Foundational Industrial Minerals & Materials

This week: critical battery metals locally with no waste, electro-active parts by extrusion-based 3D printing, plant biofoundry, methane pyrolysis, and intelligent engineering tools remain hot.

Shop Talk

Capturing this week's zeitgeist

Last week, we discussed automation's market entry starting with consumer markets. We beat both the Wall Street Journal and Waymo (not really) to the trends in robotic massages and robotaxis during my visit to Phoenix two weeks ago. A critical component is that the autonomy must deliver an end-to-end service as Travis Kalanick explains his kitchen automation bowl builder. If Exponential Industry has helped you get an edge in your career or business please support the publication with a paid subscription. Our exclusive paid quarterly issue will drop end of July on top of weekly commentary at the end of each Sunday digest.

On tap this week is REINDUSTRIALIZE 2025 in Detroit, MI, July 16 and 17. If you're around the Metro Detroit area and want to connect, don't hesitate to reach out. Sebastian Völkl has put together a wonderful list of all the companies attending this year.

Assembly Line

This week's most influential Industry 4.0 media.

🔋 Aspiring Materials Produces Critical Battery Metals With No Waste

✍️ Author: Laurie Winkless

Aspiring Materials has developed a patented chemical process that produces multiple valuable minerals from olivine, leaving no harmful waste behind. Perhaps most interesting to the energy sector is the rarest of its products—hard-to-source nickel-manganese-cobalt hydroxide that is increasingly required for lithium-ion battery production.

Aspiring’s pilot plant, which opened in February, is in an anonymous industrial estate east of Christchurch, New Zealand. One corner of the main floor is dominated by a large stainless-steel tank, which is connected to a series of smaller tanks arranged in a stepped line. “Apart from our electrolysis system, the hardware is more typical of dairy plants,” says Colum Rice, Aspiring’s chief commercial officer. “The process is elegant but not massively complicated. Our inputs are rock, water, and renewable energy, and our products come with no CO2 emissions.”

Read more at IEEE Spectrum

Lignin-Based Separators for Lithium-Ion Batteries via a Dry Fibrillation Method /Advanced Materials/ extends EV battery life by 60%, withstands heat up to 572°F /Interesting Engineering/

Machine learning-assisted benign transformation of three zinc states in zinc ion batteries /Energy & Environmental Science/

Artificial Intelligence-Driven Development in Rechargeable Battery Materials: Progress, Challenges, and Future Perspectives /Advanced Functional Materials/

🚙 Exclusive Tour of Slate Auto’s Beta EV Factory + Interview with CEO & Lead Engineer

Visit of Slate's beta facility in Michigan and speak with several team members, including CEO Chris Barman and Head Engineer Eric Keipper. Munro explores how Slate is redefining affordable, reliable, and customizable electric vehicles and how they influenced some of their key decisions along the way.

Rivian Spinoff, Also Inc., Making Small EVs Valued at $1 Billion /Bloomberg/

Upstream report reveals 70% of US recalls could have been detected earlier using connected vehicle data /Telematics Wire/

📦 Boosting efficiency and productivity with AGVs by Vectra

How Visual Perception of Moving Machines is Revolutionizing Material Handling /RGo Robotics/

Honeywell To Evaluate Strategic Alternatives For Productivity Solutions And Services And Warehouse And Workflow Solutions Businesses /Honeywell/

Munich-based Filics secures €13.5M to bring space-saving robotics to more warehouses across Europe /Silicon Canals/

🖨️ Application of partially soluble filaments to build electro-active parts by extrusion-based 3D printing

Fused Filament Fabrication (FFF) has benefited from the emergence of partially water-soluble materials, enabling the creation of three-dimensional porous structures with varying void densities, pore sizes, and geometries. This development opens the possibility of using these materials to fabricate 3D chemical sensors by integrating 3D printing technology with partially water-soluble filaments coated with electro-conductive polymers, such as polyaniline (PANI). For this purpose, a filament based on Thermoplastic Elastomer (TPE) and Poly (vinyl alcohol) (PVA) from the Poro-Lay™ materials family was employed. The building process of electro-conductive porous parts involved 3D printing, followed by PVA extraction, PANI coating, and characterization at three stages: after printing, after PVA extraction, and after PANI coating. PANI was applied via in situ oxidative polymerization. The extraction of PVA resulted in a notable increase in porosity while maintaining a consistent and reproducible porous density. The PANI-coated samples exhibited electrical conductivity ranging from 0.39 to 6.79 S.cm−1. Eight different 3D printing parameter combinations were investigated for sensor applications using the Taguchi method. Results showed that part thickness and infill density were the most significant factors affecting sensor sensitivity. In a subsequent study, these parameters were optimized alongside PANI concentration. All prototypes demonstrated sensitivity to ammonia (NH₃), with lower thickness, infill density, and lower PANI concentration showing enhanced sensitivity, likely due to improved gas diffusion. This approach highlights the potential for creating high-performance, electro-responsive 3D-printed sensors for environmental monitoring and other applications.

