Faster Turnaround Times, Constraints, Time, and Money

The theory of constraints drives manufacturing decision-making with everything being a function of burn rate. Manufacturing technology founders train on popular video games.

Shop Talk

Capturing this week's zeitgeist

Not everything can be shipped economically, especially industrial goods. One Londoner figured out how to move an entire brewhouse from California to London.

A brewhouse—a four-vessel 50–beer barrel (50bbl) system that included six fermenters, brite beer tanks, water tanks, a gristmill and more

That reminded me of the time a few years ago, after a fire at one of their suppliers Ford had to use a huge plane to move 19 die tools to get their F-150 line back up and running. Also, Musk on the relationship between time and money.

On Twitter, games with the theory of constraints captivate the conversation:

I’d add the Kerbal Space Program and the Production Line Game to the mix.

Assembly Line

This week's most influential Industry 4.0 media.

Briquetting Manufacturer Tools Up for Faster Turnaround Times

✍️ Author: Nathaniel Fields

🔖 Topics: Machine Tool

🏢 Organizations: KR Komarek, Mazak, Ceratizit, Mastercam

With a wide variety of briquette designs, sizes and materials, machining these rolls is a demanding task for machine tools and, in particular, tooling. To overhaul a lengthy, hands-on process, Komarek paired a Mazak turn-mill machine with Ceratizit ISO-P-grade tooling to reduce production cycles and eliminate an arduous hand-grinding process.

Employees who formerly would have been tackling manual tasks on the briquetting roll production line can now work in Komarek’s reconditioning and repair department. These new processes also eliminated the potential for human error from hand-ground pockets, and by previewing milling paths through simulation features within Mastercam, Komarek is seeing less than a thousandth of an inch of variance in pockets. Tool life has also become much more predictable.

Read more at Modern Machine Shop

What Progress Has There Been In Industrial Robots?

