Counting the Pieces to Assemble 🧩

This week: Will Toyota EVentually find its way?, industrial grade agave, bamboo, flax, and kenaf materials, electrokinetic mining, soft sensing of industrial processes, and robot playgrounds.

Shop Talk

Capturing this week's zeitgeist

Really excited to be posting our FIRST Robotics hardware roles for OpenAI, including two very senior tech lead engineering (IC) roles and a TPM Manager.

In the race to build the next generation of robots, particularly humanoids, AI giants are making an audacious bet: that their mastery of artificial intelligence will unlock the secrets of physical automation. OpenAI, Tesla, and NVIDIA aren't just writing code - they're creating virtual worlds where digital robots learn and fail millions of times before their physical counterparts take a single step. While these tech titans are staking their ownership claim of the 'robot mind,' a more pressing question emerges: who will forge their bodies?

Assembly Line

This week's most influential Industry 4.0 media.

🚗 How Long Can Toyota Put Off Figuring Out EVs?

✍️ Authors: Reed Stevenson, Chester Dawson

Toyota’s first global EV, the bZ4X, illustrates how traditional automotive manufacturing wisdom can become a barrier to innovation. While Toyota’s Production System excels at incremental improvements, exemplified by their steel cross-car beam refined over decades for ICE vehicles, EV leaders Tesla and BYD have reimagined components from scratch. Their plastic beam equivalent weighs just 14 pounds, costs less, and is simpler to install - a solution that emerged from thinking beyond traditional constraints.

This divide extends to broader manufacturing strategies. Tesla and BYD operate more modular facilities with increased in-house production, designing proprietary components for EVs that use roughly one-third the parts of conventional vehicles. Meanwhile, Toyota’s EV production requires compromises, like moving body frames off the main assembly line for battery installation - a workflow that manufacturing executive Susan Elkington acknowledges isn’t optimal but provides needed flexibility during the transition.

The situation highlights a crucial insight from former GM executive Terry Woychowski: “You cannot kaizen yourself from an ICE vehicle to a BEV.” For traditional automakers, the path to competitive EV manufacturing may require more revolutionary than evolutionary thinking.

Read more at Bloomberg

🚙 Automobiles piece by piece:

📐 CAD Software Aids Wire Harness Design [Assembly]

🎍 Automakers Opt for Sustainable Materials: agave, bamboo, flax, kenaf and seaweed [Assembly]

🖨️3️⃣ Using 3D printing technology to replace the manufacturing process of a headlight lens [Optica]

🤝 Vianode signs USD multi-billion long-term supply agreement for EV battery-grade anode graphite with GM [Vianode] and BMW Group scores circular economy win with SK tes high-voltage batteries [BMW]

🦾 Dürr equips first BYD plant in Europe with sustainable painting technology [Dürr]; 🗜️while 5,000t and 9,000t die casting equipment is installed at BYD’s new industrial park in Shenzhen

📸 Manufacturing safe electric vehicle parts at BorgWarner using Cognex artificial intelligence [YouTube] and Mech-mind’s AI+3D Vision-Guided High-Precision Rolling of Auto Door Seals [YouTube]

♻️ ENGEL’s Two-stage process for Energy-efficient Plastics Recycling

⛏️ Industrial-scale sustainable rare earth mining enabled by electrokinetics

✍️ Authors: Gaofeng Wang, Jianxi Zhu, Xiaoliang Liang

🏢 Organizations: Chinese Academy of Sciences

Owing to their irreplaceable role in several essential technologies, rare earth elements (REEs) are critical raw materials for the global economy. However, the supply of REEs raises serious sustainability concerns due to the large environmental footprint of conventional mining processes. We previously proposed an electrokinetic mining (EKM) technique that could enable green and selective extraction of REEs from ores. Here we further develop this technique to industrial scale by addressing challenges related to electrode reliability and flow leakage and evaluate its mining efficiency, environmental footprint and economic performance. Moreover, a voltage gradient barrier strategy based on electroosmosis is developed to facilitate electrokinetic REEs mining. As a result, we successfully achieved a high REE recovery efficiency of 95% on a 5,000-ton REEs ore. A rigorous environmental risk assessment revealed a 95% reduction of ammonia emissions, indicating a notably reduced environmental footprint. A comparative technoeconomic analysis between the conventional and the EKM techniques demonstrates the economic viability of the EKM technique. This work validates a new sustainable path for REEs mining, paving the way to a greener resources supply.

