Chemically Stable Operating Footprint

This week: Chemical industry action plans, dark factories, competing with China, AI predicts manufacturing outcomes, robots learning from demonstration, autonomous dual-mobile road-to-rail platform.

Shop Talk

Capturing this week's zeitgeist

Look at our site in Cologne. It is one of the most advanced integrated petrochemical facilities in Europe. Compared to the US, our gas bill is €100 million higher. Electricity is €40 million more. And our carbon costs are heading towards €100 million annually. That’s €240 million in additional cost every year, just to operate in Europe.

The European Commission’s Chemical Industry Action Plan fails to tackle the two most immediate threats to the survival of Europe’s chemical industry: the high cost of natural gas and the escalating cost of allowances for carbon emissions, according to Tom Crotty, director of corporate affairs for the UK-based chemical maker Ineos. The European Chemical Industry Council (Cefic) estimates that 5% of Europe’s chemical production capacity was shut down in 2023 due to uncompetitiveness. More plant closures followed in 2024, and more have been announced this year.

This is in stark contrast to the United States, where natural gas prices remain competitive, and the president is attempting to ease the burden on chemical manufacturers, in part because no technology exists to comply with emissions standards.

On May 16, 2024, the Environmental Protection Agency published a final rule titled New Source Performance Standards for the Synthetic Organic Chemical Manufacturing Industry and National Emission Standards for Hazardous Air Pollutants for the Synthetic Organic Chemical Manufacturing Industry and Group I & II Polymers and Resins Industry, 89 FR 42932 (HON Rule). The HON Rule imposes new emissions-control requirements on certain chemical manufacturing facilities, some of which were promulgated pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412.

In support of this Exemption, I hereby make the following determinations:

a. The technology to implement the HON Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the HON Rule by the compliance dates in the HON Rule.

Who is building the technology to implement the HON Rule? If you have tips, please reply to this email and let’s discuss.

Assembly Line

This week's most influential Industry 4.0 media.

🏭🌑 China’s Dark Factories: So Automated, They Don't Need Lights

Ford’s CEO says China’s EV industry poses an existential threat to global automakers. The country’s dark factories, which operate with robots running 24/7 and limited human interaction, aim to widen the gap further between Chinese car manufacturers and their competitors. As China grapples with overproduction and Trump’s trade war with Beijing continues, one big question remains: Who will buy all these vehicles?

Panasonic Opens Kansas EV Battery Plant /YouTube/

How BYD caught up with Tesla in the global EV race /FT/

Opinion: The End of ‘Growth at All Costs’ /Caixin/

How Renault is speeding up car development to match Chinese rivals /FT/

GM’s Final EV Battery Strategy Copies China’s Playbook: Super Cheap Cells /Wired/

Legislators Embrace Technology Recycling to Compete With China /WSJ/

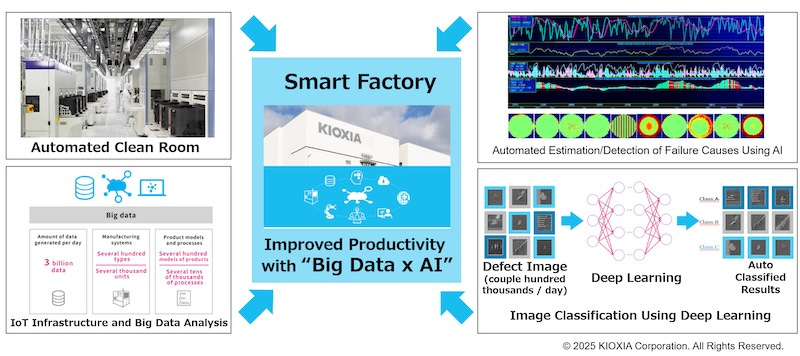

💿 The Yokkaichi Plant of KIOXIA is at the forefront of Flash Memory Innovation

In addition to the highly automated cleanrooms, the Yokkaichi Plant collects 3 billion data points from all locations every day and analyzes them in real time using AI. The use of AI enhances the various types of analyses, including automatic estimation of the cause of defects by machine learning and image classification by deep learning, as well as to visualize issues and areas for improvement.

