Endless Energy for Physical AI

This week: Hanover geothermal and Messe meetup, power-limited industry, operating at scale advantages, synthetic data for engineering, mapping thousands of automation projects, auto innovation.

Shop Talk

Capturing this week's zeitgeist

The city of Hanover isn't just home to one the World's largest trade fairs, it is also leading Germany's heating transition with a pioneering geothermal project that broke ground this October. In partnership with energy provider Enercity, Canadian cleantech company Eavor is implementing its innovative closed-loop Eavor-Loop™ technology to harness heat from 3,000 meters below the earth's surface. Set to deliver 30 megawatts of renewable thermal energy by spring 2027, this first-of-its-kind installation in a major German city will provide carbon-free heating for up to 20,000 homes, covering approximately 15% of Hanover's district heating needs. The project marks a significant milestone in the city's journey toward climate neutrality by 2035 and demonstrates how advanced geothermal solutions can effectively replace fossil fuels in urban energy systems.

Additionally, taking inspiration from the video game streaming world, where "raids" involve directing audiences to simultaneously visit another streamer's channel, Exponential Industry is bringing this collaborative energy to the manufacturing community. We're organizing an in-person "raid" at Hannover Messe, where our community of industrial tech enthusiasts will converge on select exhibitors to maximize networking impact and spotlight innovative solutions. Just as digital raids amplify visibility and build connections between gaming communities, our coordinated visit aims to create buzz around promising manufacturing technologies and foster valuable relationships. Stay tuned for next week's digest for the exact time and meeting location at Hannover Messe—this is your chance to be part of a unique approach to navigating one of the world's premier industrial technology showcases.

Assembly Line

This week's most influential Industry 4.0 media.

♨️ How the oil and gas industry can unlock endless Geothermal energy

Application of machine learning in early warning system of geotechnical disaster /AI Review/

⚙️ Why operating at scale lets metal fabricators ship faster

✍️ Author: Caleb Chamberlain

At OSH Cut, we’ve already benefitted from these scale economies. Our default lead time for laser cutting jobs up to three hours long is now just two business days at no extra cost. We also can turn orders around same day at a higher price, but we just dropped that price by about 70% for most orders. And we are doing this while simultaneously shipping more than ever before, with better than 98% on-time delivery.

There are naturally some important caveats. For starters, operations must support high-mix orders at scale. If production systems aren’t up to the task, then scale will beget confusion, quality issues, and late shipments, instead of statistical efficiency. Our solution to this problem is a combination of custom software and great people. We automate quoting, scheduling, purchasing, receivables, and machine programming. Operations are further simplified with in-house production tools that help our operators know what to do, how, and when.

Read more at The Fabricator

Novelis Unveils Industry's First Aluminium Coil Made from 100% Recycled End-of-Life Automotive Scrap /PR Newswire/

Decline of U.S. Primary Aluminum Production and the Growth of Secondary Aluminum /Light Metal Age/

Why Scrap Metal Recycling Companies Are Getting Partnership Offers from Mining Operators /Thermo Fisher/

