Assembly Intelligence Required

This week: Deep learning on PLCs, rethinking the box, what happens in planned maintenance, injection molding parameter prediction, an artificial sun, AI-powered root cause, yard ops, and robotics.

Shop Talk

Capturing this week's zeitgeist

As part of our ongoing commitment to enhance the overall security of our products, we are introducing an authorization and authentication protection mechanism for the connection and control of Bambu Lab 3D printers. This step is a significant security enhancement to ensure only authorized access and operations are permitted.

via "Firmware Update Introducing New Authorization Control System”

Following intense backlash over the digital rights management implementation, Bambu issued a clarifying announcement addressing the community's concerns:

We want to make it absolutely clear that all of these claims are entirely false:

Bambu Lab will remotely disable your printer ("brick" it).

Firmware updates will block your printer’s ability to print.

AMS functionality will be restricted, and the use of third-party filament will be disabled.

Bambu Lab firmware contains trojans or backdoors for unauthorized remote control.

The printers have a timed killswitch that disables them after a certain period.

All 3D files printed are monitored, duplicated, or stolen.

A subscription will be mandatory to use your printer.

via “Updates and Third-Party Integration with Bambu Connect”

Assembly Line

This week's most influential Industry 4.0 media.

📸 Implementing a Workflow for Deploying and Integrating Deep Learning Networks on PLCs for Industrial Automation