KIOXIA also turned to digital twins, and they are being used to promote collaboration between the Yokkaichi Plant and the Kitakami Plant (Kitakami City, Iwate Prefecture), which has been mass-producing flash memory since 2020. Recreating the Plants in a virtual environment in real time allows for the optimization of the manufacturing process by taking full advantage of the data obtained from manufacturing equipment and systems. Applying this procedure to the Yokkaichi and Kitakami Plants has allowed the Kitakami Plant to become operational in record time and to achieve a higher yield more efficiently than usual.

Read more at EE Times

How Gas Purity Protects Yield, Quality, and Uptime in Semiconductor Fabs /Thermo Fisher/

B&R Relies on KNAPP Technology for New Smart Factory /KNAPP/

🖨️ What’s Wrong With 3D Printing? A Material Scientist Explains.

About 80% of companies I see don’t fully control their process. They’re essentially experimenting—cooking without a recipe. But the top 20% are getting much better, and maybe 1% have reached true precision, where they can produce aerospace-grade parts repeatably. A large majority of the companies do not need precision and for them, investing in material science is not viable. But the 20% need somewhat good precision and 1-2% high precision. Many of these have truly invested in R&D to understand material-laser interaction and dynamic processes. These companies are leapfrogging their competition.

AI can’t invent new physics, but it can help predict outcomes. If you train it on high-quality data—like phase diagrams and prior results—it can recommend process parameters: laser power, scanning speed, cooling rates. That helps you approach the theoretical performance limits of a material instead of settling for trial and error.

Read more at ENGtechnica

Dual-Wavelength Simultaneous Patterning of Degradable Thermoset Supports for One-Pot Embedded 3D Printing /ACS Central Science/

Why Sinter Chemistry is Important and How to Get it Right /Thermo Fisher/

🦾 New tool gives anyone the ability to train a robot

✍️ Author: Jennifer Chu

The team’s new work builds on an emerging strategy in robot learning called “learning from demonstration,” or LfD, in which robots are designed to be trained in more natural, intuitive ways. In looking through the LfD literature, Hagenow and Shah found LfD training methods developed so far fall generally into the three main categories of teleoperation, kinesthetic training, and natural teaching. Shah and Hagenow wondered whether they could design a tool that combines all three methods to enable a robot to learn more tasks from more people.

With that goal in mind, the team engineered a new versatile demonstration interface (VDI). The interface is a handheld attachment that can fit onto the arm of a typical collaborative robotic arm. The attachment is equipped with a camera and markers that track the tool’s position and movements over time, along with force sensors to measure the amount of pressure applied during a given task.

Read more at MIT News

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

🏭☁️ Digital Factory Demo: A Faster Way to Show the Power of Litmus

The Digital Factory Demo is a ready-to-deploy virtual environment that simulates a smart factory—complete with PLCs, containerized apps, digital twin templates, historical data, and live dashboards. It gives new users, partners, and buyers a real-world look at Litmus Edge in action, without needing to connect to a single physical device.

Read more at Litmus

UNS Payload Examples provides sample schemas and examples for industrial MQTT payloads following Unified Namespace (UNS) principles /GitHub/

🏭🧠 Sight Machine’s Operator Agent Brings Agentic AI to the Plant Floor

Sight Machine introduced Operator Agent, built to turn every plant-floor operator into a data-driven decision maker. Operator Agent uses multiple AI agents to make it easier for operators to maximize throughput, troubleshoot machine problems, reduce downtime, and improve quality.

The AI Agents have both an API for interacting with other software systems and a copilot natural language chat interface for Q&A or report generation by operators and engineers on the plant floor. Questions coming from the API or copilot are first routed to an orchestration agent – an LLM that processes the user’s intent, routes the questions to the appropriate tools or other agents, and aggregates responses. The analysis is performed by a set of specialist agents tuned to handle specific types of data analysis and predictive analytics. Each of these analysis agents has a set of previously trained and validated machine learning models, which help to ensure accuracy of the results.

Read more at Sight Machine

🚛🦿🚃 Glīd Technologies Delivers: The World’s First Autonomous Dual-Mobile Road-to-Rail Platform

✍️ Author: Angela Scott-Briggs

History was made at the 2025 New Mobility Futures event follow Reindustrialize in Detroit, Michigan. Glīd Technologies, unveiled the world’s first unmanned, autonomous, dual-mode road-to-rail platform, which is a Mobility-as-a-Service (MaaS) platform. Glīd Tech is combining its sophisticated AI-powered orchestration software, called EZRA-1SIX, with its hybrid-electric crewless ground vehicle, called Rāden.