Read more at Nature Sustainability

⚒️ Drilling through the crust:

🗣️ Watt It Takes: KoBold Metals Co-Founder and CEO Kurt House [Spotify]

💰 XtremeX Mining Technology Announces Plans for First Deployment of Its Revolutionary Mineral Drilling Rig with Ivanhoe Electric Following an $11M Series-A Financing Led by GoGreen Partners [Business Wire]

🙅♂️ Rio Tinto and Glencore merger talks, what’s next? [Financial Times]

🇨🇳 Shein: Inside the Chinese factories fueling the fashion giant’s success

🧱 Inside the Great Wall:

📰 Analysis: How China Can Kick Its Overcapacity Habit [Caixin]

🚙 Audi Starts Production of Electric Models at New Factory in China [YouTube]

⭐ Visiting Komaspec’s factory in Guangzhou [YouTube]

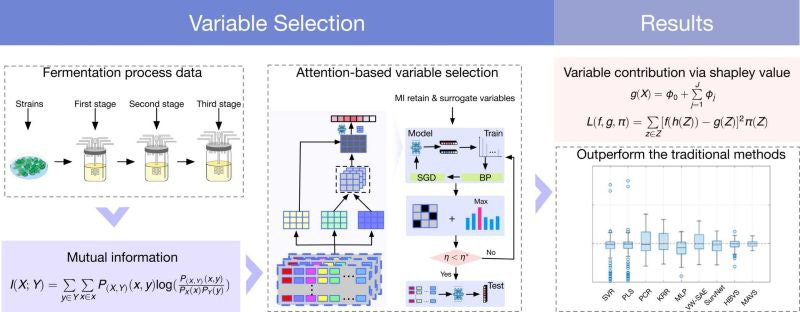

🎛️🎚️ Mutual information and attention-based variable selection for soft sensing of industrial processes

✍️ Authors: Zhenhua Yu, Guan Wang, Xuefeng Yan

This study introduces a novel method called mutual information (MI) and attention-based variable selection (MAVS) to address the challenges of irrelevant and redundant variables in industrial process soft sensing while providing interpretability in variable contribution analysis. First, irrelevant variables are eliminated based on low MI values with the quality variable. Second, attention scores are used to remove redundant variables, and the false discovery rate is used to determine the number of beneficial variables. Finally, this work provides an interpretable and accurate contribution of the selected variables by using kernelSHAP, a kernel-based Shapley analysis. Unlike traditional approaches, MAVS integrates MI with attention mechanisms to optimize variable selection dynamically and adaptively. MAVS obtains stronger robustness and higher accuracy than the existing state-of-the-art models through optimal variable selection. The former also obtains better superior generalization than the latter through adaptive adjustment of attention weights. The superiority of MAVS is demonstrated using two real-world datasets and one simulated dataset.

Read more at Journal of Process Control

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

📟 ABB Robotics introduces AppStudio no-code tool for robot interface programming

ABB launched AppStudio, an intuitive no-code software tool designed to empower users of all experience levels to quickly and easily create customized robotic user interfaces. With intuitive functionality and features including a collaborative cloud-based library enabling users to share application templates, AppStudio will reduce setup times by up to 80 percent. AppStudio is available as a free download.

Read more at ABB News

🦾 Do more with robots:

MuJoCo Playground, a fully open-source framework for robot learning built with MJX, with the express goal of streamlining simulation, training, and sim-to-real transfer onto robots, has launched.

☢️ ‘A viable business’: Rolls-Royce banking on success of small modular reactors

A new wave of nuclear technology is emerging as an alternative to massive projects like Hinkley Point C. Small modular reactors (SMRs), which can be factory-built and assembled on-site, are being pitched as a faster, more cost-effective path to nuclear power generation. Rolls-Royce, leveraging its submarine reactor expertise, is competing with three North American firms for UK government contracts.

The key innovation is modularity: these pressurized water reactors are manufactured in truck-sized components for on-site assembly, requiring just two hectares for Rolls-Royce’s design. This factory-based approach contrasts sharply with traditional nuclear projects’ complex on-site construction, potentially offering significant efficiency gains.