✍️ Author: Brian Potter

🔖 Topics: Industrial Robot

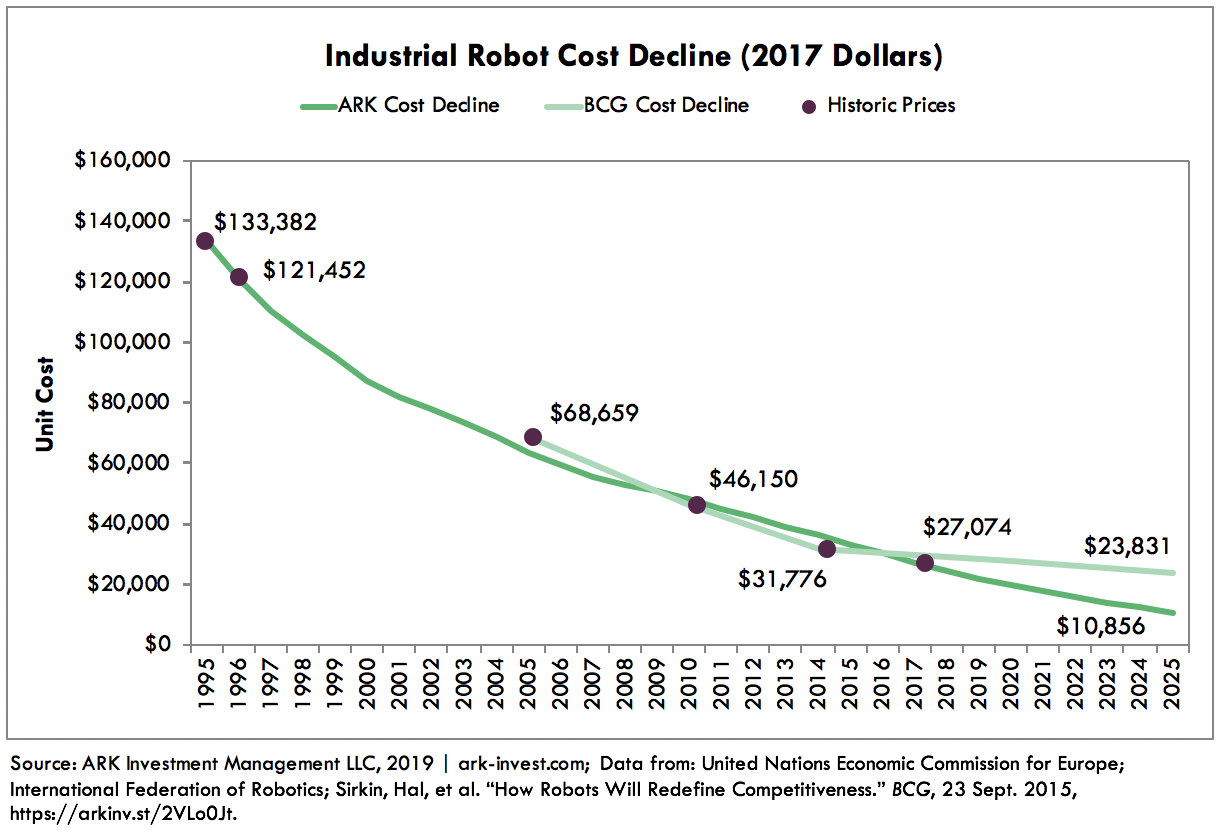

Robots, separated from the software and sensors that give them perception and intelligence, aren’t complex (conceptually at least). They’re a collection of control systems, motors, and gearboxes mounted to lever arms that make it possible to move things around in particular ways in 3D space. They can have different end effectors mounted to them for tasks like grasping, welding, or painting. One possible axis of improvement for robotic hardware is cost: if robots get cheaper over time, it becomes possible to cost-effectively use them in more locations.

So, overall, robots have fallen substantially in cost since the 1980s, while simultaneously getting more precise. A robot with a 1-meter reach and 10 kg payload capacity would cost anywhere from 2 to 3 times as much in the 1980s as it does today, even before considering the rise of cheap Chinese robot arms, which seem poised to make prices fall even more. And the modern industrial robot is roughly 100 times more accurate, and far more capable at smooth, continuous motion, than robots in the past.

Read more at Construction Physics

NJM turnkey integrated solid dose line

The Future of Robotics: Robotics Foundation Models and the Role of Data

✍️ Author: Peter Chen

🔖 Topics: Industrial Robot, AI

🏢 Organizations: Covariant

Covariant’s robotics foundation model relies on vast amounts of “warehouse-scale” real-world data and synthetic data. General image data, paired with text data, is used to help the model learn a foundational semantic understanding of the visual world. Real-world warehouse production data, augmented with simulation data, is used to refine its understanding of specific tasks needed in warehouse operations, such as object identification, 3D understanding, grasp prediction, and place prediction.

Read more at Covariant Resources

DiffuseBot: Breeding Soft Robots With Physics-Augmented Generative Diffusion Models

✍️ Authors: Tsun-Hsuan Wang, Juntian Zheng, Pingchuan Ma

🏢 Organizations: MIT, Tsinghua University

Nature evolves creatures with a high complexity of morphological and behavioral intelligence, meanwhile computational methods lag in approaching that diversity and efficacy. Co-optimization of artificial creatures’ morphology and control in silico shows promise for applications in physical soft robotics and virtual character creation; such approaches, however, require developing new learning algorithms that can reason about function atop pure structure. In this paper, we present DiffuseBot, a physics-augmented diffusion model that generates soft robot morphologies capable of excelling in a wide spectrum of tasks.

Read more at Open Review

How an ASML Lithography Machine Moves a Wafer

🏢 Organizations: ASML

Zortrax 3D Printers Used for Manufacturing of BMW Car Parts

🔖 Topics: Additive Manufacturing

🏢 Organizations: Zortrax, BMW

Here’s a story of how Krzysztof Urban, an engineer and Zortrax employee, used Zortrax 3D printers to restore his 2006 BMW e91 330d car.

Due to the high quality of both 3D printers and materials, the parts did not require much post-processing. The engineer just used a mini grinder to smooth the 3D prints only where necessary. He then painted the elements with black structural spray paint, choosing such techniques of applying the paint to achieve a structure like that of the factory elements.

