3D Printing, AI, Robots, and the Meaning of Their Venn Diagram Overlaps

Manufacturing today is a system of separately proven elements operating together. A different mode of manufacturing tomorrow brings these digital elements together into a single thing.

The future of manufacturing may be here already in all the requisite pieces, just not fully interconnected yet. A different mode of part production we may come to understand and employ in the next decade will involve three elements—additive manufacturing + artificial intelligence + robots—all working together as one interconnected thing.

(Inspiration credit: I thought about this when I read the news of a 3D-printable robot introduced by an AI company. It’s not an industrial robot, but those three elements reshaping industry are all there.)

Two observations point to the likely importance of the AM/AI/robot triad. One is the general way disruptive technologies have their impact: They are not really transformative until they resonate with other disruptors. For example, the internet sort of changed things, cell phones sort of changed things, but what really transformed us was when the internet and cell phones resonated and merged into the devices we now take for granted.

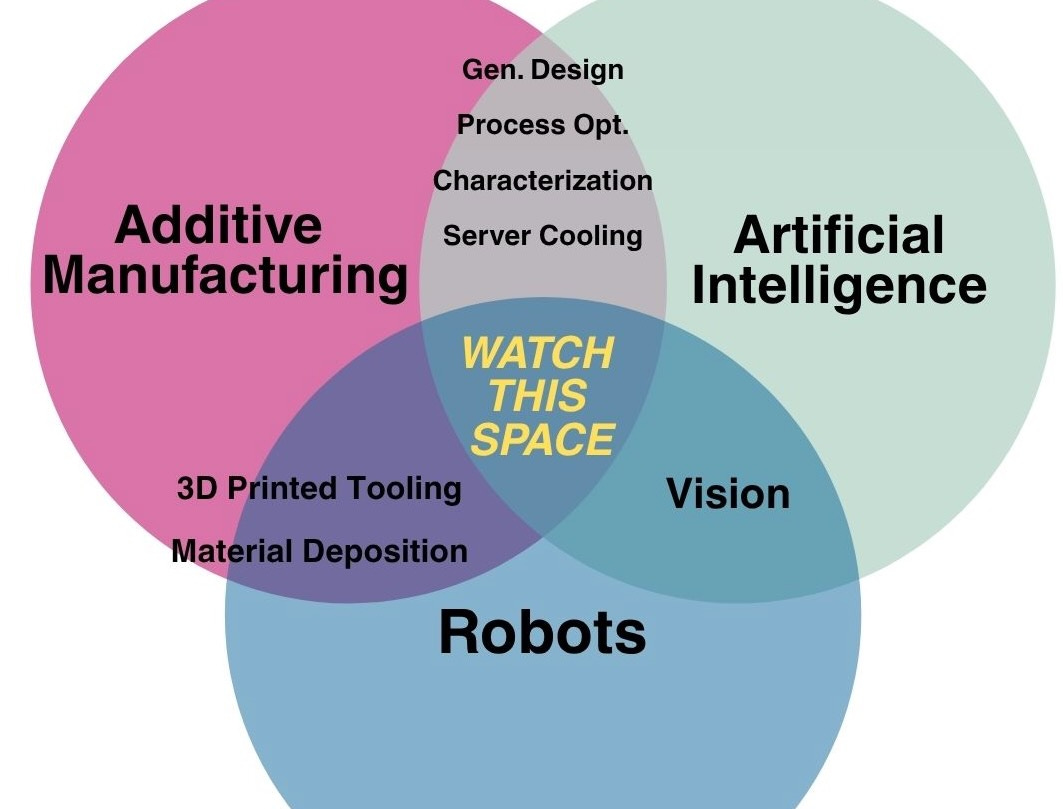

A second observation is the way AM, AI, and robots are already mutually thriving within every pairing within the triad. Each pairing already has an active overlap space. Here are each of the Venn diagram pairings and what they are doing today:

AM + AI: generative design, process optimization, characterization of legacy parts for AM opportunities, not to mention the cooling of the data servers AI requires.

AM + robots: rapid creation of custom robot tooling, manufacturing of robots, 3D printing by robots through deposition

Robots + AI: Vision! AI addresses the data challenge of guiding a robot in real-time via vision technology.

With three Venn diagrams up and running, it is easy to predict that the middle space between all three of these overlaps will begin to grow.

To imagine what this manufacturing might look like and how different it might be, it helps to consider the triad that has already proven successful. The comparable manufacturing triad in use today is something like tooling + tribes + boxes. Production involves hard tooling, it is run and overseen by specialized programmers or craftspeople, and the work is contained within rigid machine frames moving in linear axes.

It is hard to see AM + AI + robots directly replacing that existing triad (it’s not a solution for a million stampings, for example). It is much more likely that the new triad opens up production options unseen before. This production would be highly flexible, lightly staffed, repeatable but non-repeating, self-correcting, self-adapting, time-responsive, and low-volume. Indeed, here is one application that can be readily foreseen, because it fits the way 3D printing via robots is used today: The facility operating by this triad might be where tooling is produced that is useful for production within the previous triad.

Peter Zelinski is a writer who reports on technology advances in discrete part manufacturing. His views are his own.