Engineering Virtual Assistants and Captivated By Gigacasting

Specialized large language models are incorporated into virtual assistants at NVIDIA and RoboDK. Gigacasting economics explained and the evolution from aluminum to magnesium has captivated analysts.

Shop Talk

Capturing this week's zeitgeist

While the rest of automotive industry is still figuring out how to incorporate gigacasting aluminum (see more below), magnesium casting is now off to the races.

Assembly Line

This week's most influential Industry 4.0 media.

Silicon Volley: Designers Tap Generative AI for a Chip Assist

📅 Date: October 30, 2023

✍️ Author: Rick Merritt

🔖 Topics: Generative AI, Large Language Model

🏭 Vertical: Semiconductor

🏢 Organizations: NVIDIA

The work demonstrates how companies in highly specialized fields can train large language models (LLMs) on their internal data to build assistants that increase productivity.

The paper details how NVIDIA engineers created for their internal use a custom LLM, called ChipNeMo, trained on the company’s internal data to generate and optimize software and assist human designers. Long term, engineers hope to apply generative AI to each stage of chip design, potentially reaping significant gains in overall productivity, said Ren, whose career spans more than 20 years in EDA. After surveying NVIDIA engineers for possible use cases, the research team chose three to start: a chatbot, a code generator and an analysis tool.

On chip-design tasks, custom ChipNeMo models with as few as 13 billion parameters match or exceed performance of even much larger general-purpose LLMs like LLaMA2 with 70 billion parameters. In some use cases, ChipNeMo models were dramatically better.

Read more at NVIDIA Blog

Unleashing the Potential of Large Language Models in Robotics: RoboDK’s Virtual Assistant

📅 Date: November 1, 2023

🔖 Topics: Generative AI, Large Language Model

🏢 Organizations: RoboDK

The RoboDK Virtual Assistant is the first step towards a comprehensive generalized assistant for RoboDK. At its core is OpenAI’s GPT3.5-turbo-0613 model. The model is provided with additional context about RoboDK in the form of an indexed database containing the RoboDK website, documentation, forum threads, blog posts, and more. The indexing process is done with LlamaIndex, a specialized data framework designed for this purpose. Thanks to this integration, the Virtual Assistant can swiftly provide valuable technical support to over 75% of user queries on the RoboDK forum, reducing the time spent searching through the website and documentation via manual methods. Users can expect to have an answer to their question in 5 seconds or less.

Read more at RoboDK Blog

Gigacasting: The hottest trend in car manufacturing

📅 Date: November 1, 2023

✍️ Authors: Edwin Pope, Mengyin Tao

🏭 Vertical: Automotive

🏢 Organizations: Tesla, IDRA Group

Gigacasting is all the rage in automotive manufacturing circles. And while Tesla has mainstreamed the term — involving enormous, high-pressure aluminum die casting machines that punch out vehicle chassis and bodies-in-white — the technology has largely caught on in mainland China. Now other automakers, including Toyota, are eyeing the process.

These massive gigacastings (also known as megacastings) carry huge initial startup costs, may have distortion issues in the metal, alter collision-repair capabilities, and require extensive end-of-line inspection scanning. And that is only after ordering a custom-built gargantuan piece of equipment, moving it into place, and figuring out how to efficiently work the temperamental processes. The cost-benefit analysis of gigacasting should be based on achieving a good-enough first-pass yield rate and maintaining a sufficient, yet not excessive, number of orders for the same part. When comparing gigacasting to conventional steel stamping or aluminum-stitching, S&P Global Mobility nonetheless assesses the unit price for a single-piece, gigacasted aluminum rear floor to be valid.