Read more at The Guardian

⏯️ Reviving nuclear power plants:

The lights are turning back on at Three Mile Island in Pennsylvania [YouTube]

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇩🇪 🦾🤖🦿 NEURA Robotics Secures €120 Million in Series B Funding to Propel Cognitive and Humanoid Robotics Vision

NEURA Robotics, cognitive robotics pioneer and the only humanoid robotics company in Germany, announced it has raised €120 million in a Series B funding round. This substantial investment underscores NEURA Robotics’ key role in cognitive robotics, showing how it is uniquely positioned to lead the European robotics industry and become a major force in the global robotics landscape, alongside strong players in the US and China. The round was led by Lingotto Investment Management, with participation from BlueCrest Capital Management, Volvo Cars Tech Fund, InterAlpen Partners, Vsquared Ventures, HV Capital, Delta Electronics, C4 Ventures, L-Bank, founder David Reger, and others.

Founded in 2019, NEURA Robotics has quickly become a global leader in cognitive and humanoid robotics, creating robots designed to work seamlessly with humans in industries such as manufacturing, logistics, and healthcare. With its unique sensor technology and AI integration, NEURA Robotics has the world’s first cognitive cobot in the market and is now leading the way in the development of market-ready humanoid robots. In the last year alone the NEURA team doubled its number of employees to over 300 people and achieved a remarkable 10x revenue growth. Under the leadership of founder and CEO David Reger, NEURA Robotics has already secured an impressive €1 billion order book.

Read more at Business Wire

🇫🇷 🚛 Shippeo Raises $30m Strategic Round Led by Woven Capital to Accelerate US and APAC Expansion

Shippeo, a global leader in real-time multimodal transportation visibility, announced a $30 million strategic funding round led by Woven Capital, Toyota’s growth fund, with participation from existing investors: Battery Ventures, Partech, NGP Capital, Bpifrance Digital Venture, LFX Venture Partners, Shift4Good, and Yamaha Motor Ventures. This new funding will support Shippeo’s accelerated expansion across North America and APAC while driving enhancements to its industry-leading Real-Time Transportation Visibility Platform. With this round, Shippeo’s total funding exceeds $140 million.

Shippeo offers real-time shipment tracking across all transport modes, helping companies create sustainable, resilient supply chains. Its platform enables users to reduce logistics-related carbon emissions by making informed trade-offs between modes and carriers based on carbon footprint data. In response to years of global supply chain disruptions, Shippeo has prioritized transportation risk management as a core capability, with a strong emphasis on data quality and customer-focused innovation that distinguishes its solutions.

Read more at Business Wire

🇺🇸💧 Amogy Raises $56 Million to Bolster Commercialization of Pioneering Ammonia-to-Power Solutions

Amogy, a provider of mature, scalable, and efficient ammonia-to-power solutions, announced that it raised $56 million in venture financing, bringing total raised since inception to more than $270 million. The round was co-led by existing investor Aramco Ventures and new investor SV Investment. Additional new investors participating in the round include Samsung Heavy Industries, BHP Ventures, Hanwha Investment & Securities, AFW Partners, Quantum Ventures Korea, Kibo Invest, and Seoul IP, along with existing investors Temasek, MOL Switch, Yanmar Ventures, AP Ventures, and Marunouchi Innovation Partners.

This financing follows the latest successful demonstration of Amogy’s ammonia-to-electrical power system where it sailed the world’s first carbon-free, ammonia-powered maritime vessel in September 2024. In earlier demonstrations, the company successfully used its technology to power an aerial drone, commercial farm tractor, and semi-truck. Amogy’s patented ammonia-powered system splits, or “cracks,” ammonia into its base elements of hydrogen and nitrogen. The hydrogen is then funneled into a hydrogen-to-power system, either an integrated fuel cell or hydrogen engine, generating high-performance power with zero carbon emissions.

Read more at Business Wire

🇺🇸🦾 Symbotic to Acquire Walmart’s Advanced Systems and Robotics Business

Symbotic Inc. (Nasdaq: SYM), a leader in A.I.-enabled robotics technology for the supply chain, announced it has agreed to acquire the Advanced Systems and Robotics business from Walmart (NYSE: WMT). This transaction expands the long-standing relationship between Walmart and Symbotic with the aim of developing an integrated automated supply chain.

Read more at Business Wire