M in Series D Round Extension

📅 Date: September 18, 2023

🔖 Topics: Funding Event

🏢 Organizations: Dragos, WestCap

Dragos, Inc., the global leader in cybersecurity for industrial controls systems (ICS)/operational technology (OT) environments, announced a $74 million Series D extension, led by strategic operating and investing firm WestCap.

The Series D funding extension will bolster Dragos’s ability to make ICS/OT cybersecurity more accessible around the world. This year, Dragos has already expanded across Western Europe and the DACH region, building on its established presence in the UK. This summer, Dragos entered into an agreement with Macnica to provide Dragos’s cybersecurity solutions in Japan, signifying Dragos’s expansion in Asia-Pacific beyond its presence in Australia and New Zealand.

Read more at Dragos Blog

Lumafield Announces $35M Series B Funding, Major Product Upgrades, and New Board Appointments

📅 Date: September 12, 2023

🔖 Topics: Funding Event

🏢 Organizations: Lumafield, Spark Capital, Lux Capital

Lumafield, a pioneering developer of accessible X-ray CT technology, today announced it has closed a $35M Series B funding round from new and existing investors, achieved a major new AI-driven performance breakthrough, and appointed two prominent executives to its board of directors. The company has raised a total of $67.5M to date, including a combined $32.5M in its Seed and Series A funding rounds. Spark Capital led the Series B round, which also included participation from existing investors Lux Capital, Kleiner Perkins, DCVC, and Future Shape.

Lumafield’s AI allows the company’s reconstruction process to achieve the same high-quality results with fewer two-dimensional X-ray images, reducing the time required to run a scan. New improvements in Lumafield’s software also make it possible to skip certain steps in the reconstruction process before performing automated analysis, which cuts processing time.

Read more at Lumafield Articles

Austrian firm Metaloop raises a €16M Series A for scrap metal recycling software

📅 Date: September 19, 2023=

The Austrian scrap metal marketplace, founded by Alexander Schlick and Jan Pannenbäcker, has just raised an oversubscribed Series A funding round of over €16 million. The funds will see the software firm source top talent to join its sales, recycling operations, product, data and development teams as it eyes further growth of its digital enterprise software platform.

The round was led by capital from the US as FirstMark Capital backed the metal recycling cause. The round also included participation by Silence VC and existing investors Statkraft Ventures and FJ Labs.

Read more at Tech EU

Boxbot Raises $12M Series A Led by Playground Global

📅 Date: September 18, 2023

🏢 Organizations: Boxbot, Playground Global, Maersk

Boxbot, the vertical automation solution that sorts and stores packages for last-mile carriers, announced today a $12 million Series A round, led by Playground Global. Maersk Growth (the venture arm of A.P. Moller), Toyota Ventures, Pear Ventures, and Artiman Ventures also participated in the round, which brings the company’s total funding to $29.5 million. The funds will be used to accelerate the company’s mission of enabling carriers to provide more efficient delivery experiences and bolster the team’s engineering and business operations. Playground Global Venture Partner Richard Peretz, former CFO at UPS, will join the company’s board of directors.

Boxbot transforms conveyors into intelligent, three-dimensional package handling systems. The platform can store, sort, and sequence size-agnostic, high throughput payloads while requiring a minimal physical footprint. Storage density is maximized by dynamically adapting the space required for each payload in real time. The system is designed for flexibility and can be easily installed in both new or existing facilities.

Read more at Business Wire