Read more at S&P Global Mobility Blog

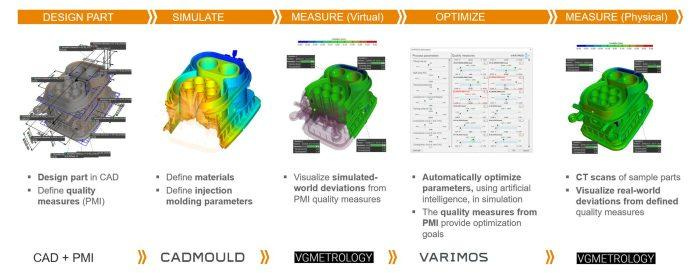

How CT Data Analysis is helping TE Connectivity Reach Their Ultimate Goal of End-to-End Quality Inspection

📅 Date: November 1, 2023

🏢 Organizations: TE Connectivity, Volume Graphics

As impressive as interconnected digital-platform benefits are for traditional CAD/CAE/CAM disciplines, Computed Tomography (CT)-data analysis for quality inspection has greatly expanded its reach and purpose within today’s growing digital landscape. Its new influence on the central tools of design, simulation and manufacturing are significant; CT data analysis software is making these tools, normally used well upstream of it, even better in their roles.

“We are on target for a ten-day turnaround for design, simulation, scanning and producing a digital metrology report,” says Stokowski. “So much is now going on upfront. We want as much done as possible before we hold a physical part.” Volume Graphics has helped TE Connectivity in this frontloading and looping of data with their Adaptive Measurement Templates. The templates can classify, localize and segment defects using AI and Machine Learning. They also automate much of the scan analysis and then capture information for metrology reports. The goal at TE Connectivity is to lower analysis time from 10 days to five.

Read more at Industrial Machinery Digest

Adopting open-source Industrial IoT software

📅 Date: November 1, 2023

✍️ Author: Edoardo Barbieri

🔖 Topics: IIoT, IT OT Convergence, Open Source

🏢 Organizations: Ubuntu

To fully reap the benefits of Industry 4.0, the industrial factory has to close the gaps between Operational Technology (OT) and IT. The convergence between the two domains calls for a transition from legacy stacks with closed standards and interfaces to modern IT solutions and the embrace of open-source software.

Read more at Ubuntu Blog

Automate plant maintenance using MDE with ABAP SDK for Google Cloud

📅 Date: October 31, 2023

✍️ Authors: Manas Srivastava, Devesh Singh

🔖 Topics: Manufacturing Analytics, Cloud Computing, Data Architecture

🏢 Organizations: Google, SAP, Litmus

Analyzing production data at scale for huge datasets is always a challenge, especially when there’s data from multiple production facilities involved with thousands of assets in production pipelines. To help solve this challenge, our Manufacturing Data Engine is designed to help manufacturers manage end-to-end shop floor business processes.

Manufacturing Data Engine (MDE) is a scalable solution that accelerates, simplifies, and enhances the ingestion, processing, contextualization, storage, and usage of manufacturing data for monitoring, analytical, and machine learning use cases. This suite of components can help manufacturers accelerate their transformation with Google Cloud’s analytics and AI capabilities.

Read more at Google Cloud Blog

Powering Up the Industrial Metaverse

Development of ultra-fast computing method for powder mixing process

📅 Date: October 6, 2023

✍️ Authors: Naoki Kishida, Hideya Nakamura, Shuji Ohsaki, Satoru Watano

🏭 Vertical: Chemical

Powder mixing is an important operation in many industries. Numerical simulations using the discrete element method (DEM) have been widely used to analyze powder-mixing processes. However, one of the current limitations of the DEM simulation is its high computational cost. Recently, approaches that combine machine learning models and numerical simulations have attracted considerable attention for high-speed computing. However, there has been no research on high-speed computing methods for powder mixing that account for individual particle motions. Here, we propose an original machine learning model, namely, a recurrent neural network with stochastically calculated random motion (RNNSR), which enables a long-time-scale powder mixing simulation with low computational cost and high accuracy.

Read more at Chemical Engineering Journal

Industrial Policy

How governments are shaping the future industrial landscape.

🇩🇪 Siemens Energy Moves for State Backing in Wind Debacle

📅 Date: October 26, 2023

✍️ Authors: Wilfried Eckl-Dorna, Petra Sorge

Siemens Energy AG is in talks with the German government about securing as much as €16 billion ($16.9 billion) in state guarantees as problems at its wind-turbine unit spread to the rest of the business. Shares plummeted 40%.

Siemens Energy needs the guarantees to win new large-scale contracts to build transmission networks and gas turbines. While those units are profitable, they’re now threatened by the strain that the string of losses from the Gamesa wind unit is putting on the company’s balance sheet in what has become one of Germany’s biggest industrial debacles.

