Electrifying the World: A Look at the Top Battery Plants Across the Globe

Exponential Industry maps global battery plants from Ratel Consulting's "Global Battery Factory Database". Explore the top ten gigafactories for electric vehicles and renewable energy storage.

It takes time to power up. As the world shifts towards an electric future, electric vehicles (EVs) are becoming increasingly popular. However, EVs are only as good as the batteries that power them, making the production of high-quality EV batteries essential. Over the past decade, there has been a significant increase in battery manufacturing plants worldwide, with many of these facilities investing heavily in research and development to create batteries with higher energy density, longer lifespans, and faster charging times.

In this series of articles, we will take a closer look at some of the most significant battery plants around the world, examining the manufacturing processes, the technologies employed, and the production capacity (GWh) of each facility. From Asia to Europe and North America, we will explore the key players in the battery industry and how they are leading the charge toward an electric future.

Battery Manufacturing Capacity Set to Surge

With the growing demand for electric vehicles, battery manufacturers are expanding their production capacity at an unprecedented pace. According to the Federal Reserve Bank of Dallas, the global manufacturing capacity of EV batteries is expected to increase exponentially in the coming years. China alone is projected to reach 4,500 GWh of battery production capacity by 2031, which is four times the current capacity. Meanwhile, the United States is also aiming to ramp up its battery manufacturing capacity to reduce its dependence on imports and establish a local supply chain following the passage of the Inflation Reduction Act and CHIPS and Science Act. This surge in battery production capacity is a positive sign for the EV industry as it will help make electric vehicles more affordable and accessible to consumers.

To keep up with this demand, manufacturers are building gigafactories, which are massive battery factories that exceed an annual capacity of 1 gigawatt-hour (GWh) of batteries per year. These facilities are critical for the future of sustainable energy, as they allow for economies of scale and reduce the cost of batteries by streamlining the manufacturing process. As the market for electric vehicles and renewable energy storage continues to grow, the need for gigafactories will only increase. These factories are essential for ensuring that the world's transition to sustainable energy is feasible and cost-effective.

Leading Companies in Battery Manufacturing

Our initial post in this series focuses on the six most mature battery manufacturing companies and their top plants representing an estimated 442 GWh in annual capacity. These facilities account for nearly half the total expected capacity worldwide (~1000 GWh) for 2023. Many of these plants started in the early 2010s and have scaled with demand ever since. The first big U.S. EV-Battery plant offers lessons in building factories, training workers, and developing supply chains.

Note: Exponential Industry biases to primary sources by aggregating thousands of company blogs, press releases, podcasts, deep-dive articles, and videos directly from where they are originally published. Capacity estimates were augmented by EI in partnership with Ratel Consulting’s “Global Battery Factory Database.”

Contemporary Amperex Technology Co. Limited (CATL)

🏭📍Fuding, Ningde, Fujian, China (65 GWh 2023 Capacity / 120 Planned Max Capacity); Liyang, Jiangsu, China (40/40); Yibin, Sichuan, China (24/75)

CATL was established in 2011 with two major lines of business:

Provide EV battery systems and services for green transportation

Provide solutions and services for clean energy storage

CATL has been ranked number 1 globally in EV battery consumption volume for five consecutive years. CATL’s Ningde and Sichuan factories are WEF Lighthouse factories. With headquarters in Ningde, China, CATL has created a global footprint across Asia, Europe, and North America.

LG Energy Solutions (LGES)

🏭📍Wrocław, Poland (70/115); Nanjing, Jiangsu, China (60/60)

LG Energy Solutions split off from LG Chem in Septemeber 2020 and inherited a global footprint. Their flagship battery factory resides in Wrocław, Poland and is currently reported to be highest capacity battery factory in the world.

LG Energy Solution Wrocław is Europe's largest and the world's leading producer of lithium-ion batteries for the automotive industry. In Biskupice Podgórne (Kobierzyce commune) we manufacture all battery elements up to the product ready for installation in a car.

In 2019, they founded a joint venture with General Motors called Ultium Cells.

