Batteries Not Included For Quality & Efficiency

Building battery cell manufacturing facilities comes without batteries included. Manufacturers must select their own sites, designs, contractors, and equipment to achieve aggressive production ramps.

Shop Talk

Capturing this week's zeitgeist

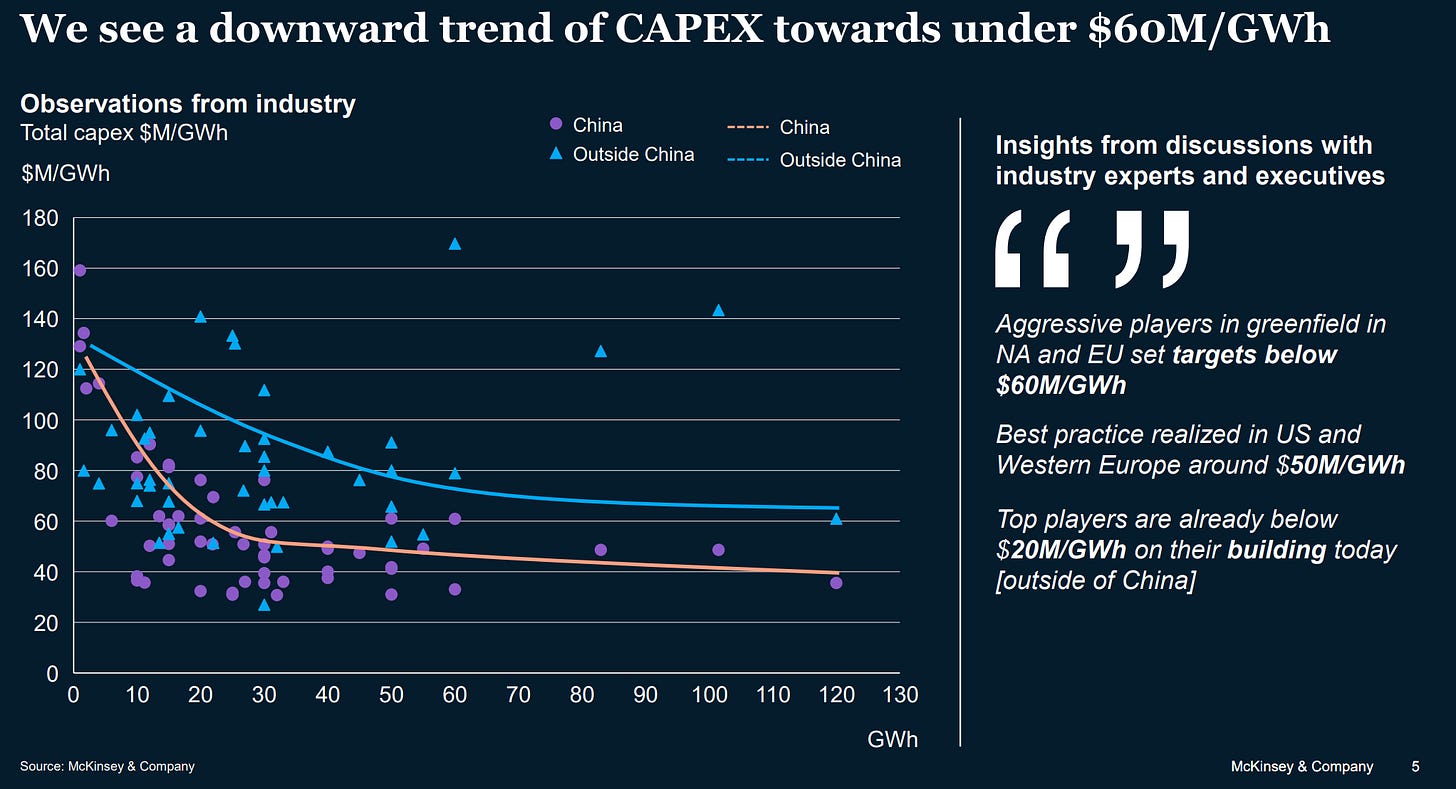

The industrialization challenge of building new production facilities is a significant risk to profitability. McKinsey benchmarking shows the best battery cell facility builders are 2x faster time to market, 3x more CAPEX efficient, and operate with >30% less OPEX. As Battery Bits puts it, “price declines as a function of learning rate are typically perceived to be due to economies of scale but technology and native technology development play a more foundational role.”