Read more at Zortrax Blog

Discoveries in weeks, not years: How AI and high-performance computing are speeding up scientific discovery

🔖 Topics: Materials Science

🏢 Organizations: Microsoft, Pacific Northwest National Laboratory

Scientists at PNNL are testing a new battery material that was found in a matter of weeks, not years, as part of the collaboration with Microsoft to use advanced AI and high-performance computing (HPC), a type of cloud-based computing that combines large numbers of computers to solve complex scientific and mathematical tasks.

As part of this effort, the Microsoft Quantum team used AI to identify around 500,000 stable materials in the space of a few days. The new battery material came out of a collaboration using Microsoft’s Azure Quantum Elements to winnow 32 million potential inorganic materials to 18 promising candidates that could be used in battery development in just 80 hours.

Read more at Microsoft News

New Product Introduction

Highlighting new and innovative products and services

Epson’s Latest High-Power-Density GX-B Series SCARA Robots Designed to Revolutionize Automation Now Available

🏢 Organizations: Epson

Offering multiple arm configurations, handle payloads up to 10 and 20 kg, high throughput and high payloads, the GX10B and GX20B’s versatile features empower machine builders to conquer challenging applications with leading-edge precision. The GX10B and GX20B are now available through Epson Robots’ channel of distributor partners.

Read more at Epson News

Doosan Robotics Unveils Cutting-Edge Innovations at CES 2024

🏢 Organizations: Doosan

Driving Doosan Robotics’ versatility within the robotics field is its introduction of Dart-Suite, a next generation robot ecosystem redefining the robot experience. Utilizing Integrated Development Environment (IDE), Dart-Suite allows consumers to create modules tailored to their needs, much like mobile device apps. The robust software platform dramatically reduces the development time by up to 80%. Working with Dart-Suite is comparable to the ease and usability of smartphones, shaping the user experience for a new era of robotics.

Read more at PR Newswire

Unleashing the Power of a Vendor-Agnostic Configurator and Immersive CX with Configit Ace®, Integrating with NVIDIA Omniverse

✍️ Author: Henrik Reif Andersen

🏢 Organizations: ConfigIt, NVIDIA

By choosing a vendor-agnostic configuration solution like Configit Ace®, which frees the product configurator from the CPQ bundle, manufacturers can not only expand their role to include unassisted sales channels such as websites and dealer portals, but also scale their manufacturing and engineering operations through a centralized hub of accurate, up-to-date configuration data.

With NVIDIA Omniverse, a platform for developing and deploying advanced 3D applications and pipelines based on OpenUSD, manufacturers across industries can deliver hyper-realistic simulations for an immersive 3D buying experience.

Read more at ConfigIt Blog

AI Augments Injection Molding Process Control System

RJG Inc. has announced a new feature for its CoPilot process control system called MAX, the process advisor. MAX uses advanced, AI technology powered by Master Molder techniques to provide molders with real-time, expert guidance to optimize their injection molding processes, including reducing waste during production and assisting in bridging the skills gap.

Read more at Moldmaking Technology

Industrial Policy

How governments are shaping the future industrial landscape.

🇲🇽 Air Liquide Pushes Mexico for Answers After Government Seizes Hydrogen Plant

✍️ Authors: Scott Squires, Amy Stillman

French industrial gas manufacturer Air Liquide is pressing Mexico for answers after the government took over operations at a hydrogen processing plant in Hidalgo state. Mexico ordered the temporary occupation of Air Liquide’s hydrogen plant at the Miguel Hidalgo refinery in the town of Tula on Dec. 29. The plant will be operated by Pemex’s refining arm known as Pemex Transformación Industrial, which will be responsible for paying compensation to the Paris-based company.

Read more at Bloomberg

🇹🇼 TSMC and PSMC Face Dilemma as Overseas Foundry Costs Skyrocket 2.5 to 4 Times

PSMC Chairman Frank Huang pointed out that, based on the data they have, the cost of building a fab in Japan is 1.5 times higher than in Taiwan, with construction costs being 2.5 times higher and operational costs 50% more expensive than in Taiwan. It would take 7 to 8 years for the combined construction and operation to become profitable, meaning the factory would only start making money three years after its establishment.