💿 TCAD-Based AI Models For Modern Fab Workflows

✍️ Author: Saurabh Suryavanshi

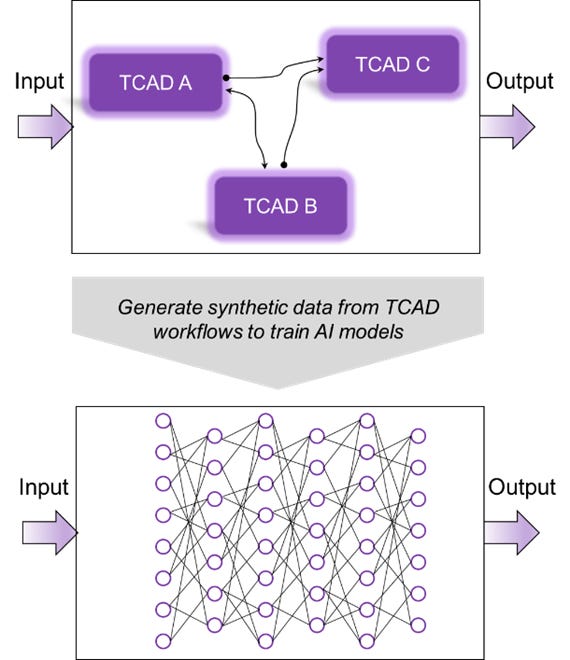

The complexity of modern chip fabrication makes experimentation in the fab very resource intensive. It takes too long and costs too much money for each turn of silicon to perform “what-if” experiments. The reliance on the empirical methods and wafers cannot be eliminated but it can be decreased if simulation tools are surgically deployed to help augment experiments. In between each learning cycle, engineers rely on technology computer-aided design (TCAD) tools to analyze the process and devices to predict results. The physics-based simulations provide high accuracy to experimental data, and TCAD engineers leverage them for “virtual fab runs” to supplement the wafer-based learnings.

TCAD tools offer an effective alternative to create synthetic data that can be used to train AI models. The simulation data is significantly cheaper than experimental data. This lower cost allows the TCAD tools to cover the full parameter space needed to create high fidelity AI models that can be targeted at the TD engineer’s workflows in the fab.

Read more at Semiconductor Engineering

Nvidia CEO says power-saving optical chip tech will need to wait for wider use /Reuters/

📊 Mapping 4,000 global industrial automation projects: Where Siemens, Emerson, Rockwell Automation, ABB, and Schneider Electric place emphasis