Rāden is an autonomous hybrid-electric vehicle approximately 94 inches wide, 264 inches long, and 54 inches high. It is designed for road and rail transportation, particularly high-payload operations with a capacity of between 4,000 and 10,000 pounds that take place off the grid. The uncrewed Rāden vehicle can travel up to 65 miles per hour on roads and up to 25 miles per hour on rail tracks, providing a total operational range of up to 600 miles. The most impressive feature is how the vehicle automatically transitions from the road to the rail tracks in transload zones without requiring human intervention. It eliminates common bottleneck problems in transload zones, where manual intervention typically leads to increased costs, injuries, and delays.

Read more at TechBullion

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇺🇸 Hadrian Raises $260M to Build AI-Powered Factories for America, Adds Full Product Manufacturing, Opens Arizona Site

Hadrian, the advanced manufacturing company building AI-powered factories for America, announced $260 million in new capital and major expansions of its footprint in California and Arizona. The raise includes $260 million in Series C financing led by existing investors Founders Fund and Lux Capital, and a factory expansion loan facility arranged by Morgan Stanley. This capital will accelerate Hadrian's ability to deliver not just precision parts but full mission-critical systems. The company now covers the entire advanced manufacturing stack, from raw material to finished products, and supports everything from components to assemblies to complete platforms. With its "Factories-as-a-Service" model, Hadrian can rapidly scale production across key Department of Defense (DOD) areas such as munitions, shipbuilding, and other high-priority programs.

Read more at PR Newswire

🇺🇸 Firestorm Labs Announces $47 million Series A Funding to Accelerate Growth and Innovation in Defense Technology /PR Newswire/

🇺🇸 Auriga Space raises $6M to shoot rockets off an electromagnetic launch track /TechCrunch/

🇺🇸 Bedrock Robotics Emerges from Stealth with $80M in Funding for Autonomous Construction Technology

Bedrock Robotics, the company developing advanced autonomous systems for the $13 trillion global construction industry, emerged from stealth with $80 million in Seed and Series A backing. Rather than design and sell costly new machinery, Bedrock upgrades customers' existing heavy equipment fleets with reversible, same-day hardware and software installs to enable fully autonomous operations.

Founded by three former Waymo leaders - including the former head of its trucking program - and a fourth co-founder who previously led teams at Segment, the Bedrock Robotics leadership team brings extensive experience across machine learning, system architecture, and operation of autonomy technologies in complex, safety-critical environments. Now, the company's executives are applying their expertise to construction to improve cost, schedule, safety, and predictability of labor-intensive projects. Laurent Hautefeuille, previous EVP at Uber Freight responsible for building the business from inception to $5B in revenue, has recently joined Bedrock as COO.

Read more at PR Newswire

🇦🇹 Fiber Elements raises €2.6M for the fully automated production of three-dimensional basalt fiber structures, offering a sustainable alternative to steel-reinforced concrete. /Fiber Elements/

🇺🇸 H2Ok Innovations Raises $12M Series A for AI-Powered Sensors That Disrupt and Transform CPG Manufacturing

H2Ok Innovations, the only provider of patented inline sensors powered by science and AI to run faster factories, announced a $12.42M Series A round of funding led by Greycroft. Additional participation in H2Ok’s Series A comes from 2048 Ventures and Construct Capital. This funding comes as H2Ok Innovations’ technology is already being used by major global CPG and hyperscale data center companies to accelerate production and prevent downtime. This capital will support efforts to rapidly scale AI in manufacturing by productizing disruptive technology into an instantly deployable solution, enabling faster Clean-in-Place (CIP) and product changeovers.

The company’s technology ingests 1 million data points per second, giving customers like Unilever, AB InBev, The Coca-Cola Company, and Danone real-time monitoring that recaptures previously wasted production time, water, energy, and chemicals. Motivated by the fast realization of ROI, AB InBev, the world’s largest beer company, is currently scaling H2Ok to all six geographical zones and all global breweries in the coming years.

Read more at Business Wire

🇩🇪 36ZERO Vision raises €3.6M to expand AI visual inspection platform /Tech EU/

Want more? Check out the paid analysis delivered weekly below 👇