PSMC had already disclosed plans to assist India in technology transfer for building a fab in early 2023. Huang explained that because South Korea and the United States are unwilling to teach others how to make semiconductors, neither TSMC nor UMC are offering such assistance, leaving PSMC as the go-to option for those seeking guidance in semiconductor manufacturing.

Read more at Trend Force

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains

Resynergi Raises $6.4M in Series B Funding Co-led By Transitions First and Lummus Technology To Scale Plastic Recycling Technology

🔖 Topics: Funding Event

Resynergi, a pioneering leader in plastic recycling technology, announced it has raised $6.4M in series B funding co-led by Transitions First (T1ST), an international industrial deep tech seed-stage venture capital fund, and Lummus Technology, a global provider of process technologies and value-driven energy solutions. The funding will allow the company to scale production of its modular Continuous Microwave Assisted Pyrolysis (CMAP) technology that converts plastic waste into reusable materials at a rate 20 times faster than traditional pyrolysis methods. The company also plans to expand its executive team to drive growth and further cement the company’s position as a leader in plastic circularity.

Read more at PR Newswire

Xaba Closes $2 Million Seed Extension to Deliver Intelligent, Self-programming Robotic Systems for Manufacturing

🏢 Organizations: Xaba, BDC Capital, Hitachi

Xaba, developer of the first AI-powered cognitive software solution to automate programming and deployment of robotics and CNC machines, announced it has raised US$2 million in a seed extension round of funding to bring to market AI-driven fabrication processes and intelligent autonomous machines. The funding round was led by BDC Capital’s Deep Tech Venture Fund with participation from Hitachi Ventures and existing investor Hazelview Ventures. The investment will be used to establish and staff a new robotics lab and accelerate the delivery of two Xaba manufacturing platforms.

Xaba is augmenting industrial robots and cobots with xCognition, an artificial intelligence (AI)-powered software solution. xCognition leverages innovative proprietary ML algorithms to model the elasto-mechanical-dynamic behavior of industrial robotics and cobots, as well as workpiece variances.

Read more at Business Wire

N-ink wins €1M from Voima Ventures Science Challenge for its IoT-transforming conductive polymers

Swedish deep technology company N-ink was announced as the winner of a science challenge by Voima Ventures, an early-stage investor based in Helsinki and Stockholm. N-ink was founded in 2020 by scientists at the Laboratory of Organic Electronics, Linköping University in Sweden.

The company provides high-performing, scalable conductive polymers that boost battery and solar cell performance and are useful in Printed Electronics, IoT and Bioelectronics. N-Ink addresses this challenge by formulating and supplying n-type inks with unprecedented performance. Its patented n-Inks are highly conductive, easy to handle, stable, printable, and on par with commercial p-type inks.

Read more at Tech EU

ABB acquires Sevensense, expanding leadership in next-generation AI-enabled mobile robotics

🔖 Topics: Acquisition

🏢 Organizations: ABB, Sevensense, ETH Zurich

ABB announced that it has acquired Swiss start-up Sevensense, a leading provider of AI-enabled 3D vision navigation technology for autonomous mobile robots (AMRs). Sevensense was founded in 2018 as a spin-off from Swiss technical University, ETH Zurich.

Sevensense’s pioneering navigation technology combines AI and 3D vision, enabling AMRs to make intelligent decisions, differentiating between fixed and mobile objects in dynamic environments.

Read more at ABB News

Valiant TMS and Realtime Robotics Partner to Reduce a Customer's Cycle Time by 17% and Cut Programming Time in Half

🔖 Topics: Partnership

🏢 Organizations: Valiant TMS, Realtime Robotics

Realtime Robotics, the leader in collision-free autonomous motion planning for industrial robots, today announced that Valiant TMS, a full-service Industry 4.0 system integrator, has partnered with the company to apply its innovative Optimization-as-a-Service solution to customers’ manufacturing operations.

Read more at Business Wire

Siemens and Voltaiq collaborate to optimize battery manufacturing

🏢 Organizations: Siemens, Voltaiq

The joint solution addresses the challenges faced in the critical finishing stage of battery production – which makes up a significant portion of production costs and time – by helping to reduce the risk associated with discovering problems late in the production cycle where yield and profitability are most likely to suffer.

Read more at Voltaiq Blog