✍️ Author: Zeynep Kaman

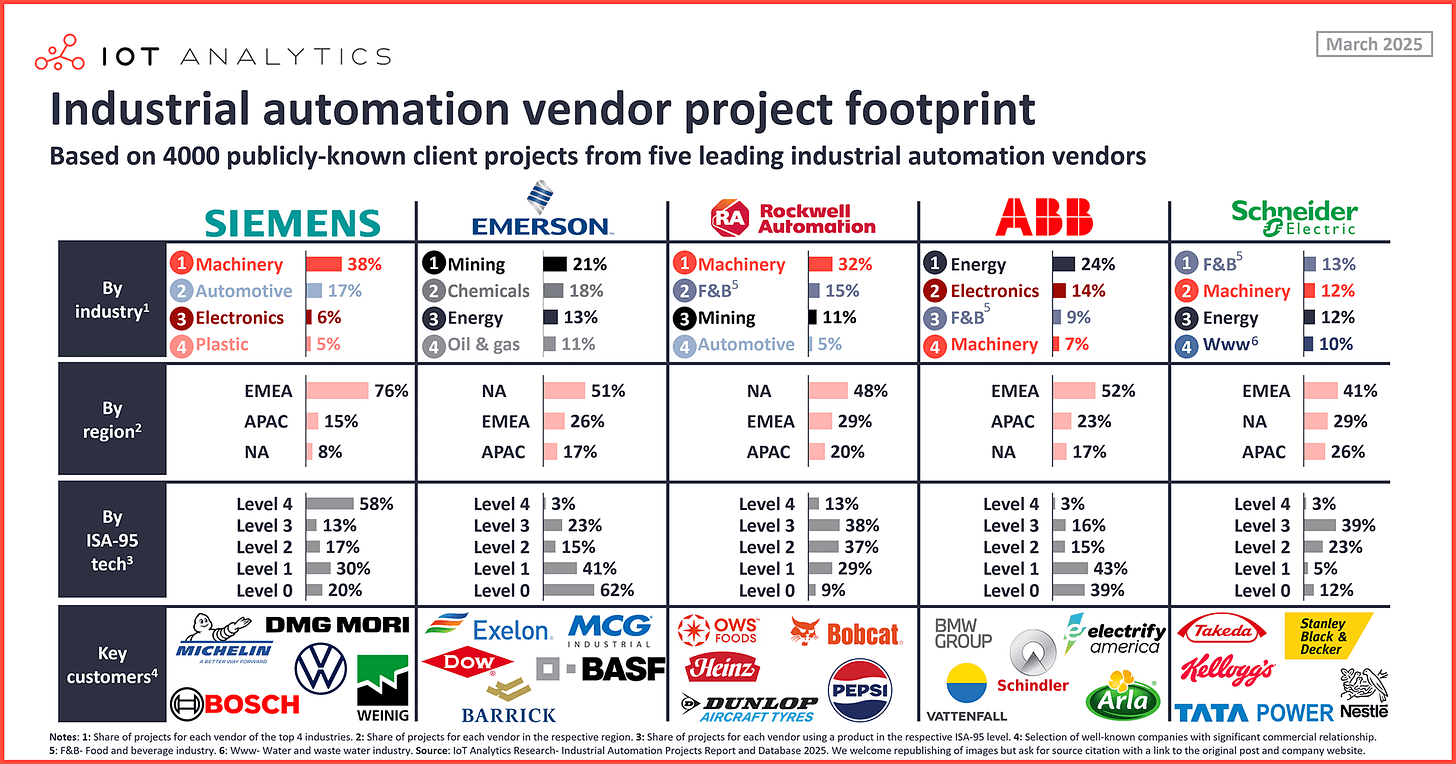

Analysis of over 4,000 project case studies gives insights into vendors’ areas of emphasis. IoT Analytics traditionally focuses on the intersection of industry and technology, right where industrial automation resides. As part of the ongoing research into industrial automation, the team has compiled a database of over 4,000 publicly shared customer projects from the websites of 5 leading industrial automation vendors: Siemens, Emerson, Rockwell Automation, ABB, and Schneider Electric.

Of the 4,000+ identified industrial automation projects, Siemens has the most with 45%, followed by Emerson at 28%. Approximately 44% of the projects involve discrete manufacturing automation, followed by 20% for hybrid manufacturing and 11% for process manufacturing. Among all the projects, ISA-95 Level 0 products appear the most at 38%, while Level 2 products appear the least at 19%.

Read more at IoT Analytics

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🧠📊 NVIDIA Omniverse Physical AI Operating System Expands to More Industries and Partners

NVIDIA unveiled at GTC that leading industrial software and service providers Ansys, Databricks, Dematic, Omron, SAP, Schneider Electric with ETAP, Siemens and more are integrating the NVIDIA Omniverse™ platform into their solutions to accelerate industrial digitalization with physical AI.

New NVIDIA Omniverse Blueprints connected to NVIDIA Cosmos™ world foundation models are now available to enable robot-ready facilities and large-scale synthetic data generation for physical AI development.

Read more at GlobeNewswire

Building Scalable Synthetic Data Generation Pipelines for Perception AI with Databricks and NVIDIA Omniverse /Databricks/

Collection of commercial-grade datasets for physical AI developers /Hugging Face/

Sight Machine Integrates NVIDIA Omniverse to Bring Unlimited AI Computing Power to the Shop Floor for 3D Visualization and Advanced Manufacturing Insights /PR Newswire/

“Every single data centre in the future will be power-limited. We are now a power-limited industry” - Jensen Huang at NVIDIA GTC

AI power: Expanding data center capacity to meet growing demand /McKinsey/

🛞 Bridgestone and Michelin test advances in puncture-free tyres

Bridgestone is pioneering puncture-proof tires that could accelerate the adoption of autonomous vehicles. The Japanese manufacturer has developed an air-free design capable of supporting a 1-tonne vehicle at 60km/h, dramatically outperforming solid tires from just a decade ago. Advanced computational modeling and new materials have enabled significant performance improvements at higher speeds and loads, positioning these tires as viable alternatives to traditional pneumatic options just as driverless technology demands maximum reliability and uptime. Currently being tested on shuttle buses and tourist vehicles, these innovations support Japan's initiative to deploy autonomous transportation in rural areas facing driver and mechanic shortages. This breakthrough technology may provide Bridgestone with a strategic advantage against increasing competition from Chinese and Indian manufacturers.