Read more at Journal of Manufacturing Systems

Lenbach Equity Opportunities III (LEO III) acquires TRUMPF’s metal AM business /VoxelMatters/

Stratasys acquires select 3D printing assets from Nexa3D /TCT/

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

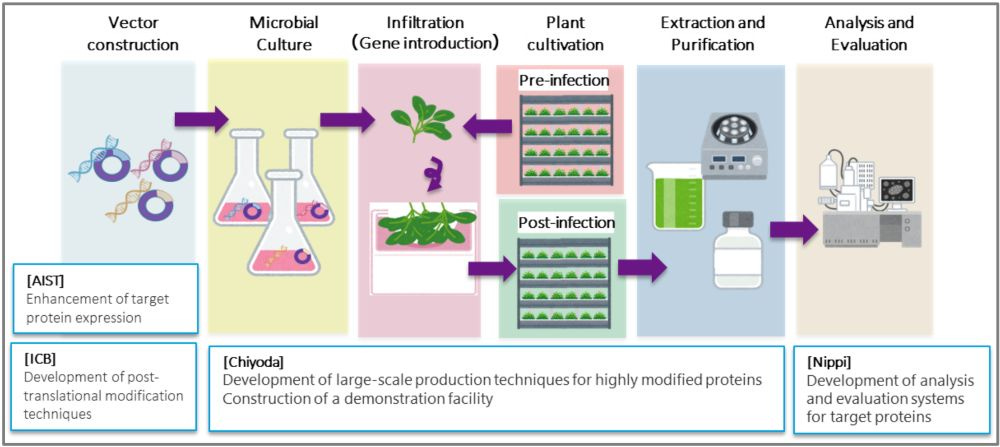

♻️🌿 Development of Large-scale Production Technology for Useful Proteins Using Plants

Chiyoda Corporation has successfully developed foundational technology for producing useful substances using plants, as part of NEDO's project 'Development of Bio-derived Product Production Technology to Accelerate Carbon Recycling'. The project demonstrates the production of human type II collagen, the first of its kind globally, as a model protein for the production of useful substances. Utilizing plants allows for animal-free and cost-effective production of products, such as vaccines, pharmaceuticals, regenerative medicine products, cosmetics and functional foods, while reducing greenhouse gas emissions.

This facility, Japan's first 'Plant Biofoundry', is dedicated to the practical development of plant bio-manufacturing and will support research and development from third party institutions and companies. This will be showcased at Chiyoda's booth during the 'INTERPHEX Week Tokyo / Regenerative Medicine EXPO Tokyo' held at Tokyo Big Sight from 9 to 11 July, 2025.

Read more at Chiyoda

♻️🚙 Six Companies Establish BlueRebirth Council to Expand Use of Recycled Materials in New Vehicles

DENSO CORPORATION, Toray Industries, Inc., Nomura Research Institute, Ltd., Honda Motor Co., Ltd., MATEC Inc., and REVER CORPORATION are pleased to announce the establishment of the BlueRebirth Council. Initiated by these six companies, the Council aims to build a manufacturing and recycling integrated value chain to realize Car-to-Car recycling, starting with automated precision dismantling, which efficiently disassembles end-of-life vehicles (ELVs) for material recovery and recycling.

Read more at WebWire

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

Activist investors target Japan’s chemical giants /C&EN/

🇺🇸🧑🔧 MaintainX Raises $150M to Transform Asset Management and Industrial Operations with AI

MaintainX, the leading maintenance and asset management platform, announces $150M in Series D funding. Key investors in this round include Bessemer Venture Partners, Bain Capital Ventures (BCV), D. E. Shaw Ventures, Amity Ventures, August Capital, Founders Circle Capital, Sozo Ventures, and Fifth Down Capital, as well as angel investors Rahul Mehta, co-founder of DST Global, and Dave McJannet, CEO of Hashicorp, among others. The new round of funding will allow MaintainX to expand its AI and machine health monitoring capabilities and partnerships, advance predictive maintenance solutions, and further develop enterprise asset management (EAM) capabilities. This investment brings the total raised to $254M while reaching a new valuation of $2.5B.

Read more at Business Wire

ServiceUp Raises $55 Million in Series B Funding to Transform Vehicle Repair Management /Business Wire/

Can a troubleshooting AI assistant improve task performance in industrial contexts? /International Journal of Production Research/

🇱🇺⚡Tulum Energy Secures $27 Million in Venture Financing to Rapidly Scale Groundbreaking Turquoise Hydrogen Technology

Tulum Energy, a pioneering methane pyrolysis startup, has successfully closed a $27 million venture financing round. This significant investment, led by CDP Venture Capital (through its Green Transition Fund) and TDK Ventures and a global consortium of prominent investors including Tulum’s founder TechEnergy Ventures, MITO Technology, through the MITO Tech Ventures fund, and Doral Energy Tech Ventures, underscores strong confidence in Tulum Energy's innovative approach to clean hydrogen production.