✍️ Authors: Fabian Bause, Nicolas Camargo Torres

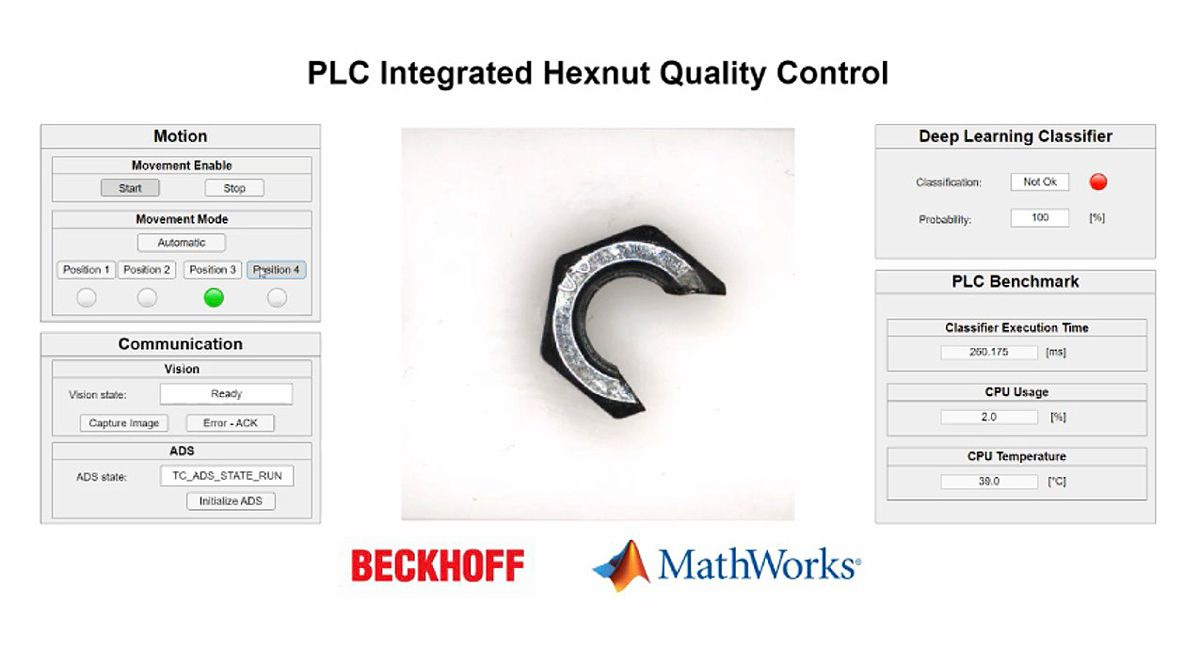

Our team at Beckhoff Automation has implemented a new workflow that combines MATLAB® tools and Beckhoff Automation products to enable low-code design and AI model training—and simplifies the deployment and integration of those models onto PLCs. Working with MathWorks engineers, we developed this workflow and demonstrated it on an example quality control application that involved the visual inspection of hex nuts. While this simple application classifies hex nuts as either defective or not, demonstrating a straightforward use case, the steps in the workflow can be applied to accelerate the development and deployment of much more sophisticated and complex applications.

After collecting and preparing the data to be used in a deep learning application, the workflow’s first step is training a deep learning model. With MATLAB and Deep Learning Toolbox, there are several ways to do this, including training a network from scratch with Deep Network Designer app, defining a deep learning model as a function and using a custom training loop, or retraining a pretrained model with new data, also known as transfer learning. If there is a small amount of abnormal data, anomaly detection methods such as FCDD and PatchCore, which are included in the Automated Visual Inspection Library for Computer Vision Toolbox™, are also effective.

Read more at MathWorks

🦾 Automate or don’t automate that is the question:

Adopting machine monitoring helped LeClaire Manufacturing boost its vertical CNC utilization rates 38 percentage points and gain millions in revenue. [MMS]

To democratize robotics, AI for industrial applications need to be accessible to any engineer to customize, enhance and program without the need for expensive specialist consultants or extensive retraining on proprietary systems. [AW]

Teradyne Robotics and Analog Devices Enter Strategic Partnership [Business Wire]

Comau’s electric drive doubles Geely Vremt’s automation rate [Comau]

Freespace Robotics Announces Strategic Partnership with high-turnover, small-footprint, high-rise AS/RS leader Matthews Automation Solutions [Freespace]

A Design Engineer’s Tour of Zebra Technologies’ R&D Facility

📦 Rethinking the Box

But as the low-hanging fruit of last-mile optimization is picked, and companies hunt for small-but-mighty efficiency improvements that yield meaningful cost savings and sustainability benefits, they’re asking: How much scarce, costly warehouse square footage is eaten up by packaging inventory? How many more orders might fit on a truck if cartons were right-sized? How many truck trips might be eliminated? How much less fuel consumed? How much money saved in parcel freight charges? How many more orders could be filled by the same workforce in the same workday with less risk of damage?

The issue is not, however, always wasted space. Getting the pack wrong can also be costly. As an example, Larsen worked with a maker of dog food that was shipping its product in quantity in heavy-grade, lightweight poly-bags. While the bags had no void or fill, the total bag weight, size and sorting/handling limitations (they could not be run through the normal conveyor/sorter system) triggered high accessorial charges in the carrier rate tables. A shift in packaging strategy to low-profile boxes generated quick savings. On average, he says, shippers could see 5-20% savings from studying the tables closely and taking advantage of size or weight thresholds to split or reconfigure shipments to reduce dimensional or DIM rates and charges — or to challenge a carrier’s interpretation of the tables.

Read more at SupplyChainBrain

🧑🔧 Aurubis completes largest planned maintenance shutdown at Hamburg plant

🧠 Development of an injection molding production condition inference system based on diffusion model

✍️ Authors: Joon-Young Kim, Heekyu Kim, Keonwoo Nam

🏢 Organizations: Korea Advanced Institute of Science and Technology

Plastic injection molding is a crucial process for the mass production of various products. However, traditional methods for setting production conditions have heavily relied on skilled operators to adjust parameters through trial and error. This approach is not only inefficient but also results in inconsistent quality control. To address these challenges, this study proposes a new machine learning based model that automatically infers process parameters, enabling real time adaptation to external environmental changes. A surrogate model is first developed to learn the relationship between process parameters, environmental variables, and product quality, predicting whether a given set of parameters will result in a good or defective product. Building on this, a diffusion model, a type of deep generative model, was employed to generate diverse sets of process parameters likely to yield defect free products under specific environmental conditions.