Read more at Financial Times

🚙 Japan's new gigacasting factory seeks to cut costs for EV builders

Japanese automaker supplier Ryobi has completed a factory to produce electric-vehicle body parts via gigacasting, a cost-saving technique pioneered by Tesla. The 3,400-square-meter facility sits on the grounds of the company's Kikugawa plant in Shizuoka prefecture. Investment totaled 5 billion yen ($33.5 million). The new factory "brings together the finest of our die-casting technology," Ryobi President Akira Urakami said Monday, the day of a media tour.

Read more at Nikkei Asia

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇺🇸🌬️ SkySpecs Raises $20m to Fuel Global Growth and Innovation

SkySpecs, a global leader in renewable energy asset health management, autonomous drone inspections, and tech-enabled software solutions, has raised $20 million in strategic growth capital led by Goldman Sachs Alternatives, with additional participation from key renewable energy investors including Statkraft and Equinor Ventures. This investment underscores the confidence in SkySpecs' market leadership and its ability to drive innovation and scalability worldwide.

With 125 global customers and over 270,000 turbines inspected to date, SkySpecs has the largest blade data repository in the industry. This dataset, combined with the company’s deep domain expertise, a fleet of cutting-edge autonomous drones, enables customers to make data-backed decisions that enhance asset performance and profitability.

Read more at Businesswire

🇦🇹🌬️ AI-controlled drone swarms to inspect wind turbines in the future /University of Klagenfurt/

🇺🇸🔋 Coreshell Raises $24M To Commercialize the Lowest-Cost and Domestically-Sourced Lithium-Ion Battery Anode

Battery technology company Coreshell announced a $24M in strategic funding aimed at scaling production of its 60 Ah battery cells made with 100% domestically-sourced metallurgical silicon (MG-Si). The round was anchored by Coreshell's strategic partner Ferroglobe PLC (NASDAQ: GSM) - a global leader in the production of Silicon and Ferroalloys, and Zeon Ventures. Additional financial and returning investors include Lane Ventures, Entrada Ventures, Foothill Ventures, Helios Climate Ventures, Translink Investment, Trousdale Ventures, and Asymmetry Ventures.

This funding will go towards scaling Coreshell's production at its newly-built 4 MWh manufacturing facility in San Leandro, California, with plans for a separate 100 MWh facility currently in site selection and design. As a result of this production scale-up, the company is now positioned to meet growing demand and will begin delivering commercial samples of its 60 Ah battery cells to global automakers in 2025.

Read more at PR Newswire

🇩🇪🔋 PULSETRAIN secures €6.1 million to radically improve EV battery performance and lifespan /Businesswire/

🇮🇱🪙 LimitlessCNC Aims to Revolutionize Manufacturing with AI and bring Production Back to the West

LimitlessCNC, an AI-driven manufacturing startup, has emerged from stealth with a $4.1M seed round led by Grove Ventures and Meron Capital. The company is developing AI agents to automate CNC (computer numerical control) machining—a trillion-dollar industry struggling with labor shortages.

LimitlessCNC leverages physics-based AI to optimize machining processes and generate efficient production programs. This enables manufacturers to reduce CNC programming time by up to 80%, eliminating a bottleneck in production. The AI agents optimize workflows by learning from historical machining data and simulating the physics of metal cutting, ensuring precision, speed, and cost efficiency for every new production process.

Read more at PR Newswire

🇸🇪 Sandvik: CNC AI Agents /The Industrial AI Podcast/

🇺🇸💧 Noble Gas Systems Receives $4.2 Million in Series B Funding

Noble Gas Systems, a developer and manufacturer of innovative, conformable high-pressure hydrogen gas storage vessels, announced it has raised $4.2 million in this initial closing of Series B funding. Funds were provided by AP Ventures, which supported Noble Gas in its Series A Funding, with participation from new investors ALIAD (Air Liquide Venture Capital) and NOVA by Saint-Gobain, the venture arm of Saint-Gobain.

The funding will support development testing of the company's 700 bar (10,000 psi) design qualifications and completion of the application process to receive the U.S. Department of Transportation (DOT) Special Permit for Noble Gas storage vessels to be used in bulk storage and over-the-road transportation of hydrogen and other gases. Additionally, the funding will help accelerate the development of the pilot manufacturing plant and expand the research and development teams.

Read more at PRWeb