Each manufacturing sector has unique build requirements. With an ongoing factory boom, we covered some key considerations for transforming a plot of land into a fully functioning, high-tech factory in our latest weekly post:

When it comes to LK-99, researchers are struggling to replicate it with the appropriate purity to achieve the desired qualities. More on what makes it hard mid-week. Wired and Axios have the latest coverage.

Assembly Line

This week's most influential Industry 4.0 media

🔋 High-Tech Tools Ensure Quality at Battery Manufacturer

📅 Date: August 5, 2023

✍️ Author: John Sprovieri

🔖 Topics: Connected Worker

🏢 Organizations: CATL, Desoutter

CATL’s emphasis on state-of-the-art technology extends even to the fastening tools on its assembly lines. From a fastening standpoint, EV batteries pose several challenges. One is high-mix production. Tools must be able to quickly switch between assembly lines. Tools must accommodate a relatively large torque range and be adaptable to diverse tightening requirements.

Desoutter has worked with CATL from the early stages of its development, helping the company to establish robust tightening standards and improve existing tightening processes. Desoutter supplied CATL with a variety of fastening technologies, including the CONNECT platform, Nexonar positioning system, ERS electric screwdrivers, CVI3 controller, and automatic screw feeders.

Desoutter’s Nexonar 3D spatial positioning system uses infrared sensors to accurately monitor and locate fastening tools or the position of an operator’s hands in critical assembly processes to within 1 millimeter. Nexonar ensures that all screws are tightened in the right place, in the intended sequence, and with the appropriate parameters. The system can be retrofitted to existing tools. It is able to detect the pitch, roll, and yaw of the tool. Several hundred trackers can be monitored simultaneously in real-time and with no latency. It can also be used to ensure accurate part picking, placement, and fulfillment in kitting operations.

Read more at Assembly

🔋 Battery pack assembly line powered by Process Simulate software and the Industrial Metaverse

🧼 Colgate-Palmolive: Successfully Scaling Technology Worldwide

📅 Date: August 1, 2023

✍️ Author: Dennis Scimeca

🏢 Organizations: Colgate-Palmolive, Augury, Twin Thread, Augmentir

Colgate-Palmolive’s secret to successfully scaling manufacturing technologies is simple. Don’t have any secrets. Almost a dozen technology pilots currently run on the Colgate side of the company with the results shared freely to anyone in Pruitt’s community of practice. When everyone knows what everyone else is doing, with no secrets about which pilots take place and their results, it’s easy to get plant managers excited and lined up to scale the technologies.

Centrally led discoveries include the Augury predictive maintenance system. Pruitt and his colleague Gary Binstock discovered Augury at the American Manufacturing Summit in Chicago. The wireless predictive maintenance system uses IoT sensors to monitor machine vibration and detect mechanical problems by comparing that information to a database of vibration data gathered from identical machines at other locations.

Or take, for another example, Colgate-Palmolive’s digital twin system, developed in partnership with the software company Twin Thread. Colgate-Palmolive wanted a system that would automatically adjust production parameters based on quality assessment data. After an 18-month development process, Colgate-Palmolive piloted the IIoT-based digital twin at a Hills Pet Nutrition plant in India.

When Pruitt and his team rolled out in North America the Augmentir system that digitizes standard operating procedures (SOPs), work instructions and checklists for operators to review on mobile devices, engineers from plants in India and Vietnam saw the successful deployments in North America and scaled Augmentir to their own plants.