Read more at Bloomberg

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains

Seurat Technologies Raises $99M to Deploy Local Printing Factories, Decarbonize Manufacturing

📅 Date: October 30, 2023

🔖 Topics: Funding Event

🏢 Organizations: Seurat Technologies, NVIDIA, Honda

Seurat Technologies, the 3D metal printing leader that is making manufacturing better for people and the planet, today announced a $99 million Series C round led by NVentures, NVIDIA’s venture capital arm and Capricorn’s Technology Impact Fund focused on climate solutions. Seurat’s latest funding round includes participation from new investors Honda Motor and Cubit Capital, among others, as well as participation from previous investors, True Ventures, SIP Global Partners, Porsche Automobil Holding SE, Denso Global, General Motors Ventures, Maniv Mobility LP, and Xerox Ventures.

Powered by 100% green energy, Seurat is reinventing and reshoring manufacturing with its Area Printing technology developed at Lawrence Livermore National Laboratory. This 3D metal printing technology delivers high-precision, high-volume, decarbonized manufacturing, which Seurat anticipates will have the potential to directly mitigate as much as 100 million tons of CO2 by 2030.

Read more at PR Newswire

Aclarity Secures $16M in Series A Funding to Deploy Low Energy PFAS 'Forever Chemical' Destruction Solution

📅 Date: November 2, 2023

Aclarity, Inc., the leader in PFAS (Per- and Polyfluoroalkyl Substances) “forever chemical” destruction, announced today the successful completion of its Series A funding round, raising $15.9 million. This funding round was led by Aqualateral, with participation from HG Ventures, Bidra Innovation Ventures, Nor’easter Ventures, MassVentures, and Burnt Island Ventures. Over the last year, Aclarity has deployed mobile systems with full-scale reactors across the country to destroy PFAS chemicals continuously. This has allowed the team to successfully treat PFAS in waters ranging from low ng/Ls in tap water, all the way to landfill leachate treated by foam fractionation with PFAS concentrations of milligrams per liter, including short-chain compounds like PFBS and demonstrating real time PFAS destruction in the field.

Read more at PR Newswire

Flexport buys Convoy’s tech

📅 Date: November 1, 2023

🔖 Topics: Acquisition

🏢 Organizations: Flexport, Convoy

Freight company Flexport has acquired technology and a few dozen employees from Convoy, the one-time giant of the Seattle startup world that abruptly shut down last month. “We’ve acquired Convoy’s technology stack and are planning to retain a small group of team members from their core product and engineering team,” Flexport CEO Ryan Petersen wrote in a memo. “We are not acquiring Convoy the company or any of its liabilities and our expenses will be limited to what’s necessary to maintain the tech.”

Read more at GeekWire

Solugen and ADM Announce Strategic Partnership

📅 Date: October 30, 2023

🔖 Topics: Partnership

🏢 Organizations: Solugen, Archer Daniels Midland

Solugen, a rapidly scaling climate technology company that is reimagining the chemistry of everyday life, and ADM (NYSE:ADM), a global leader in sustainable solutions, today announced a strategic partnership to scale a range of innovative, plant-based specialty chemicals and bio-based building block molecules in a new manufacturing facility in Marshall, Minnesota.

Read more at Business Wire

HP partners with Elnik, GKN and Sandvik on Metal Jet

📅 Date: November 3, 2023

✍️ Author: Davide Sher

🔖 Topics: Partnership, Additive Manufacturing

🏢 Organizations: HP, Elnik, GKN Additive, Sandvik

HP is focusing on further advancing and developing all aspects of its Metal Jet technology and, ahead of the Formnext show in Frankfurt, where the AM industry as a whole comes together to set the stage for the coming year, the company is presenting deals that are expected to improve various key aspects of the end-to-end metal binder jetting process. These include three key partnerships. The first is with Sandvik, one of the first companies to embrace metal binder jetting through partnerships with both ExOne (Desktop Metal) and GE Additive, on material development. Another one is with GKN Additive, a leading metal AM service that has been working with HP on Metal Jet from the get-go, on tooling and also material innovation (as GKN is also a provider of metal powders). And the third one is with Elnik, a leading manufacturer of furnaces for part sintering, to fine-tune this key aspect of metal binder jetting post-processing.

Read more at Voxel Matters