Read more at Journal of Manufacturing Systems

🧠 Developing assembly intelligence:

Basetwo closes $16.5-million CAD Series A round to optimize manufacturing with AI copilots [BetaKit]

Engineers at the University of Virginia (UVA) are using multi-agent reinforcement learning (MARL) to transform how factories operate. [ASSEMBLY]

Generative AI-powered Root-Cause Problem-Solving in Manufacturing [oee.ai]

A generative pre-trained transformer industrial bot to improve operators’ working experience in a small Industry 5.0 factory [The International Journal of Advanced Manufacturing Technology]

New Product Introduction

Highlighting new and innovative facilities, processes, products, and services

☢️ Chinese 'artificial sun' sets new record in milestone step toward fusion power generation

🏢 Organizations: Chinese Academy of Sciences

The Experimental Advanced Superconducting Tokamak (EAST), dubbed China’s “artificial sun,” maintained a steady-state high-confinement plasma operation for a remarkable 1,066 seconds, setting a new world record and marking a breakthrough in the quest for fusion power generation.

The duration of 1,000 seconds is considered a key step in fusion research. The breakthrough, achieved by the Institute of Plasma Physics under the Chinese Academy of Sciences (ASIPP), greatly improved the original world record of 403 seconds, which was also set by EAST in 2023.

Global scientists have worked for more than 70 years on trying to achieve this feat. However, only after reaching temperatures over 100 million degrees Celsius, sustaining stable long-term operation, and ensuring controllability can a nuclear fusion device successfully generate electricity.

Read more at Xinhua

🇨🇳 He who rides a tiger is afraid to dismount:

How Chinese AI Startup DeepSeek Made a Model that Rivals OpenAI [Wired] and released the code under MIT license [deepseek-ai/DeepSeek-R1]

China’s overlapping tech-industrial ecosystems [High Capacity]

ASPI’s Critical Technology Tracker covers China’s global lead in 37 out of 44 critical technologies.

Outrider deploys reinforcement learning AI to enhance distribution yard throughput

Outrider, the leader in autonomous yard operations for logistics hubs, announces its industry-first deployment of advanced reinforcement learning (RL) techniques to maximize freight throughput at customer sites. Outrider’s RL models increase path planning speed by 10x and enable the Outrider System to move freight more efficiently and safely through busy, complex distribution yards.

Processing these data points through DL and RL models requires sophisticated computing hardware and a cost-effective hybrid cloud training environment that leverages public and private AI clouds. Outrider’s private AI cloud deployment utilizes NVIDIA DGX H200 GPUs installed at a secure, Denver-based data center owned and operated by Equinix.

Read more at Outrider

Business Transactions

This week's top funding events, acquisitions, and partnerships across industrial value chains.

🇩🇪 Sereact raises €25M to boost AI-powered robotics

At Sereact, we are on a mission to redefine what’s possible with AI-driven robotics. This marks a major milestone in our journey as we secure €25 million in Series A funding. The Series A round was led by Creandum, alongside significant participation from existing investors Point Nine and Air Street Capital, and prominent business angels, including former Formula 1 World Champion Nico Rosberg, Mehdi Ghissassi (ex Google DeepMind), Ott Kaukver (Skype), Lars Nordwall (ex neo4j), Rubin Ritter (ex Zalando), Torsten Reil and Niklas Köhler (both Helsing).

This funding will allow us to accelerate our mission in several key areas:

Expanding R&D efforts to support additional robotic platforms, including mobile robots and humanoids.

Developing AI solutions for more complex tasks beyond logistics and manufacturing.

Expanding our U.S. presence, building strategic partnerships, and growing our local team.

Read more at Sereact