Read more at Industry Week

🖨️ AI and 3D printing: Ai Build’s Daghan Cam and Luke Rogers on simplifying large-format 3D printing with AI

📅 Date: August 2, 2023

🔖 Topics: Additive Manufacturing, Large Language Model

Ai Build has already partnered with a number of leading 3D printer hardware manufacturers, including Hans Weber Maschinenfabrik, Meltio, KUKA, Evo3D, CEAD, and Massive Dimension. Through these partnerships, the company incorporates a wide range of large-format 3D printers into their Ai Lab workshop. Here, the hardware is used to test, develop, verify, and integrate Ai Build’s software for a growing range of applications. Whilst Cam could not disclose too many names, global engineering solutions firm Weir Group and aerospace manufacturer Boeing were pinpointed as key customers employing AiSync software.

Ai Build’s key product is its AiSync software, an AI-driven toolpath optimization, and quality control platform. Regarding toolpath optimization, it was announced earlier this year that Ai Build had developed a process that allows users to create advanced 3D printing toolpaths using natural language prompts. This feature, called Talk to AiSync, allows users to input simple text, such as “slice the part with 2mm layer height.” This text is then translated into machine instructions to produce the desired 3D-printed part. The key to this feature is large language AI models. AiSync uses OpenAI on the back end, with GPT-4 running the software’s natural language processing. “

Read more at 3D Printing Industry

🦾🖨️ This 3D Printed Gripper Doesn’t Need Electronics To Function

🗜️ Can OES Provide Inclusion Analysis during Steel Production?

📅 Date: August 1, 2023

✍️ Author: Wilhelm Sanders

🔖 Topics: Nondestructive Test

🏭 Vertical: Primary Metal

🏢 Organizations: Thermo Fisher

Non-metallic inclusions are of considerable importance for the steel industry due to the dramatic influence that even small amounts of them may have on the properties, mechanical and otherwise, of the metal or on the production process itself. Inclusions can have positive effects and may increase the value of the steel, but most often inclusions signify quality problems and reduced value.

The modern reference for inclusion analysis is the SEM/EDX (scanning electron microscope coupled with energy-dispersive X-ray fluorescence spectroscopy). This analytical process typically takes several hours, including sample preparation and interpretation, which is far too long to be applicable to production control.

Within recent years we’ve seen the development of extremely fast and economical OES (optical emission spectrometry) methods which are able to provide inclusion information even during the steel production process. The method uses the principle of Single Spark Acquisition (SSA), where signals from the individual “single sparks” are not summed as in conventional OES acquisition, but processed with special algorithms.

Read more at Thermo Fisher Blog

🧠 How generalized AI outperforms specialized models

🧠 How MIT’s Liquid Neural Networks can solve AI problems from robotics to self-driving cars

📅 Date: August 2, 2023

✍️ Author: Ben Dickson

🏢 Organizations: MIT

Liquid neural networks, a novel type of deep learning architecture developed by researchers at the Computer Science and Artificial Intelligence Laboratory at MIT (CSAIL), offer a compact, adaptable and efficient solution to certain AI problems. These networks are designed to address some of the inherent challenges of traditional deep learning models.

Liquid neural networks represent a significant departure from traditional deep learning models. They use a mathematical formulation that is less computationally expensive and stabilizes neurons during training. The key to LNNs’ efficiency lies in their use of dynamically adjustable differential equations, which allows them to adapt to new situations after training. This is a capability not found in typical neural networks.

This significant reduction in size has several important consequences, Rus said. First, it enables the model to run on small computers found in robots and other edge devices. And second, with fewer neurons, the network becomes much more interpretable. Interpretability is a significant challenge in the field of AI. With traditional deep learning models, it can be difficult to understand how the model arrived at a particular decision.

Read more at VentureBeat

🦾 Mitsubishi Electric & SICK Sensor Intelligence: Conveyor Tracking with Zoned Safety

🎛️ Optimal control of the part mass for the injection molding process

📅 Date: August 2, 2023

✍️ Authors: Jakob Maderthaner, Andreas Kugi, Wolfgang Kemmetmüller

🔖 Topics: Injection Molding, Model Predictive Control

Injection molding is one of the most important processes in manufacturing plastic goods. During the long production times, process variations might lead to varying product quality. Therefore, in the state of the art, the machine variables of injection molding machines (e. g. the barrel temperature and the screw speed) are controlled to suppress these variations. However, the influence of changes in the raw material on the part quality cannot be systematically suppressed with state-of-the-art controllers. In this work, a novel control concept is proposed where the part mass is controlled instead of the usual machine variables. The control strategy is based on an estimation of the mass of the plastic in the mold. In order to account for the system’s nonlinearities, a model predictive control strategy is developed for both the filling and the holding-pressure phases. The feasibility and the benefits of this proposed part-mass control strategy are evaluated by a series of measurements on an electric injection molding machine.