Tulum Energy is at the forefront of developing a revolutionary methane pyrolysis technology. Methane pyrolysis is a chemical process that consists in producing clean (turquoise) hydrogen and solid carbon using natural gas or biogas as a feedstock, without CO2 emissions. Methane Pyrolysis can overcome the economic and infrastructural limitations of green and blue hydrogen in the industrial production of decarbonized hydrogen. "The distinguishing feature of our technology is its unmatched combination of high scalability and exceptional energy efficiency," states Massimiliano Pieri, CEO of Tulum Energy. "This allows us to meet the substantial demands of large industrial consumers of hydrogen, such as refineries, ammonia producers, and chemical plants — at truly competitive costs, even without relying on tax credits and incentives."

Read more at Business Wire

Octopus Energy unleashes Kraken: £10bn spin-out set to disrupt global utility tech /TFN/

🇺🇸📐 Foundation EGI Secures $23M in Oversubscribed Series A to Build the World's First Engineering General Intelligence Platform

Foundation EGI, creator of the world's first Engineering General Intelligence (EGI) platform, announced $23M in oversubscribed Series A funding, raising over $30M total. The company is accelerating its vision of turning manufacturing's biggest bottlenecks into breakthroughs using domain-specific AI. The latest round was led by Translink Capital with participation from RRE Ventures, McRock Capital, Escape Investment Management (Jim Scapa), Fifth Growth Fund, and returning backers including E14 Fund, UNION, GRIDS Capital, and Henry Ford III.

Foundation EGI was born from MIT's cross-disciplinary research in AI for design and manufacturing, led by co-founders Matusik and Michael Foshey. Their seminal paper, Large Language Models for Design and Manufacturing, was published in 2024 and has influenced a new wave of intelligent engineering tools. Foundation EGI was founded to commercialize and power real-world AI applications for all manufacturing domains, including automotive, heavy industry, appliances, power tools, advanced manufacturing, and much more.

Read more at PR Newswire

Autodesk Weighs Takeover of Engineering Software Firm PTC /Bloomberg/

Industrial Foundation Models (IFMs) for intelligent manufacturing: A systematic review /Journal of Manufacturing Systems/

🇸🇬🦾 Augmentus Raises $11M to Scale Physical AI for High-Mix, Complex Robotic Surface Finishing and Welding

Augmentus, the developer of an intelligent no-code robotics solution, announced that it has raised USD $11 million (SGD $14 million) in a Series A+ funding round. The funds will be used to accelerate regional deployment of its fully autonomous robotic surface finishing and welding systems, fulfill demand from marquee manufacturing customers, and advance R&D into hyper-adaptive, AI-driven robotic systems built for the factory floor. The round was led by Woori VP, with participation from new investor EDBI, alongside returning backers Sierra Ventures and Cocoon Capital.

Read more at ACCESS Newswire and The Robot Report

RealSense Completes Spinout from Intel, Raises $50 Million to Accelerate AI-Powered Vision for Robotics and Biometrics /Business Wire/

🇺🇸💊 Synfini Adds $8.9 Million Discovery Funding to Speed Small Molecule Drug Development

Synfini, a trailblazer in AI-driven chemistry automation, announced a $8.9 million expansion of its round, led by JSL Health Capital and supported by a strong syndicate of early-stage investors. This brings Synfini’s total funding to $53 million, comprised of non-dilutive grants and venture investment. The company’s AI Cloud Foundry platform uniquely integrates artificial intelligence, automated synthesis, and iterative molecular design to dramatically accelerate small molecule drug discovery and synthesis. By combining physical and virtual chemistry in a unified workflow, Synfini delivers novel, high-quality pharmaceutically optimized compounds at unprecedented speed, while dramatically reducing costs.

Read more at GlobeNewswire

Varda Announces $187 million in Series C Funding to Make Medicines in Space /PR Newswire/

🇺🇸🪨 MP Materials Announces Transformational Public-Private Partnership with the Department of Defense to Accelerate U.S. Rare Earth Magnet Independence

MP Materials Corp. (NYSE: MP) announced it has entered into a transformational public-private partnership with the United States Department of Defense (“DoD”) to dramatically accelerate the build-out of an end-to-end U.S. rare earth magnet supply chain and reduce foreign dependency.

With a multibillion-dollar package of investments and long-term commitments from DoD, MP Materials will construct the Company’s second domestic magnet manufacturing facility (the “10X Facility”) at a soon-to-be-chosen location to serve both defense and commercial customers. Once the new facility is completed, expected to begin commissioning in 2028, MP Materials’ total U.S. rare earth magnet manufacturing capacity will reach an estimated 10,000 metric tons. The Company also expects to add additional heavy rare earth separation capabilities at its Mountain Pass, California, facility, solidifying its status as a national strategic asset where high-purity rare earth materials are extracted, separated and refined all in one location.

Read more at Business Wire

Ionic Mineral Technologies Closes Oversubscribed $29 Million Series B to Scale U.S. Production of Advanced Battery Materials /Business Wire/

Nth Cycle is bringing critical metals refining to the U.S. /MIT News/

Trump’s Africa Summit Heats Up Rivalry for Continent’s Resources /Bloomberg/

Want more? Check out the paid analysis delivered weekly below 👇