Ultium Cells is focused on the future of the transportation industry and its impact on the world, both culturally and environmentally. Battery cells are an important step away from fossil fuels, but they also have the potential to revolutionize passenger vehicles as fundamentally as the internal combustion engine did all those years ago. We embrace this potential by manufacturing our battery cells in cutting-edge facilities where quality and safety are the top priorities.

Panasonic & Tesla

🏭📍Sparks, Nevada, USA (38/140); Lathrop, California, USA (20/40)

Tesla and Panasonic started their joint operations together in 2014.

We made a commitment to invest $3.5 billion in Nevada with our first Gigafactory. Our goal was to build a facility capable of producing 35 GWh of battery cells annually—enough to manufacture about 500,000 vehicles per year.

Since then they have continued to invest billions into Gigafactory Nevada.

They are planning two new factories: a 100 GWh 4680 cell factory (with capacity to produce enough batteries for 1.5 million light duty vehicles annually), as well as our first high-volume Semi factory. Semi is our fully electric combination truck, with 500 miles of range and energy consumption of less than 2 KWh per mile.

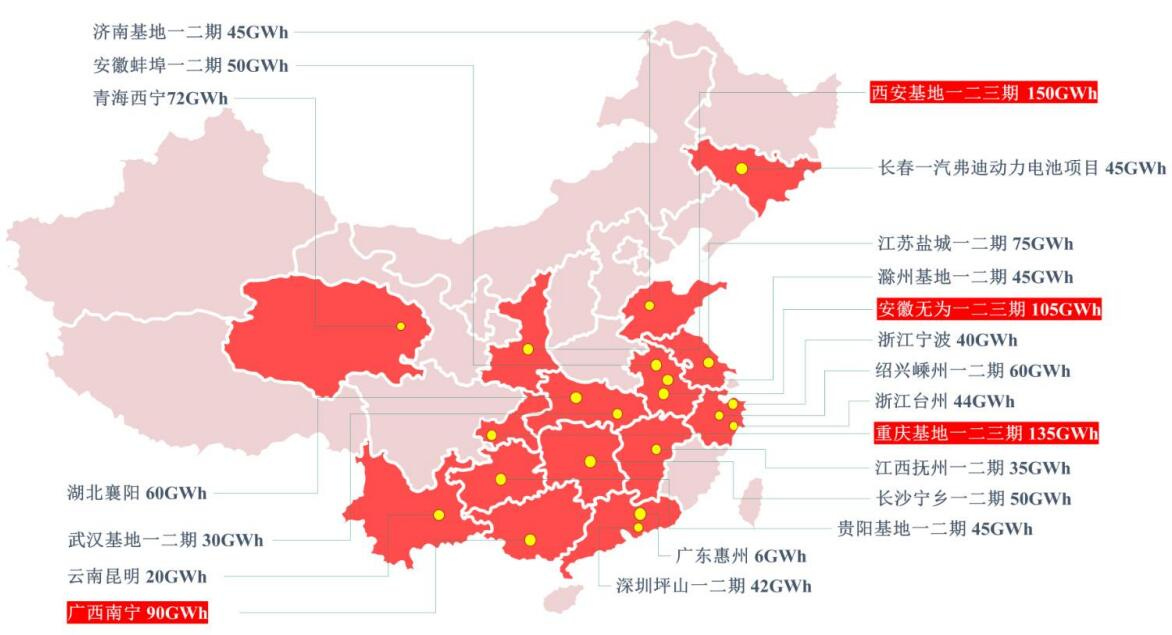

BYD Company

🏭📍Xining, Qinghai, China (26/36); Bishan, Chongqing, China (20/35); Bengbu, Anhui, China (20/20)

BYD is a seculsive company with hard to verify manufacturing capacity given they operate primarily in China.

With more than 25 years’ continuous innovation, the company offers a wide variety of battery products, such as consumer 3C batteries, power batteries, solar cells and energy storage batteries, and has a complete battery ecosystem. In addition to applications in new energy vehicles and rail transportation, BYD’s battery products are widely used in solar power stations, energy storage power stations and many other new energy solutions.