Read more at the Journal of Process Control

Capital Investment

Major factory investments and line commissions. Tracked in the Atlas.

🏭🇩🇪 Thyssenkrupp to win EU nod for $2.3 bln German steel subsidies

📅 Date: July 18, 2023

✍️ Authors: Foo Yun Chee, Christoph Steitz

Thyssenkrupp (TKAG.DE) is set to secure EU approval for 2 billion euros ($2.3 billion) of German state subsidies for its proposed green steel plant in Duisburg. Thyssenkrupp requires financial support for the so-called direct reduction iron (DRI) plant, which is vital to cutting CO2 emissions during the production of steel, one of the most polluting industrial manufacturing processes. The DRI site is due to start operation at the end of 2026 and forms the center of Thyssenkrupp’s effort to decarbonize production at its steel division, which is currently looking for a strategic partner.

Read more at Reuters

🏭🇺🇸 MIT researchers to lead a new center for continuous mRNA manufacturing

📅 Date: July 13, 2023

The main goal of the project is to advance the field of mRNA therapeutics by providing a continuous manufacturing template for companies to follow while facilitating collaboration throughout the biopharmaceuticals industry. The research team will also work closely with the FDA to ensure the pilot-scale system adheres to current good manufacturing practices and informs regulatory strategies. All of this helps significantly de-risk the development of mRNA technology.

A significant portion of the project has been subcontracted to ReciBioPharm as it builds the manufacturing facility. Work at MIT is already underway to develop automation and advanced controls for quality assurance and improve midstream processing.

Read more at MIT News

🏭🇺🇸 Twelve Commences Construction of First Commercial-Scale Plant in the US for Producing Sustainable Aviation Fuel from CO2

📅 Date: July 12, 2023

Twelve, the carbon transformation company, today broke ground on its commercial-scale E-Jet® fuel production facility in Moses Lake, Washington. E-Jet fuel is SAF produced using Twelve’s revolutionary carbon transformation technology, which uses only renewable energy and water to transform CO2 into critical chemicals, materials, and fuels conventionally made from fossil fuels, and in partnership with Emerging Fuels Technology. As a power-to-liquid SAF with up to 90% lower lifecycle greenhouse gas (GHG) emissions compared to conventional, petroleum-based jet fuel, E-Jet fuel meets the applicable ASTM International specifications and is a drop-in ready synthetic fuel that works seamlessly with existing aircraft and airport infrastructure. It faces no real constraints on feedstock, thus offering the best viable long-term solution for addressing GHG and other emissions from the aviation sector.

Read more at Business Wire

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains

🗜️ Sustainable Steel Startup Hybar Raises $700 Million

📅 Date: August 2, 2023

🔖 Topics: Funding Event

Hybar, a newly formed company, announced today that it successfully raised $700 million of debt and equity financing to build, start-up, and operate a technologically advanced, environmentally sustainable scrap metal recycling steel rebar mill. The equity portion of the financing was led by TPG Rise Climate, the dedicated climate investing strategy of TPG’s global impact investing platform TPG Rise, and Global Principal Partners, the investment entity used by Hybar’s senior management team.

Of the $700 million raised, $470 million will be spent to build the rebar mill. The remainder of the financing will be used to start up and operate the mill and pay certain debt service costs during construction. The mill, which is expected to take 22 months to construct, is being built in northeast Arkansas on a 1,300-acre greenfield site with direct access to barge, rail, and truck transportation options. The mill will produce a full complement of high-yielding rebar that will primarily be used in large infrastructure projects, including projects supported by the Infrastructure Investment and Jobs Act and the Inflation Reduction Act.

Read more at PR Newswire

⚗️🧠 Chemify Announces $43 Million of Funding to Digitize Chemistry

📅 Date: August 2, 2023

Chemify, a pioneering company operating its proprietary molecular design, discovery, and chemical manufacturing technology to provide pharmaceutical, biotechnology, and industrial partners with better molecules, today announced funding of $43 million including a Series A led by Triatomic Capital, joined by new investors including Hong-Kong based Horizon Ventures, US-based Rocketship Ventures, Possible Ventures, Alix Ventures, Scotland-based Eos, and the UK Government Innovation Accelerators program. Existing investor BlueYard Capital also participated in the round.

Founded in 2019 by CEO Lee Cronin with backing from David Cleevely (co-founder of Abcam), Chemify is based on decades of chemistry research, robotics, AI, and conceptual advancements from Cronin’s Digital Chemistry Laboratory at the University of Glasgow in Scotland. Professor Cronin’s pioneering research spans the digitization of chemistry including the use of artificial intelligence in chemistry to explore ‘chemical space’ - to access and create the trillions of possible combinations of natural elements. Chemify can help reduce the amount of costly and time-consuming experimentation required to discover promising new molecules, speeding up their development as products to underpin advances in medicine, farming, materials science, and green energy.

Read more at Business Wire

⛏️ International investors pile into BHP-backed mining tech start-up, Plotlogic

📅 Date: July 31, 2023

BHP-backed mining tech start-up Plotlogic has banked a $US28 ($43 million) series B funding round, co-led by Galvanise Climate Solutions, a US-based investment firm founded by former Democratic presidential candidate Tom Steyer and SE Ventures, the venture arm of French energy and automation giant Schneider Electric.

Founded in 2018 by ex-mining executive Andrew Job while doing his Ph.D. at the University of Queensland, Plotlogic uses advanced sensors and artificial intelligence to determine the quality of minerals and metals. Mr Job said Plotlogic’s revenue had increased 10-fold over the past 10 months and the technology was being used by the likes of BHP, Brazilian miner Vale, South32, and leading lithium company Pilbara Minerals to help increase output and reduce waste.

Plotlogic’s OreSense technology combines LIDAR (laser-based light detection and ranging hyper-spectral imaging) and machine-learning algorithms to deliver a more accurate view of an orebody.

Read more at Australian Financial Review

☀️ Solar Startup GlassPoint Lands $8 Million After a Reboot

📅 Date: July 31, 2023

✍️ Author: Yuliya Chernova

A solar startup that has gotten a second lease on life is back with a new strategy aimed at helping it better cope with future downturns. GlassPoint, which sells solar-generated steam for industrial uses, is one of several businesses chasing climate-tech ideas that struggled in the past, but now expect better results amid greater focus on carbon emissions reductions.

The new version of GlassPoint has raised $8 million in a Series A round led by new investor 300PPM. Former Australian Prime Minister Malcolm Turnbull participated in the financing, along with Tomas Sigurdsson, former chief operating officer of Alcoa.

Read more at Wall Street Journal

♻️💻 Material breakthrough will facilitate electronics recycling

📅 Date: August 2, 2023

✍️ Author: Emily Atkins

A UK-based materials specialist has produced a circuit board substrate that dissolves in water, allowing the components to be recovered and recycled. Jiva Materials Ltd has developed a patented, fully recyclable printed circuit board (PCB) substrate it calls Soluboard. The company recently secured £1 million ($1.7 million) in funding to commercialize the product.

The organic structure of Soluboard means the non-toxic ingredients begin to delaminate when immersed in hot water. This allows the natural plant-based fibers to be composted, the remaining solution to be disposed of using standard domestic wastewater systems and the electronic components to be removed for re-processing.

Read more at Waste Recycling Magazine

🚀 2023 NASA Tipping Point Selections

📅 Date: July 24, 2023

NASA has selected 11 U.S. companies to develop technologies that will support long-term exploration on the Moon and in space under its sixth Tipping Point opportunity. The total expected NASA contribution to the partnerships is $150 million. Each company will contribute a minimum percentage, based on company size, of the total project cost. NASA’s Space Technology Mission Directorate (STMD) will issue milestone-based funded Space Act Agreements lasting for up to four years.

Read more at NASA Directorates