BYD’s Blade Battery is known for it’s stability as compared to other battery types and chemistries.

The singular cells are arranged together in an array and then inserted into a battery pack. Due to its optimized battery pack structure, the space utilization of the battery pack is increased by over 50% compared to conventional lithium iron phosphate block batteries.

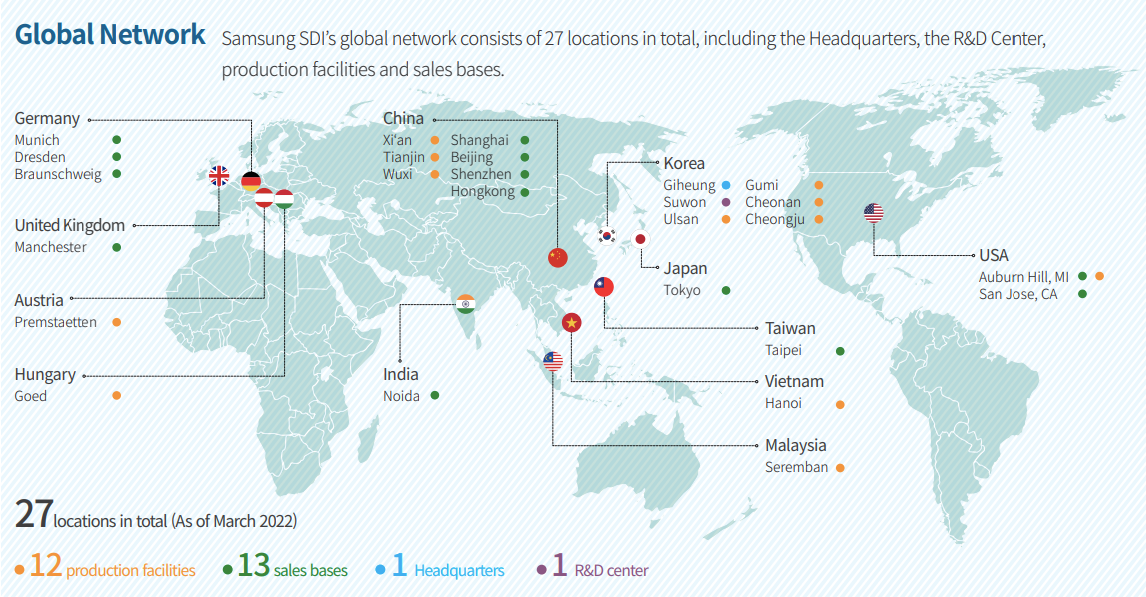

Samsung SDI (Samsung)

🏭📍Göd, Hungary (37/40)

Since its foundation back in 1970, Samsung SDI produces and sells rechargeable batteries used for electric vehicle, IT device, and Energy Storage System (ESS) applications as well as materials for semiconductors and displays. We are committed to building new growth drivers through transformation and innovation to emerge as a ‘Creative Energy and Materials Solution Leader’.

Samsung SDI operates a global network with 12 production facilities. The Göd, Hungary plant remains its largest production facility.

Northvolt Ett

🏭📍Skellefteå, Sweden (22/60)

Lastly, Northvolt leads the way in Europe with its battery technology.

Marking a new chapter in European industrial history, the cell is the first to have been fully designed, developed and assembled at a gigafactory by a homegrown European battery company.

Next Week: The Technology Behind the Power

The global race for battery production continues to intensify as manufacturers strive to meet the growing demand for sustainable transportation and energy storage. With China leading the charge in terms of production capacity, several other countries and companies are not far behind. From Tesla's gigafactories to CATL's state-of-the-art facilities, battery manufacturers across the globe are investing heavily in R&D and production to capture a larger share of the market. In the next post, we'll dive deeper into the manufacturing technology behind these top battery plants, exploring the latest innovations and breakthroughs that are driving the electric revolution forward. Stay tuned!